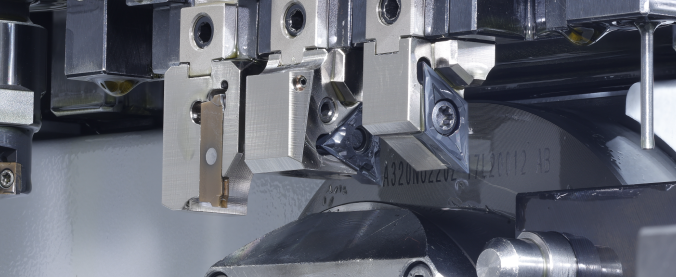

Modular Type | Quick-change tool series for automatic lathes

The user-friendly mechanism ensures precise repeatability, allowing anyone to achieve consistent performance effortlessly.

*The head, shank, and insert corner are identical during measurement.

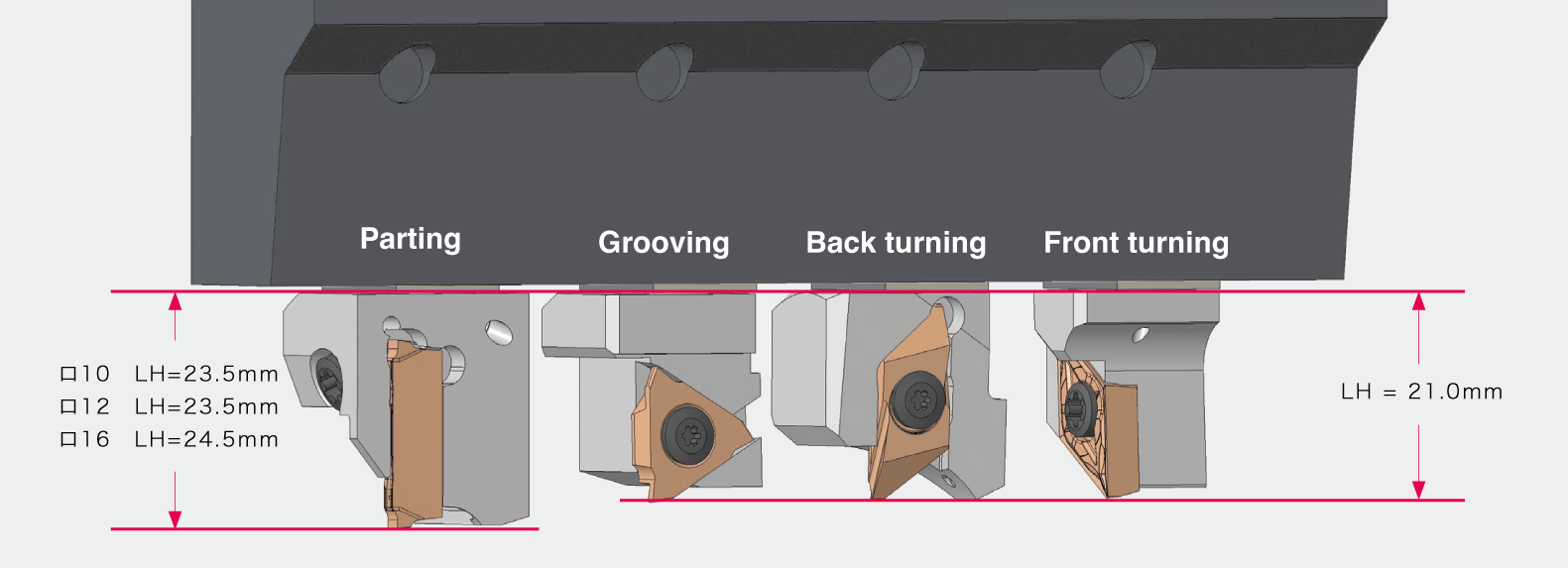

NEW shank size:10×10(QC-10…), 12×12(QC-12…), 16×16(QC-16…)

Front turning / Back turning / Grooving / Threading / Cut off

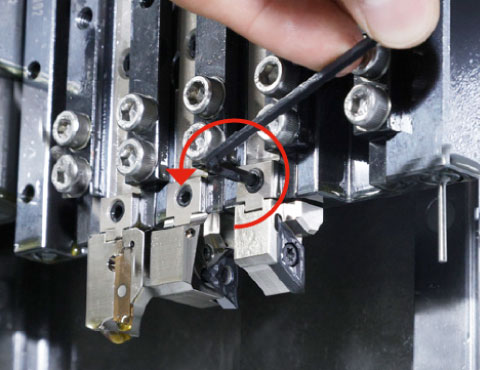

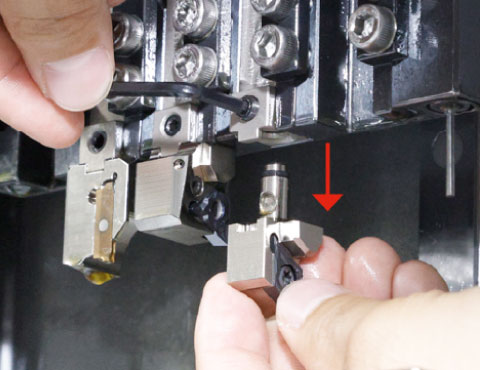

①Loosen the screw.

②The head can be removed without fully detaching the screw.

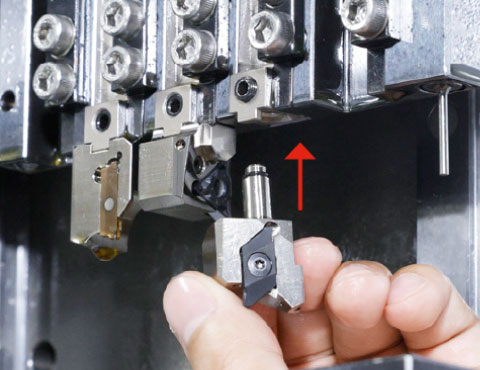

③Insert the head with the replaced insert.

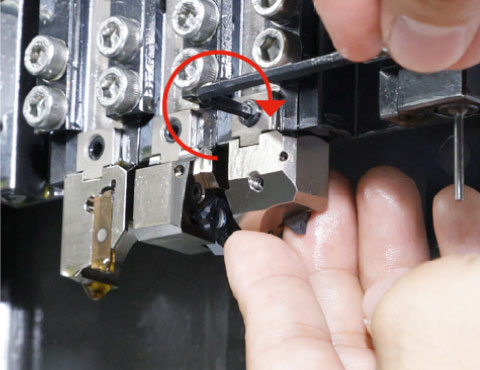

④Tighten the screw on the side while holding the head.

⑤Tool replacement completed.

For more information about this product, visit our online e-catalog, or download the catalog/product report