Roughing to finishing of ductile cast iron & gray cast iron| Coated Silicon Nitride Ceramic

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR / IPT) | DOC(mm) DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|

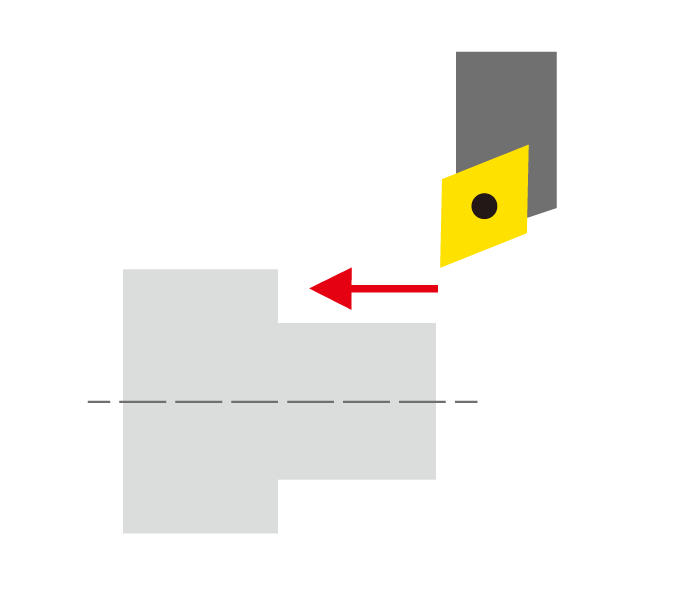

| SP9 | Gray cast iron | Turning | Turning Roughing ~ Finishing | 350 – 800 1200 – 2700 | 0.3 – 0.6 .012 – .024 | -3.5 – .140 | DRY |

| Ductile cast iron | 250 – 550 800 – 1800 | 0.15 – 0.4 .006 – .016 | -3.0 – .120 | DRY | |||

| Gray cast iron | Milling | Milling Roughing ~ Semi-Finishing | 350 – 700 1200 – 2500 | 0.07 – 0.25 .003 – .010 | -6.0 – .240 | DRY | |

| Ductile cast iron | 400 – 800 1300 – 2700 |

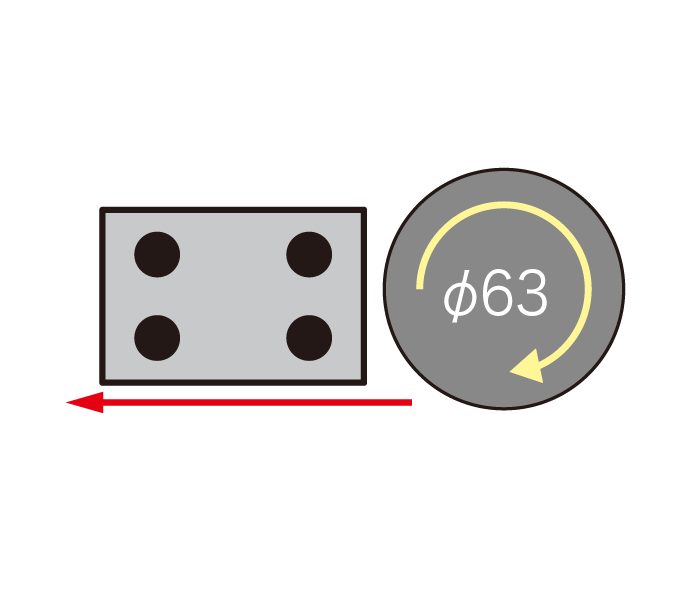

| Differential case | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| SP9 |

C/T 30 seconds / part

|

|

| Competitor’s CVD coated carbide |

C/T 60 seconds / part

|

|

SP9 machined at a higher speed than the competitor’s CVD coated carbide and reduced cutting time by 50%.

| Auto parts | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

|

||

| SP9 |

1,300 pcs/ corner

|

|

| Competitor’s silicon nitride ceramic |

800 pcs/ corner

|

|

SP9 achieved 1.6 X higher tool life than the competitor’s ceramic.

For more information about this product, visit our online e-catalog, or download the catalog/product report