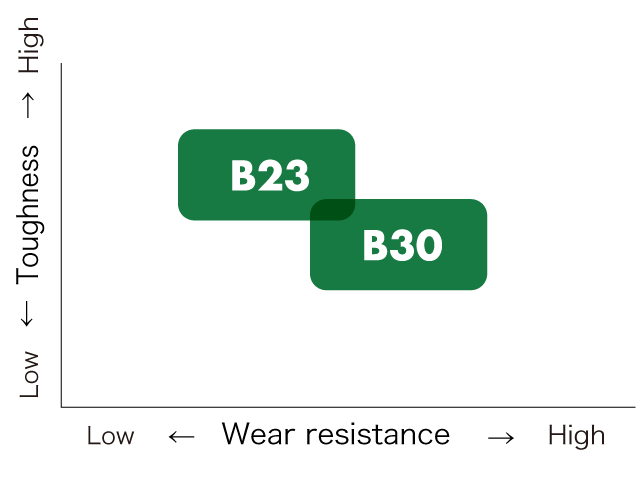

High-speed finishing of gray cast iron| Uncoated CBNs

Gray cast iron

B23 for roughing to semi-finish turning operations

B30 for semi-finish to finish turning operations

| Klasse | Material | Operationstyp | Bearbeitung | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR) | DOC(mm) DOC(inch) | Kühlmittel |

|---|---|---|---|---|---|---|---|

| B23/B30 | Graues Gusseisen | Turning | High-speed finishing | 400 – 1200 1300 – 4000 | 0.1 – 0.5 .040 – .020 | 0.2 – 2.0 .008 – .080 | DRY/WET |

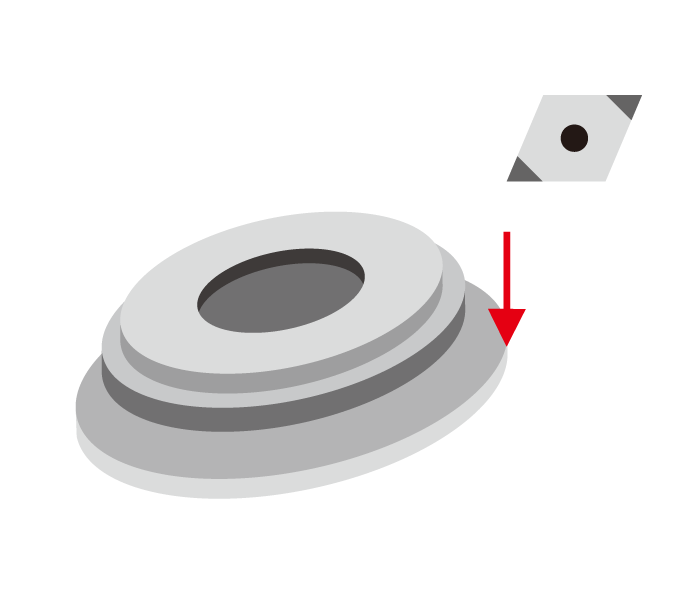

| OD turning of oil pump housing | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| B23 |

210 pcs / corner

|

| Competitor’s CBN |

70 Stück / Ecke

|

The B23 insert was 3 times more productive than the competitor’s insert.

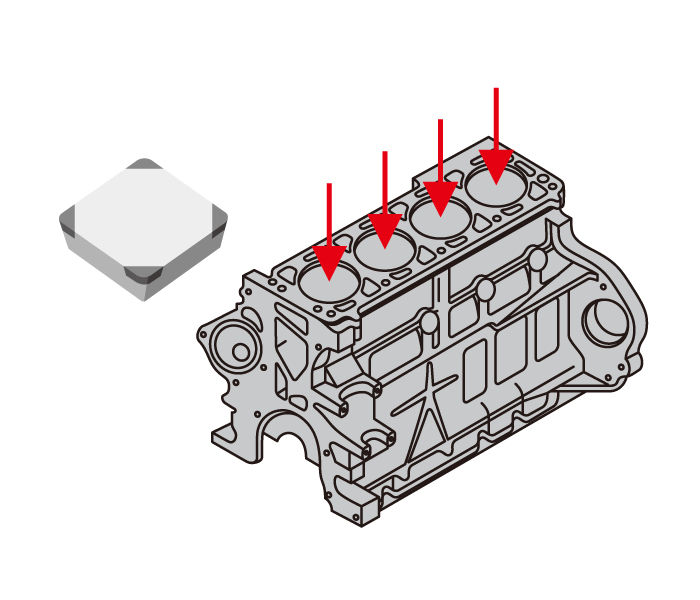

| Continuous ID bore operation on a cylinder block | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| B30 |

800 pcs / corner

|

| Competitor’s CBN |

500 pcs / corner

|

B30 achieved 1.6 times the tool life compared to competitor’s CBN.

Weitere Informationen zu diesem Produkt finden Sie in unserem Online-E-Katalog, oder laden Sie den Katalog/Produktbericht herunter

Andere empfohlene Produkte