For continuous machining | NTK CeramiX

For continuous machining | NTK CeramiX

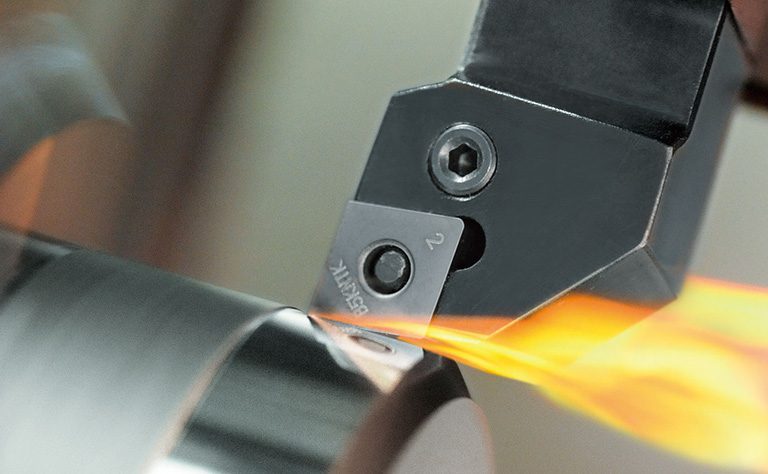

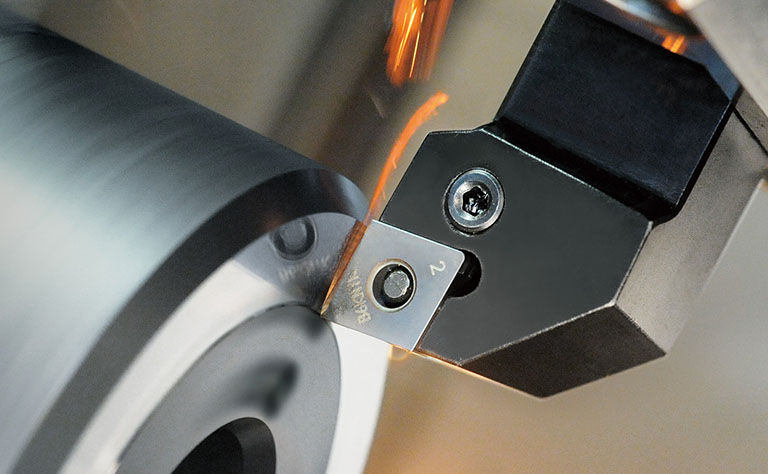

The ultimate ceramic grade for finishing hardened materials -" NTK CeramiX "

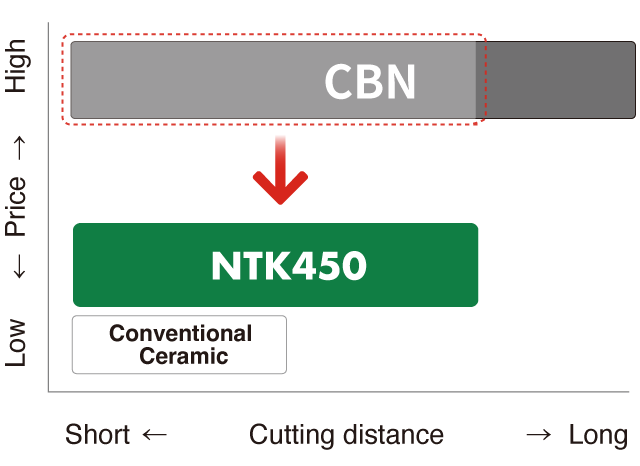

Wins against CBN with the combination of performance and price

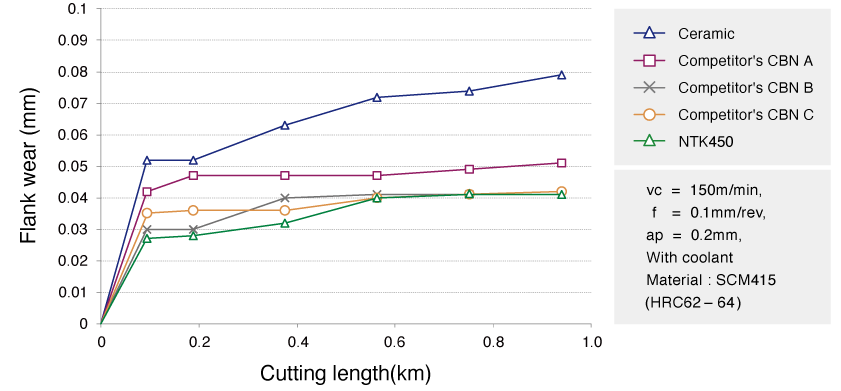

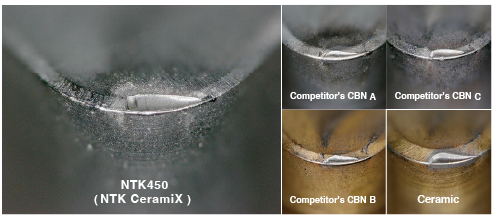

Matches the excellent wear resistant characteristics of CBN

Significant cost savings compared to CBN

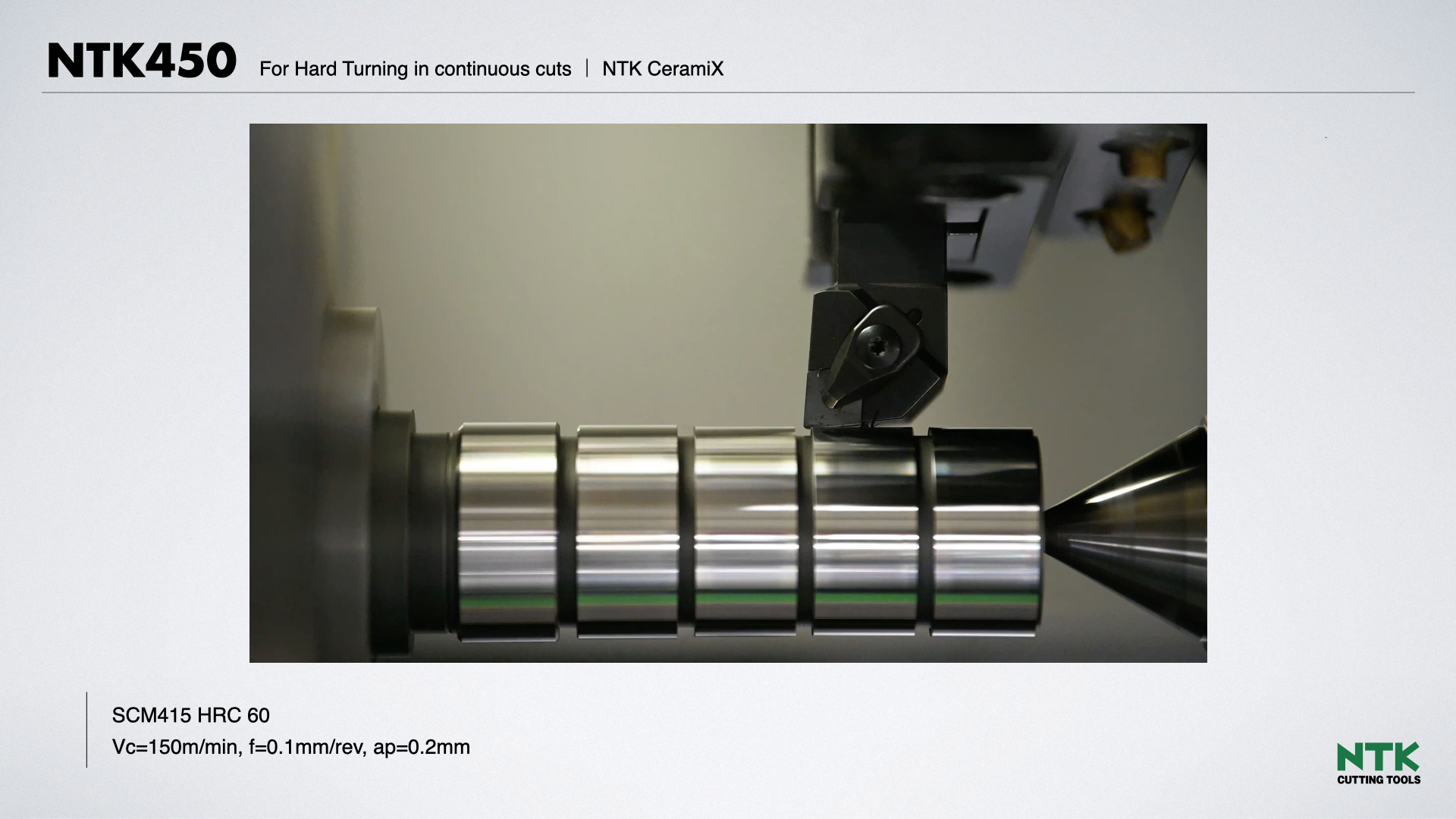

Product video

Features

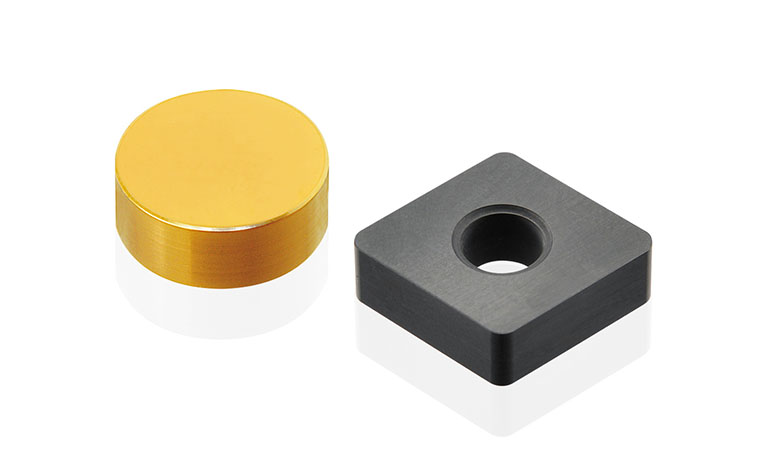

- NTK CeramiX is an advanced ceramic material achieving the performance to compete with CBN

- New TiAlN coating offers excellent wear resistance for hard turning

- In continuous machining materials with a hardness of 55 to 65 HRC, NTK450 matches the performance of CBN with the benefit of cost reductions

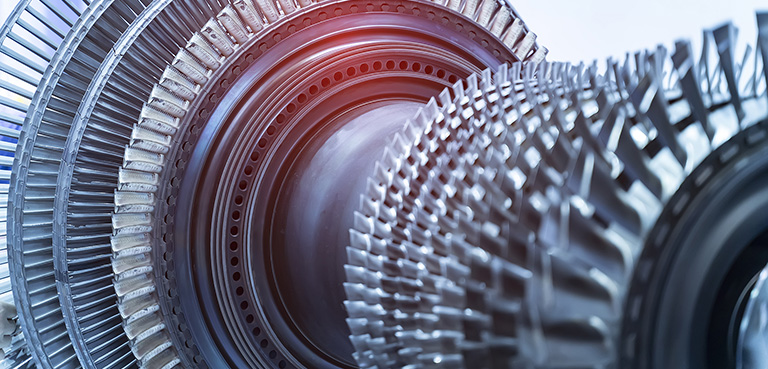

Tooling application

Hardened materialContinuous machining HRC55-65

Price and Performance comparison

Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Machining | Cutting speed (m/min) | Feed (mm/rev) | DOC (mm) | DRY | WET |

|---|---|---|---|---|---|---|---|---|

| NTK450 | Hardened material (HRC55-65) |

Turning | Finishing | 100 - 200 | 0.08 - 0.15 | 0.1 - 0.5 | ● | ● |

| The same conditions as current CBN | ||||||||

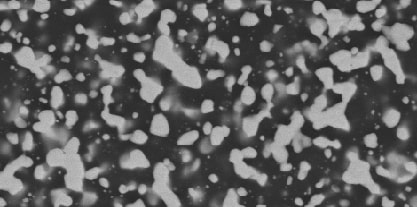

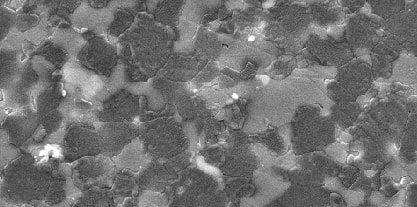

Material characteristic

Scroll the table →

| Grade | Coating | Density (g/cm3) | Bending Strength (MPa) | Hardness (Hv) | Fracture Toughness (MPa・√m) | Structure |

|---|---|---|---|---|---|---|

| NTK450 | TiAlN Specialized for NTK450 | 7.5 | 1200 | 2290 | 5.7 |  |

| Conventional Ceramic | TiN | 4.6 | 1100 | 2060 | 4.3 |  |

Wear comparison vs. CBN

Case study

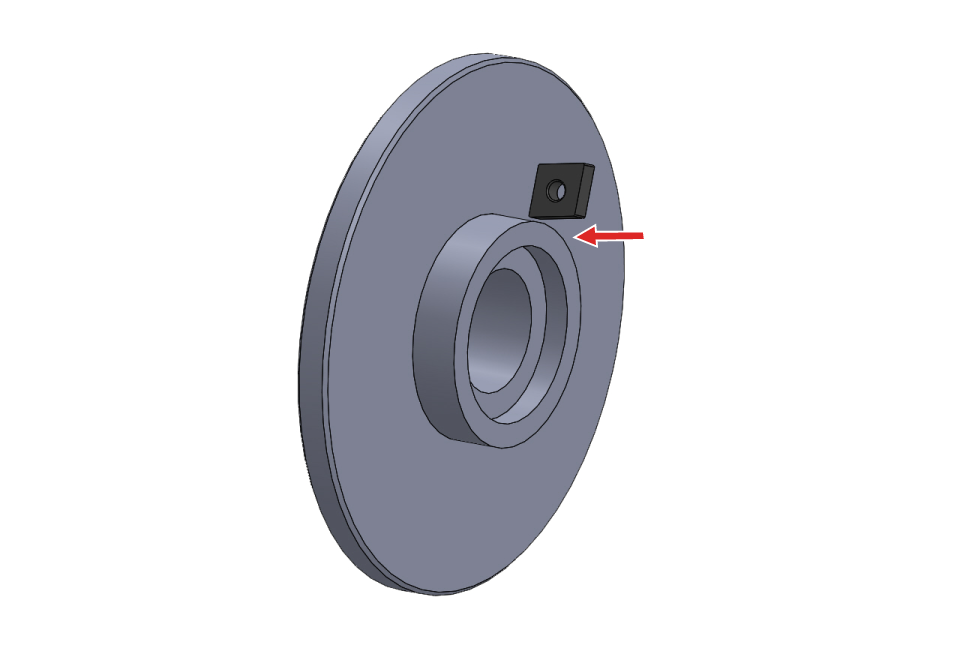

| Industrial robot component | |

|---|---|

|

part diameter : Φ60 part diameter : Φ60 |

|

|

|

|

|

|

|

|

| NTK450 TNGA160404 | 30 pcs / corner |

| Competitor's coated CBN | 15pcs / corner |

NTK450 achieved double the tool life vs. the competitor's coated CBN insert.

Switching to CeramiX will result in a 70% reduction in tool cost per year.

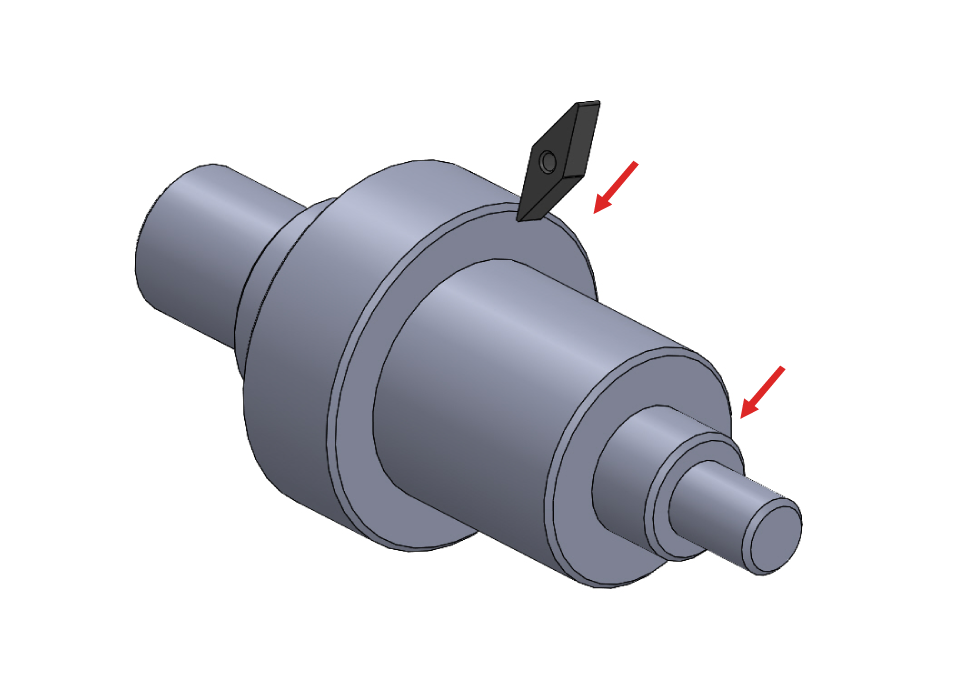

| Gear | |

|---|---|

|

part diameter : Φ150 part diameter : Φ150 |

|

|

|

|

|

|

|

|

| NTK450 CNGA120404 | 200 pcs / corner |

| Competitor's coated CBN | 200 pcs / corner |

NTK450 matched the tool life of the competitor's coated CBN.

The result is a 50% reduction in insert costs for the customer.

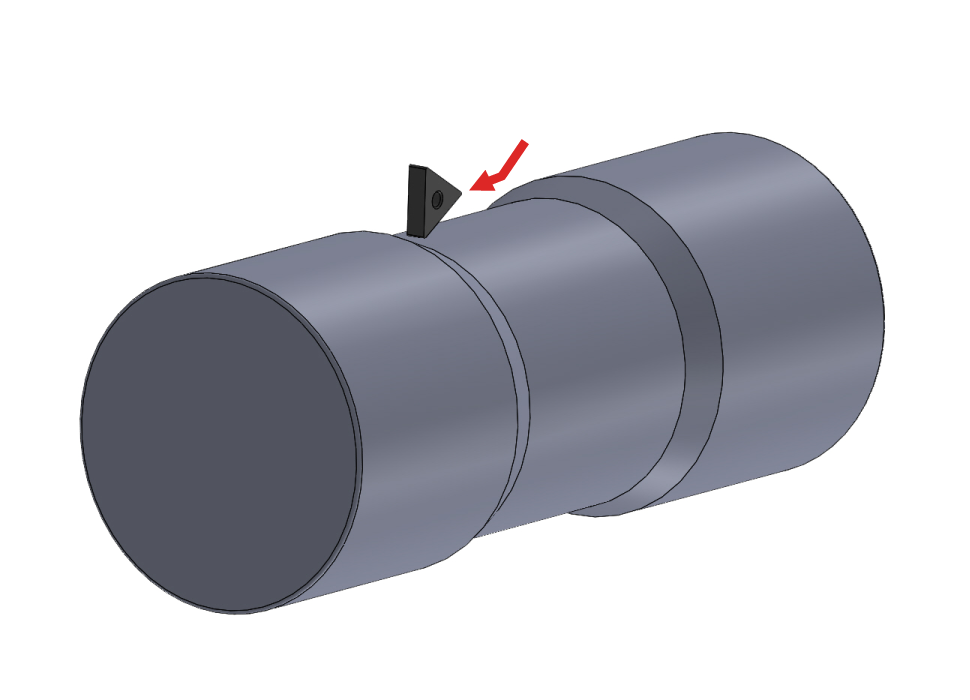

| Holder part | |

|---|---|

|

part diameter : Φ60 part diameter : Φ60 |

|

|

|

|

|

|

|

|

| NTK450 VNGA160404 | 20 pcs / corner |

| Competitor's CBN | 20 pcs / corner |

NTK450 matched the tool life of the competitor's coated CBN.

The result is a 30% reduction in insert costs with NTK450.

| Industrial part | |

|---|---|

|

part diameter : Φ250 part diameter : Φ250 |

|

|

|

|

|

|

|

|

| NTK450 TNGA160404 | 16pcs / corner |

| Competitor's coated CBN | 20 pcs / corner |

NTK450 achieved 80% of the tool life compared to competitor's coated CBN with the same cutting conditions.

Replacing the CBN with NTK450 will result in a 10% tool cost reduction for the customer.

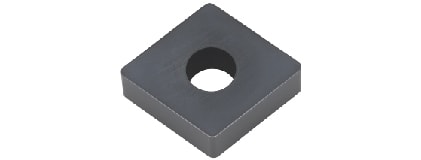

Tool lineup

Scroll the table →

| Unit : 1pc/case * | Unit : 10pcs/case * | ||||||||||||

| Geometry | EDP | Item number | EDP | Item number | Corner R | Grade | Dimensions (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NTK450 | IC | Thickness | Edge preparation | ||||||||||

|

5106125 | CNGA | 120404 | X03 | 5109186 | CNGA | 120404 | X03-10 | 0.4 | ● | 12.7 | 4.76 | 0.1×15° + Honed edge |

| 5106117 | 120408 | X03 | 5109194 | 120408 | X03-10 | 0.8 | ● | ||||||

| 5106091 | 120412 | X03 | 5109202 | 120412 | X03-10 | 1.2 | ● | ||||||

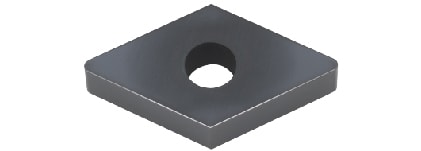

|

5106083 | DNGA | 150404 | X03 | 5109236 | DNGA | 150404 | X03-10 | 0.4 | ● | |||

| 5106075 | 150408 | X03 | 5109301 | 150408 | X03-10 | 0.8 | ● | ||||||

| 5106042 | 150412 | X03 | 5109327 | 150412 | X03-10 | 1.2 | ● | ||||||

|

5106034 | TNGA | 160404 | X03 | 5109343 | TNGA | 160404 | X03-10 | 0.4 | ● | 9.525 | ||

| 5106026 | 160408 | X03 | 5109392 | 160408 | X03-10 | 0.8 | ● | ||||||

| 5106018 | 160412 | X03 | 5109418 | 160412 | X03-10 | 1.2 | ● | ||||||

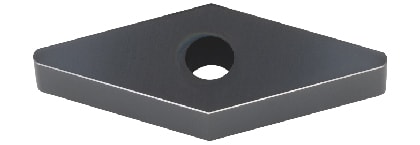

|

5106000 | VNGA | 160404 | X03 | 5109426 | VNGA | 160404 | X03-10 | 0.4 | ● | |||

| 5105994 | 160408 | X03 | 5109434 | 160408 | X03-10 | 0.8 | ● | ||||||

| 5105986 | 160412 | X03 | 5109442 | 160412 | X03-10 | 1.2 | ● | ||||||

* Please order Qty. you need in either item number. Insert case is the only difference.

Other recommended products

-

ZC7/HC4For continuous machining | Ceramic for machining materials 30 - 70 HRC

Significant cost savings for high hardness materials

-

B5K/B52For continuous-light interruption machining | CBN for machining hardened material

High performance, low cost, versatile CBN

-

B6K/B36For light to medium interrupted machining | CBN for machining hardened material

High performance, low cost CBN

-

B40For heavy interrupted machining | CBN for machining hardened material

High performance, low cost CBN

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch