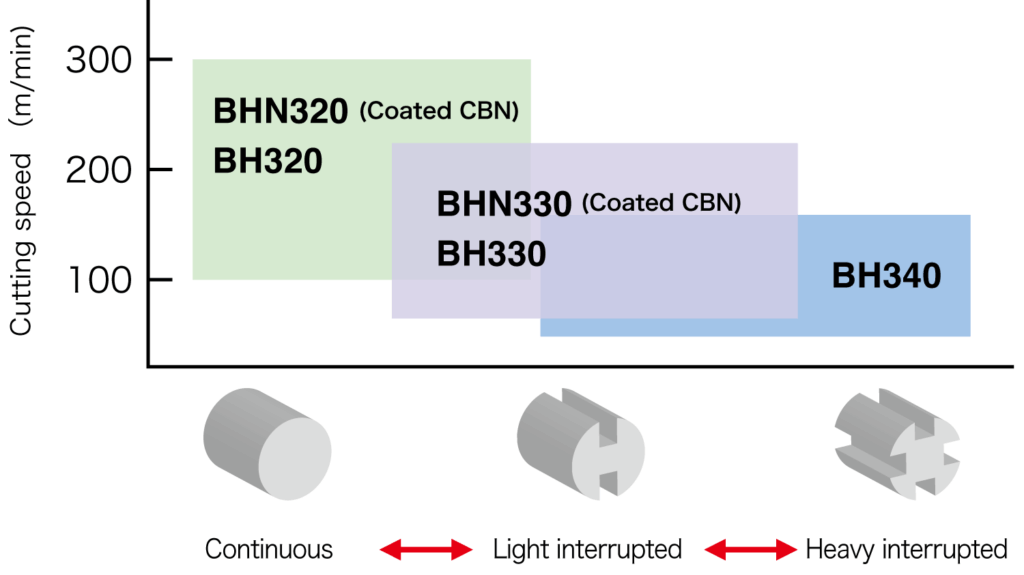

Für die kontinuierliche-leichte Unterbrechungsbearbeitung | CBN für die Bearbeitung von gehärtetem Material

Hardened steel – Finishing

The first recommended material for continuous to light interrupted machining,

with a coating that has excellent wear resistance.

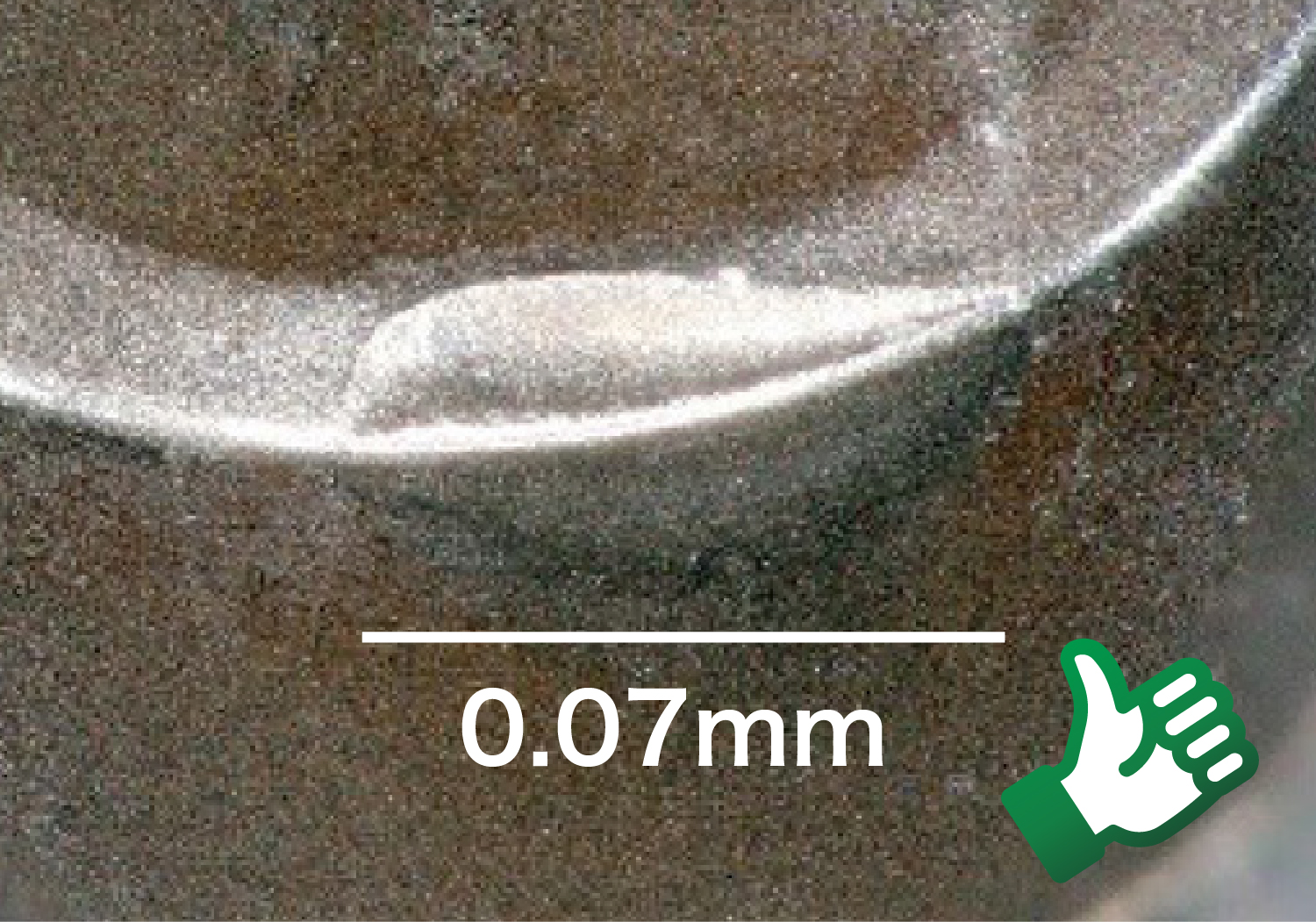

| BHN320 | Competitor |

|---|---|

|

|

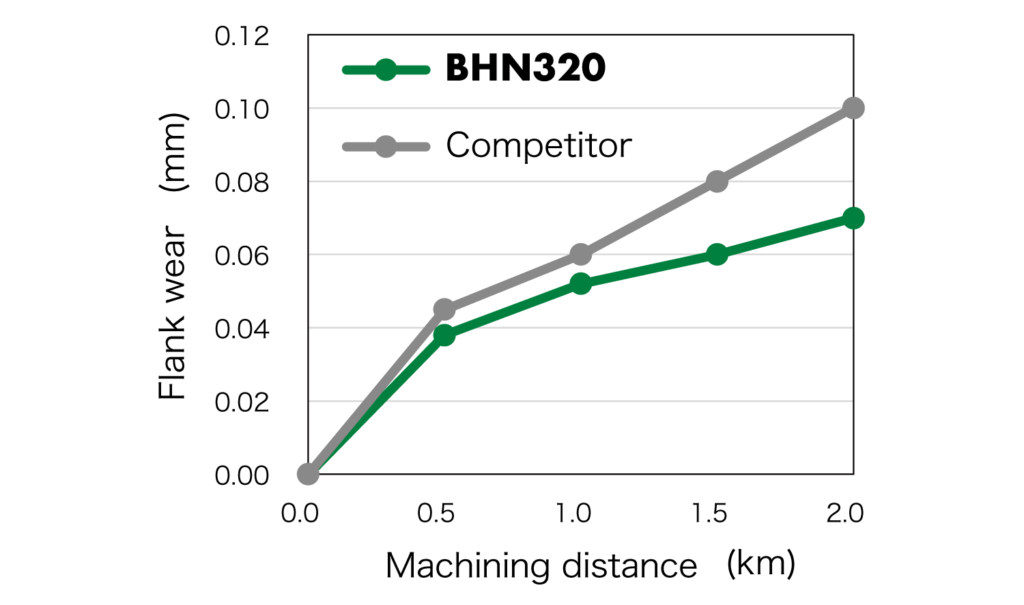

Alloy steel(HRc62)

vc = 150m/min, f = 0.1mm/rev, ap = 0.2mm, Continuous

A multi-layer coating with excellent wear resistance and chipping resistance is used,

making this a versatile material that can be used for continuous to interrupted machining.

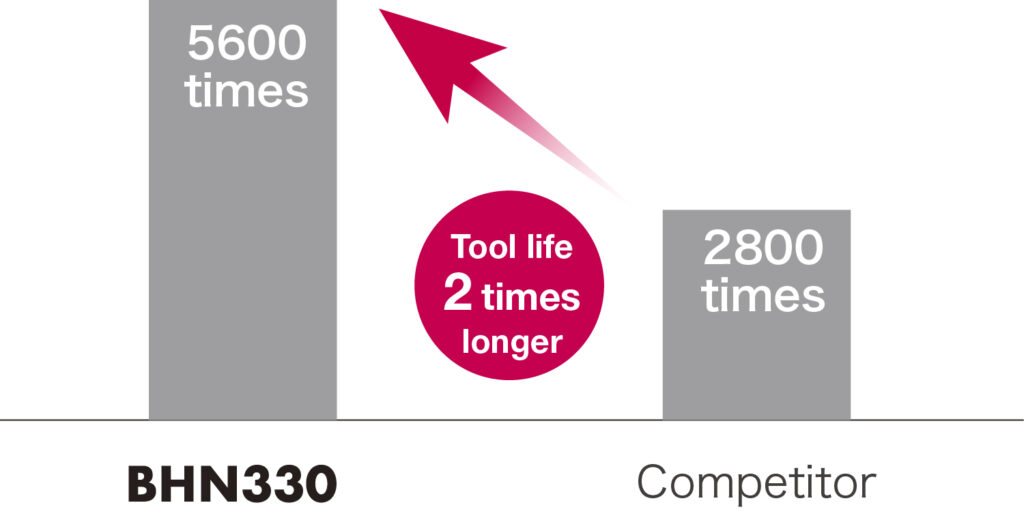

| BHN330 | Competitor |

|---|---|

|

|

| Number of impacts 2800 times | |

Alloy steel(HRc62)

vc = 75m/min, f = 0.1mm/rev, ap = 0.1mm, Heavy interrupted

Number of times until breakage

CBN is bonded with a special binder, providing excellent wear resistance at high speeds and continuous cutting.

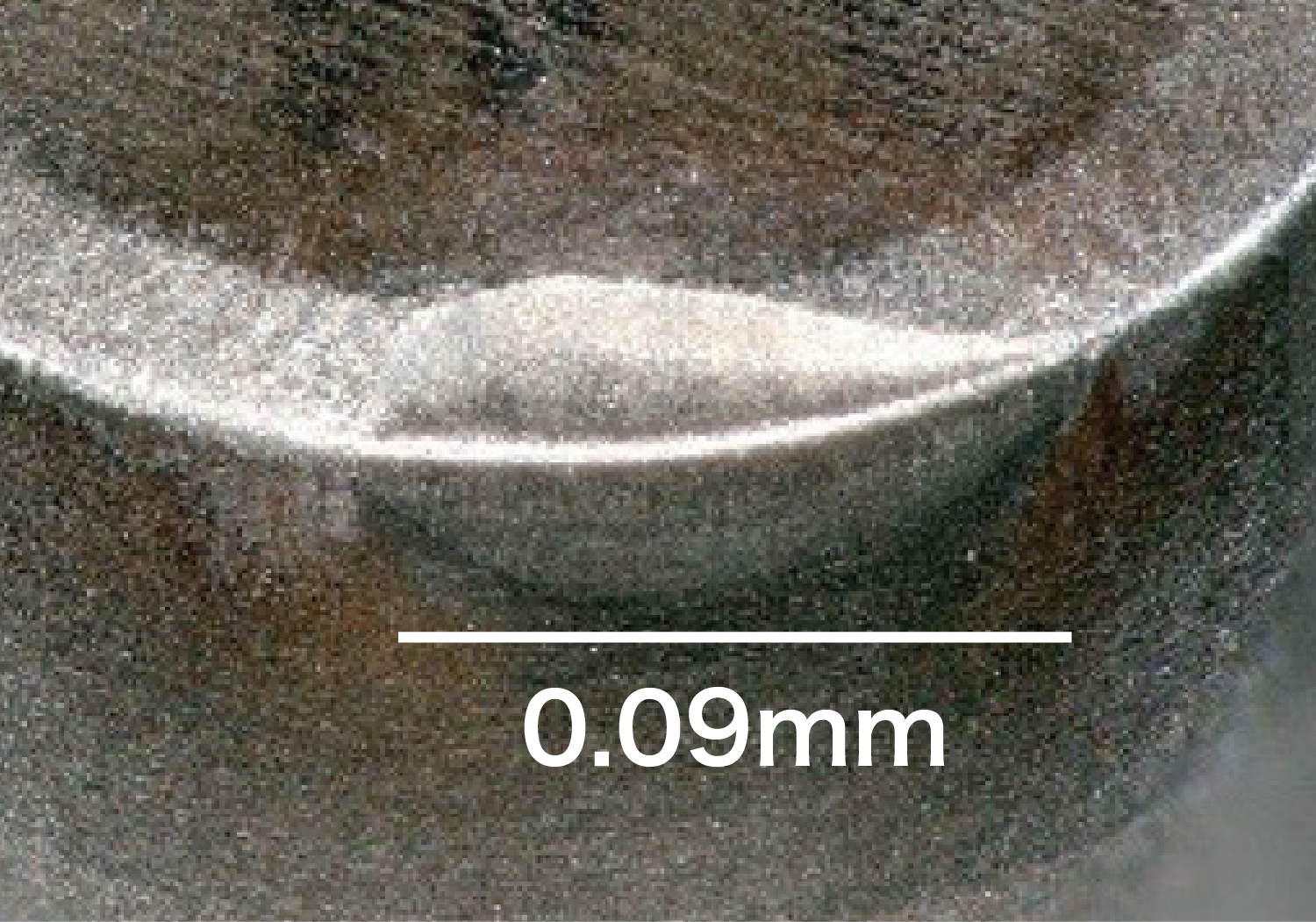

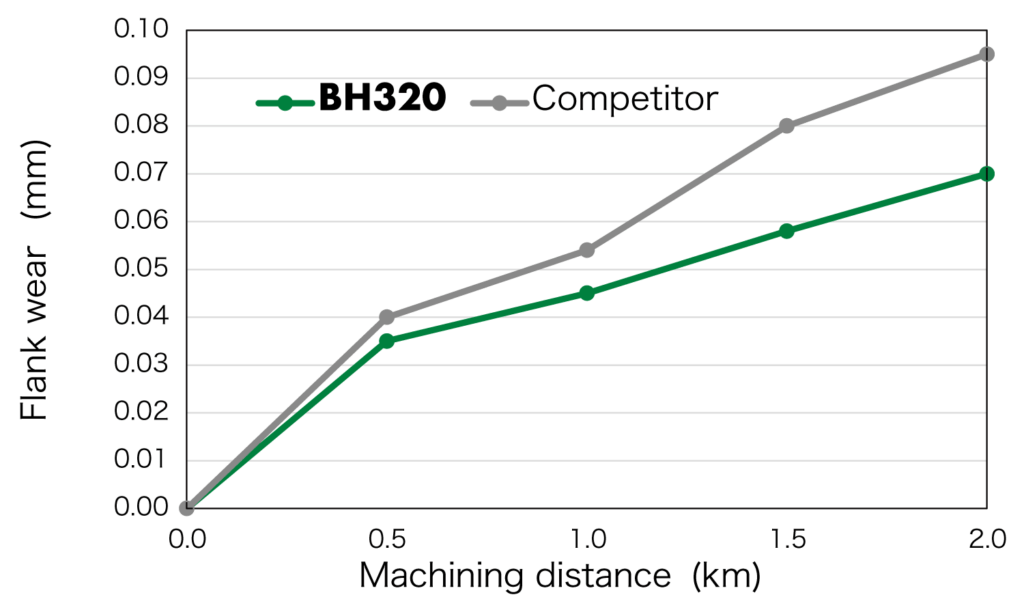

| BH320 | Competitor |

|---|---|

|

|

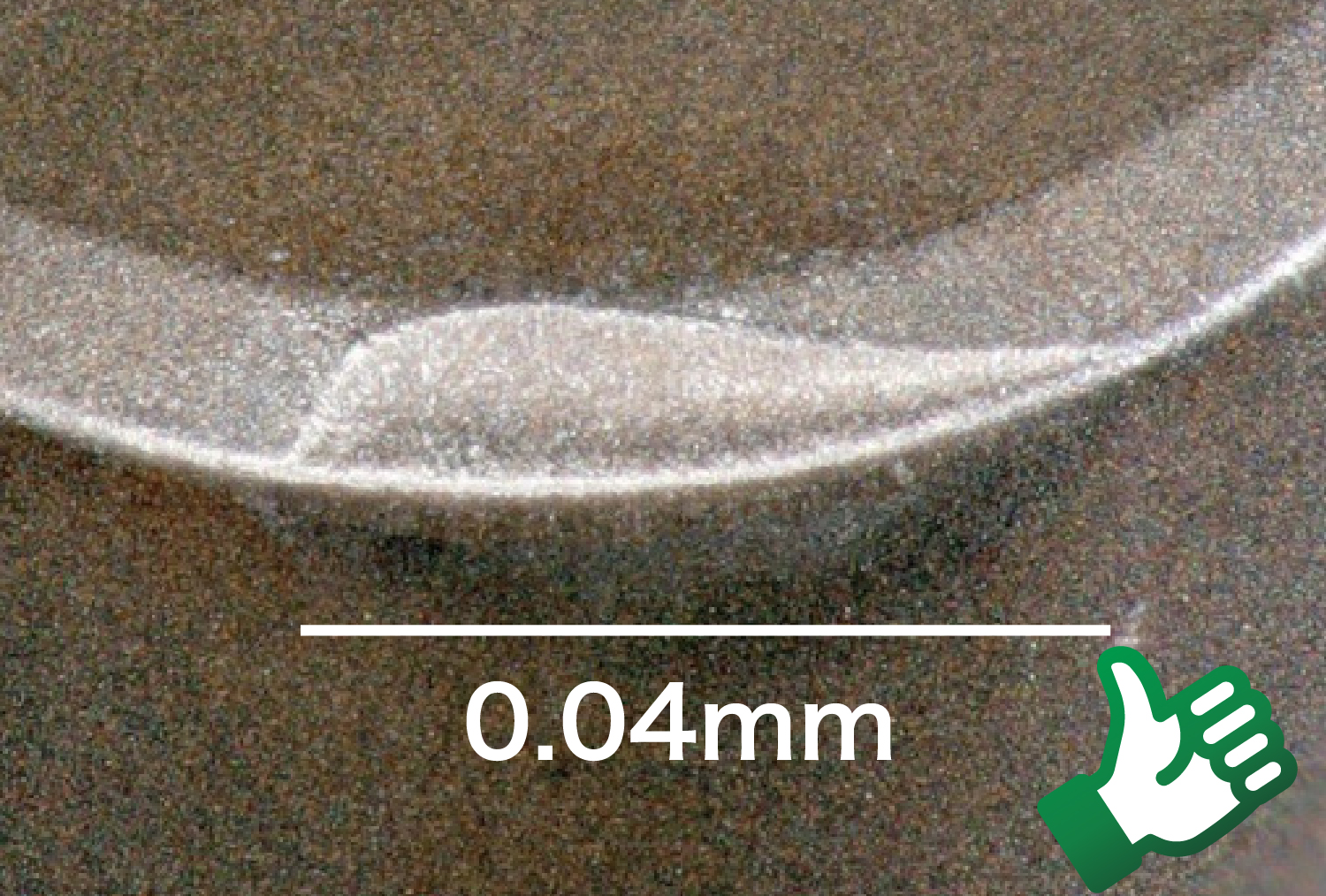

Alloy steel(HRc62)

vc = 150m/min, f = 0.1mm/rev, ap = 0.2mm, Continuous

| BH330 | Competitor |

|---|---|

|

|

Alloy steel(HRc62)

vc = 150m/min, f = 0.1mm/rev, ap = 0.2mm,

After processing 0.7km

| BH330 | Competitor |

|---|---|

|

|

| Number of impacts 3500 times | |

Alloy steel(HRc62)

vc = 150m/min, f = 0.1mm/rev, ap = 0.2mm, Heavy interrupted

High resistance to chipping and fracture, highly recommended for heavy interrupted cutting.

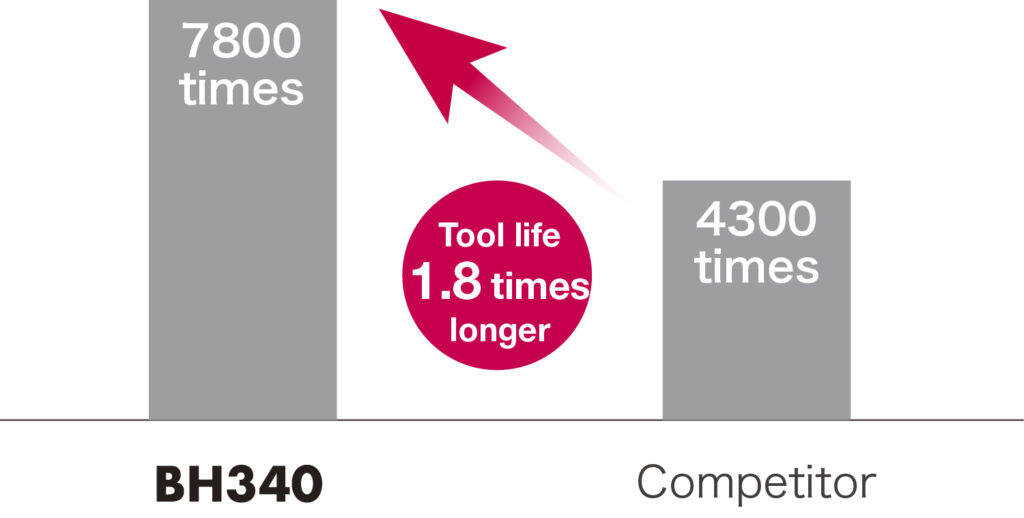

| BH340 | Competitor |

|---|---|

|

|

| Number of impacts 4300 times | |

Alloy steel(HRc62)

vc = 75m/min, f = 0.1mm/rev, ap = 0.1mm, Heavy interrupted

Number of times until breakage

| ●1st Recommendation 〇2nd Recommendation |

||||||

| Interruption length | Recommended material | Cutting speed | Feed | DOC | Machining | |

|---|---|---|---|---|---|---|

| (m/min) (SFM) | (mm/rev) (IPR) | (mm) (inch) | DRY | WET | ||

| Continuous cutting | BHN320 (Coated CBN) BH320 |

100 – 300 330 – 1000 | up to 0.2 .008 | up to 0.5 .020 | 〇 | ● |

| Light interrupt cutting | BHN330 (Coated CBN) BH330 |

75 – 225 330 – 740 | up to 0.15 .006 | ● | 〇 | |

| Heavy interrupted cutting | BH340 | 50 – 150 160 – 500 | up to 0.1 .004 | ● | 〇 | |

| Automotive parts | ||

|---|---|---|

|  | |

| ||

| ||

| ||

| ||

| ||

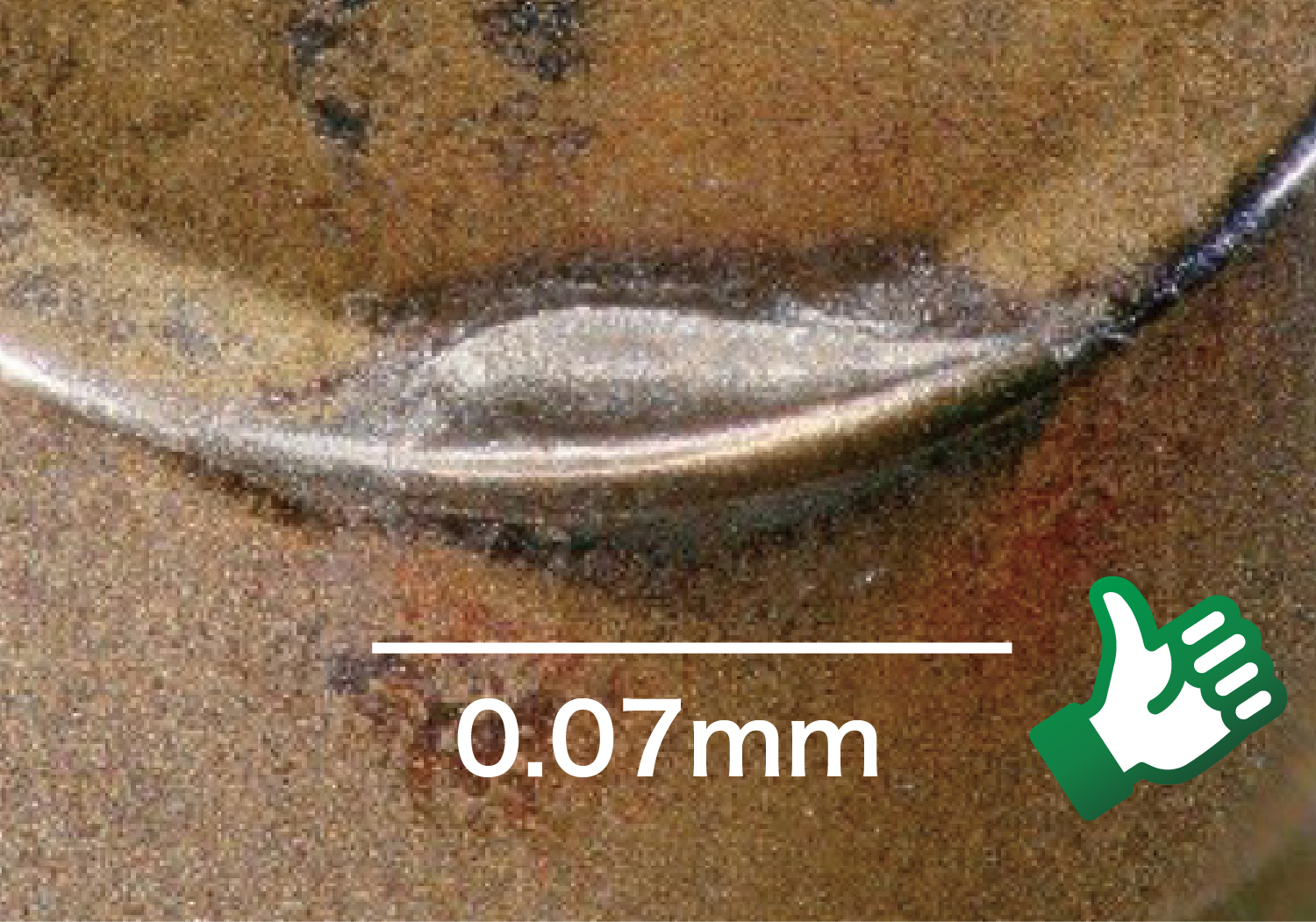

| BHN320 | 400 pcs / corner | |

| Competitor’s CBN | 200 pcs / corner | |

Conventionally, Competitor’s CBN would reach the end of its tool life due to a deterioration in the machined surface roughness, but BHN320 suppresses notch wear and achieved double tool life.

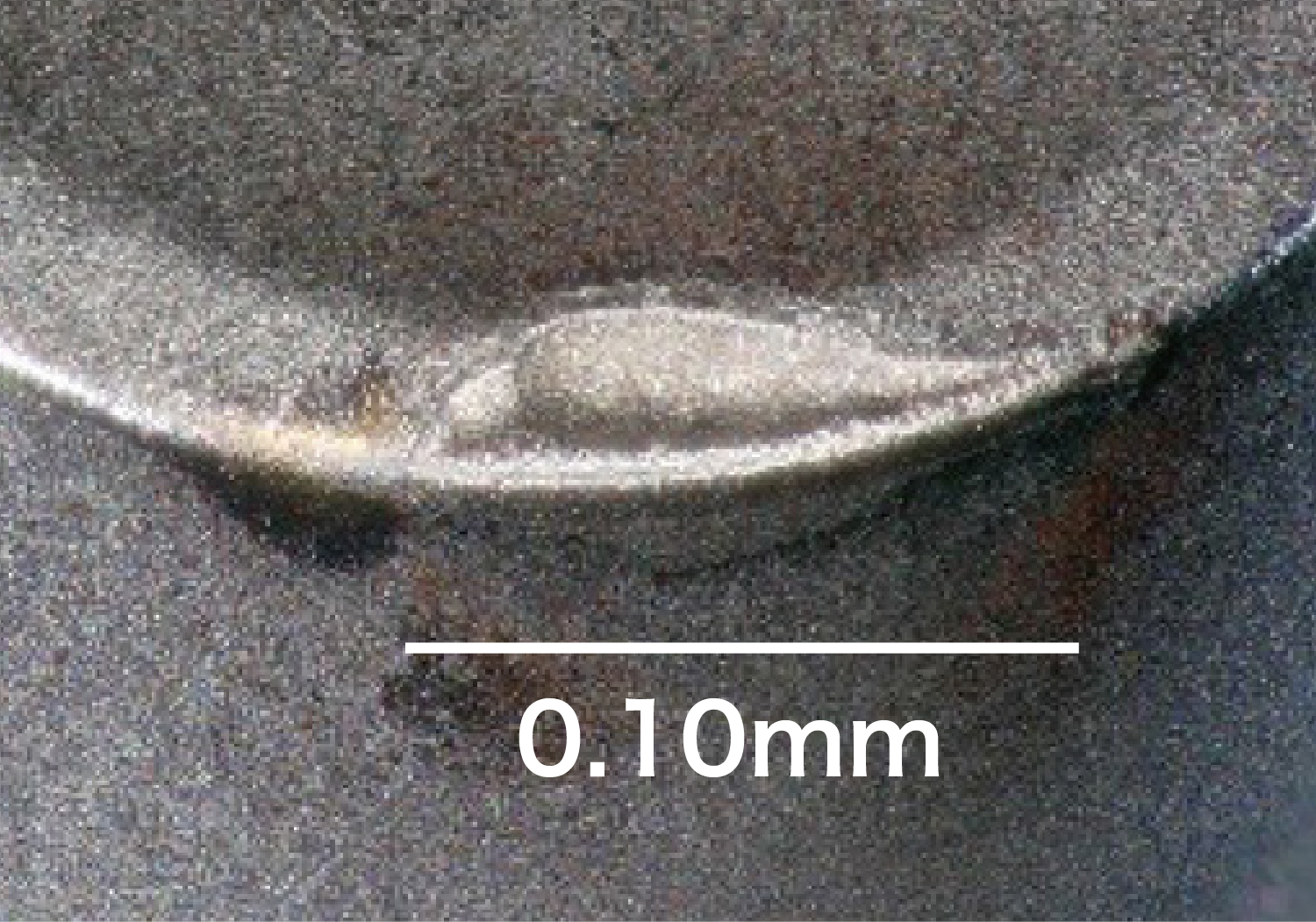

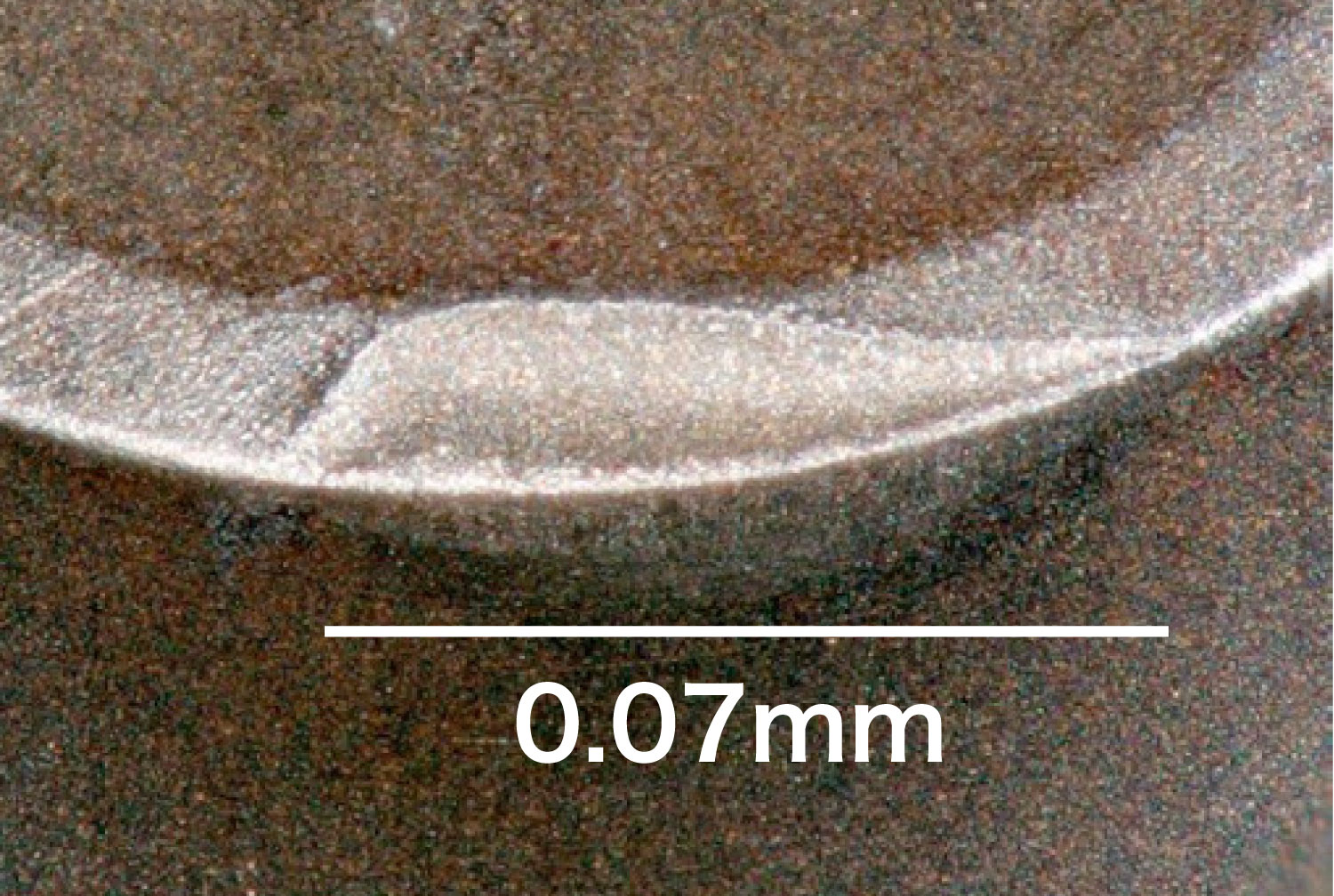

| Automotive parts | ||

|---|---|---|

|  | |

| ||

| ||

| ||

| ||

| ||

| BH340 | 140 pcs / corner | |

| Competitor’s CBN | 100 pcs / corner | |

Conventional CBN frequently suffered from sudden chipping, but BH340 can be stably machined up to a certain point.

For more information about this product, visit our online e-catalog, or download the catalog/product report

Andere empfohlene Produkte