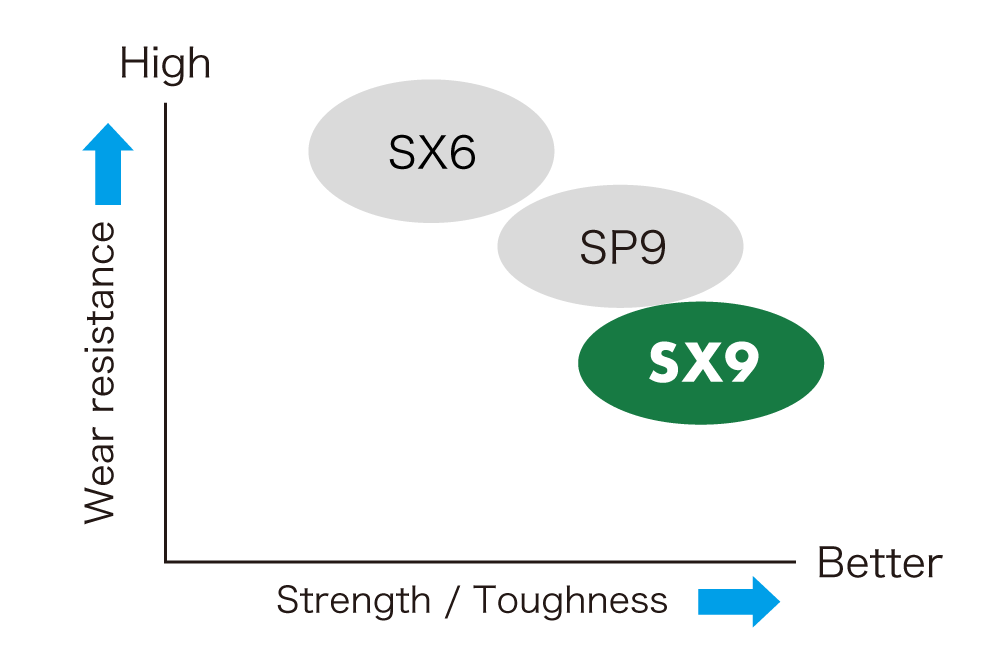

Excellent notch and flank wear resistance when roughing gray cast iron|Sialon ceramic

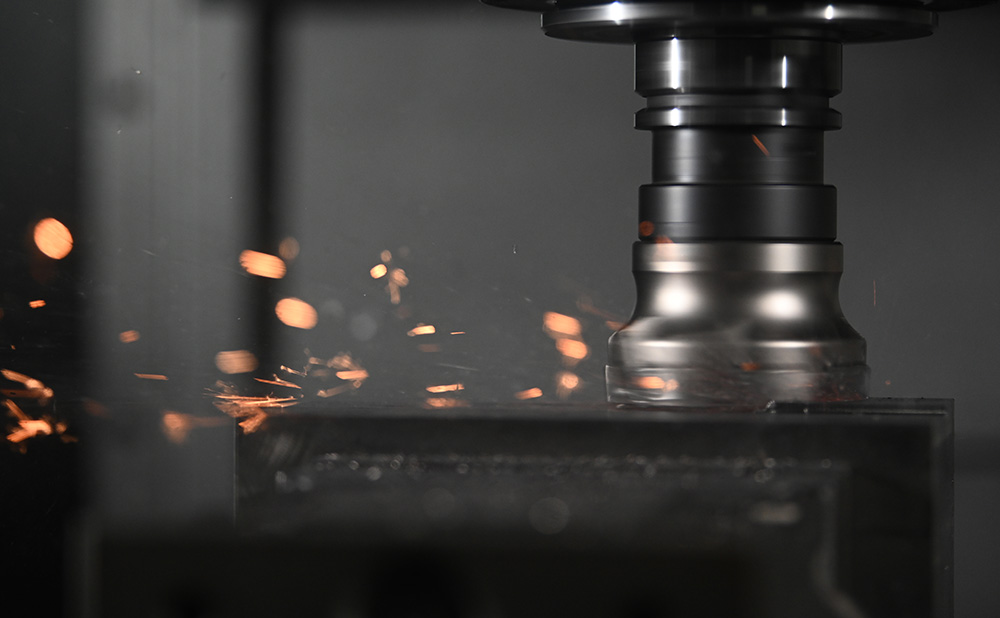

Gray cast iron with scale

Rough Turning / Milling /End milling

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR / IPT) | DOC(mm) DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|

| SX9 | Gray cast iron | Turning | Roughing with scale, Rough to semi-finish machining | 300 – 800 1000 – 2600 | 0.3 – 0.6 .012 – .024 | -3.5 – .140 | DRY |

| Milling | 350 – 700 1200 – 2300 | 0.05 – 0.1 .002 – .004 | – |

| Machine parts | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| SX9 |

850 pcs / corner

|

|

| Competitor’s CVD coated carbide |

300 pcs / corner

|

|

SX9 achieved stable machining results in this interrupted turning operation.

By replacing the CVD coated carbide with ceramic there was a significant reduction in cutting tool costs and an increase in production.

| Brake disc | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| SX9 |

360 pcs / corner

|

|

| Whisker ceramic |

264 pcs / corner

|

|

SX9 machined at the same cutting conditions as the current whisker ceramic and resulted in a reduction in tooling cost for the customer.

For more information about this product, visit our online e-catalog, or download the catalog/product report