For thread forming| Swiss CNC lathes

Swiss CNC lathes threading

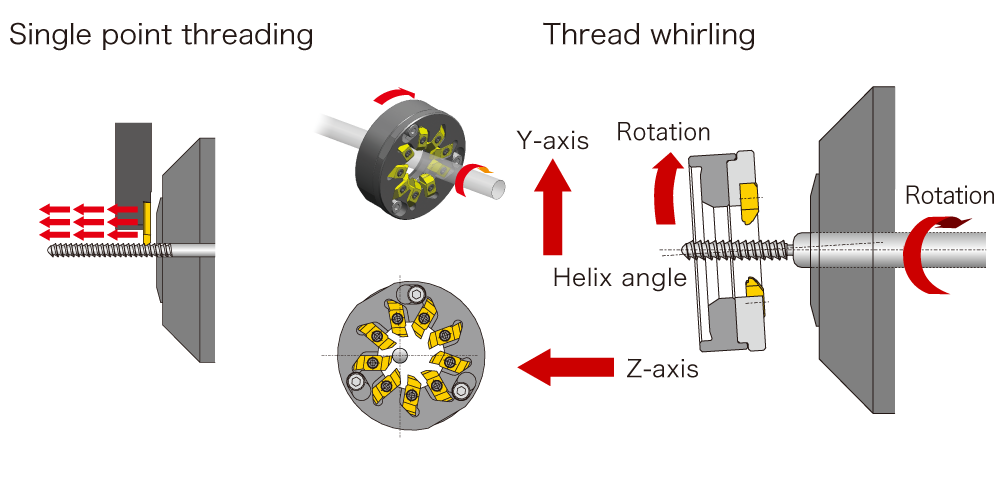

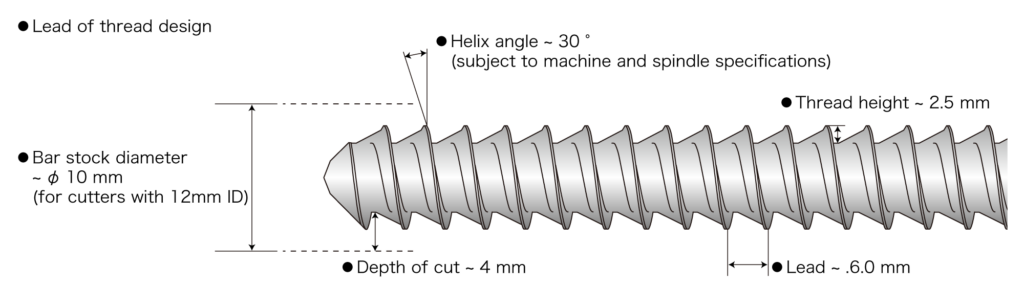

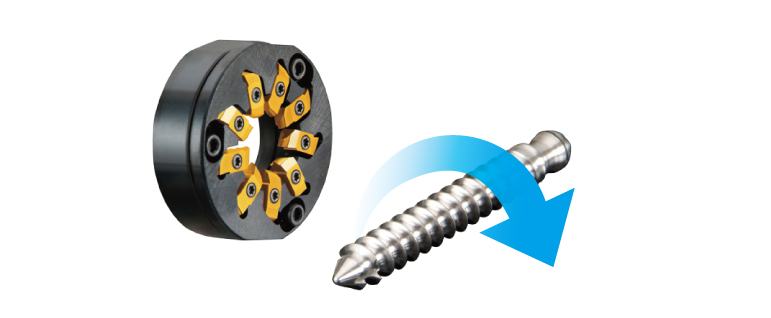

In thread whirling, the whirling head is tilted to a specific helix angle, the cutter is rotated at high speed, the bar stock (c axis) is rotated at a low speed, and the pitch (z axis) is the feed.

The inserts shear the material which enables single pass thread forming.

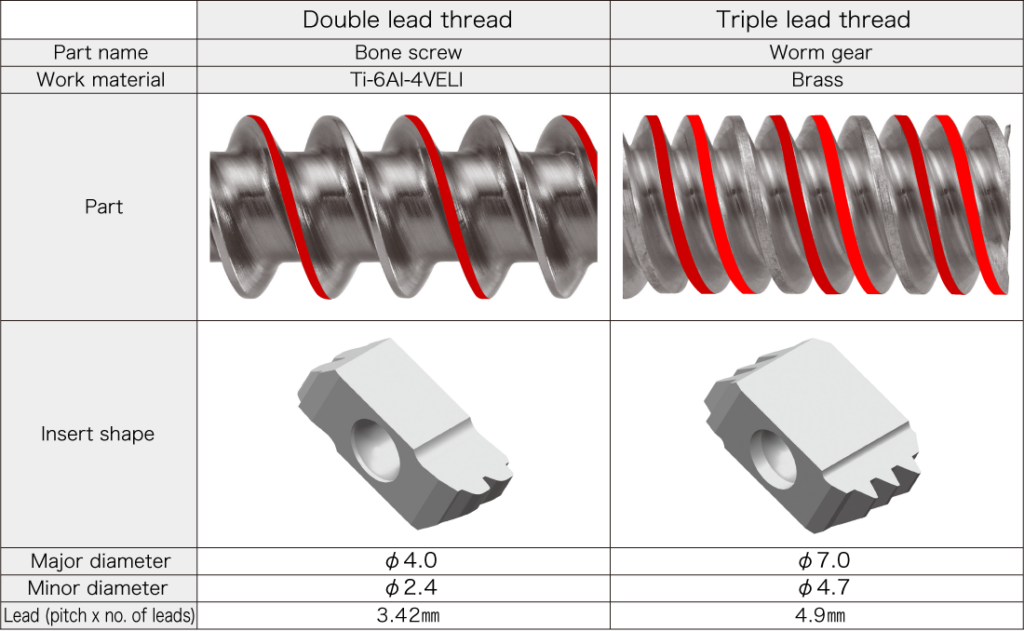

Machining multi-lead tread forms has many process requirements.

So it is important to contact us to discuss: mechanical specifications, spindle specifications, insert specifications, tooling specifications.

|

|

| Left hand Screw | Right hand Screw |

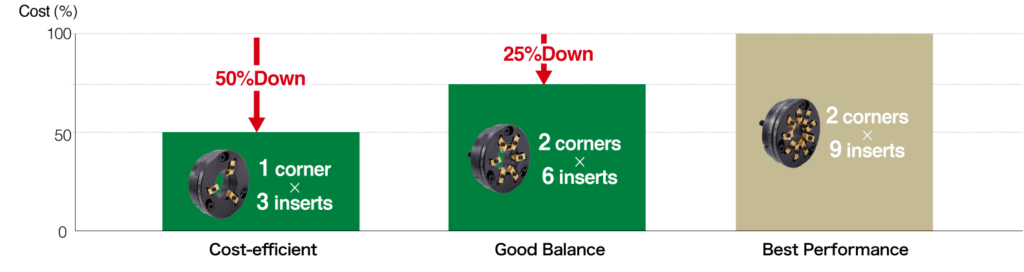

The number of inserts can now be selected according to the balance between machining time and cost.

|

||

|---|---|---|

|

|

|

| 3 inserts | 6 inserts | 9 inserts |

| Emphasis on cost | Balance | Emphasis on machining efficiency |

The number of corners can now be selected according to the number of workpieces produced.

|

|

| 1 corner type | 2 corner type |

| For prototyping and small-lot, high-mix production | For mass production |

| Conditions / No. of teeth | 9 | 6 | 3 | |

|---|---|---|---|---|

| Main spindle | min-1 | 10 – 40 | 10 – 25 | 5 – 12 |

| Whirling cutter | min-1 | 1,500 – 4,000 | ||

| Feed rate | Same as thread lead = pitch | |||

| Bar stock | mm | -⌀10 | -⌀10 | -⌀10 |

| Work Material | Ti-6Al-4V EL / SUS316 / 17-4PH / Titanium / Brass etc. | |||

| Workpiece diameters | Work materials |

|---|---|

| For cutter with ID of ⌀12mm ⌀.472inch | Pure titanium, titanium alloys, SUS316, etc. |

| Worm gear | ||

|---|---|---|

| Work material : | Brass | |

| Bar stock diameter : ⌀7 ⌀.276” | Major diameter : ⌀6 ⌀.236” | Minor diameter : ⌀4 ⌀.157” |

| Number of start : 2 | Helix angle : 10.1° | Hand of thread: left |

| Main spindle speed : | 30min -1 | |

| Whirling cutter speed : | 3,200min -1 | |

| Lead = Feed : | 2.8mm/rev .110 IPR | |

| NTK Thread Whirling 9 teeth | 25 seconds | |

| Single point | 50 seconds | |

By replacing the single point threading tools with a thread whirling system the machine time for threading operation is greatly reduced and the total cycle time for the part is cut by 50%.

| Pin | ||

|---|---|---|

| Work material : | Hastelloy | |

| Bar stock diameter : ⌀3 ⌀.118” | Major diameter : ⌀1.5 ⌀.059” | Minor diameter : ⌀1.1 ⌀.043” |

| Number of leads : 1 | Helix angle : 4.3° | Hand of thread: right |

| Main spindle speed : | 20min -1 | |

| Whirling cutter speed : | 2,250min -1 | |

| Lead = Feed : | 0.3mm/rev .012 IPR | |

| NTK Thread Whirling 9 teeth | 600 pcs / corner | |

| Single point | 100 pcs / corner | |

By replacing the single point threading tools the threading system significantly improved tool life machining the difficult to cut Hastelloy material.

| Bone screw | ||

|---|---|---|

| Work material : | SUS316 | |

| Bar stock diameter : ⌀8 ⌀.314” | Major diameter : ⌀3.45 ⌀.135” | Minor diameter : ⌀2.67 ⌀.105” |

| Number of leads : 2 | Helix angle : 7.5° | Hand of thread: right |

| Main spindle speed : | 23min -1 | |

| Whirling cutter speed : | 2,000min -1 | |

| Lead = Feed : | 1.24mm/rev .048 IPR | |

| NTK Thread Whirling 9 teeth | 2,600 pcs / corner | |

| Competitor’s Thread Whirling 6 teeth | 1,000 pcs / corner | |

NTK thread whirling inserts achieved 2.6 x longer tool life compared to the competitor’s thread whirling inserts.

| Bone screw | ||

|---|---|---|

| Work material : | SUS316 | |

| Bar stock diameter : ⌀6.35 ⌀.250” | Major diameter : ⌀3.23 ⌀.127” | Minor diameter : ⌀2.2 ⌀.086” |

| Number of leads : 1 | Helix angle : 8.5° | Hand of thread: right |

| Main spindle speed : | 15min -1 | |

| Whirling cutter speed : | 2,250min -1 | |

| Lead = Feed : | 1.27mm/rev .005 IPR | |

| NTK Thread Whirling 9 teeth | 1,200 pcs / corner | |

| Competitor’s Thread Whirling 12 teeth | 1,000 pcs / corner | |

| Competitor’s Thread Whirling 3 teeth | 400 pcs / corner | |

NTK whirling inserts achieved 1.2 to 3 times longer tool life compared to the competition.

For more information about this product, visit our online e-catalog, or download the catalog/product report