Back turning | Swiss CNC Lathes

Swiss CNC lathe back turning

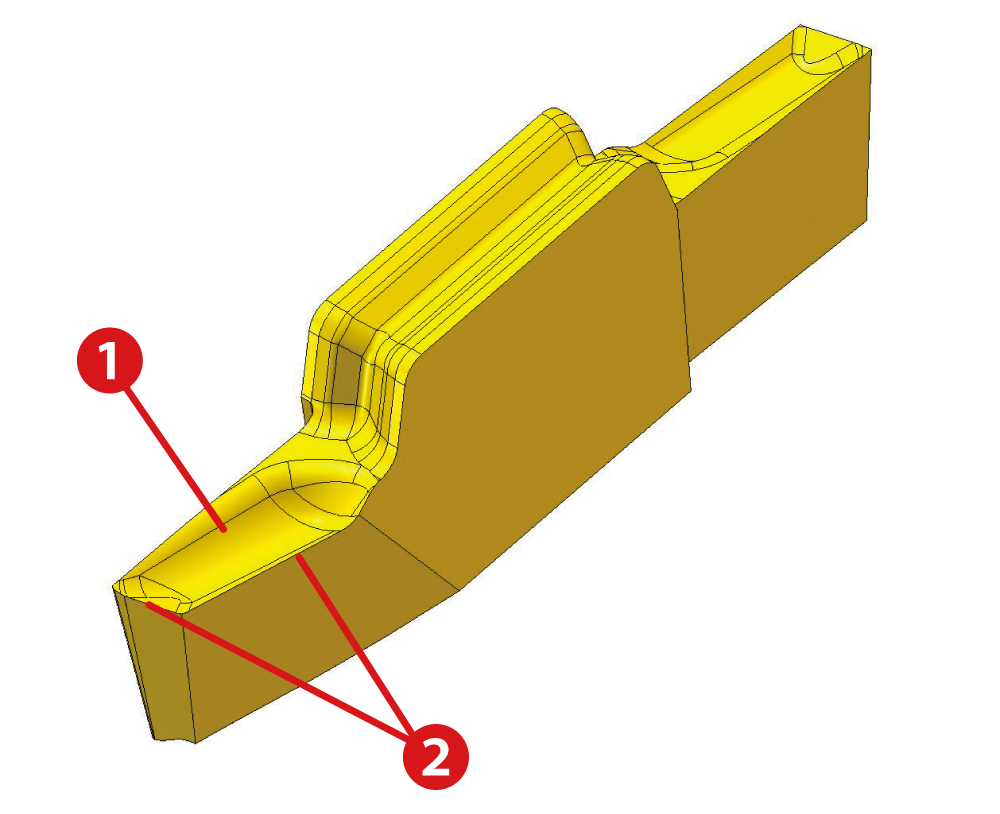

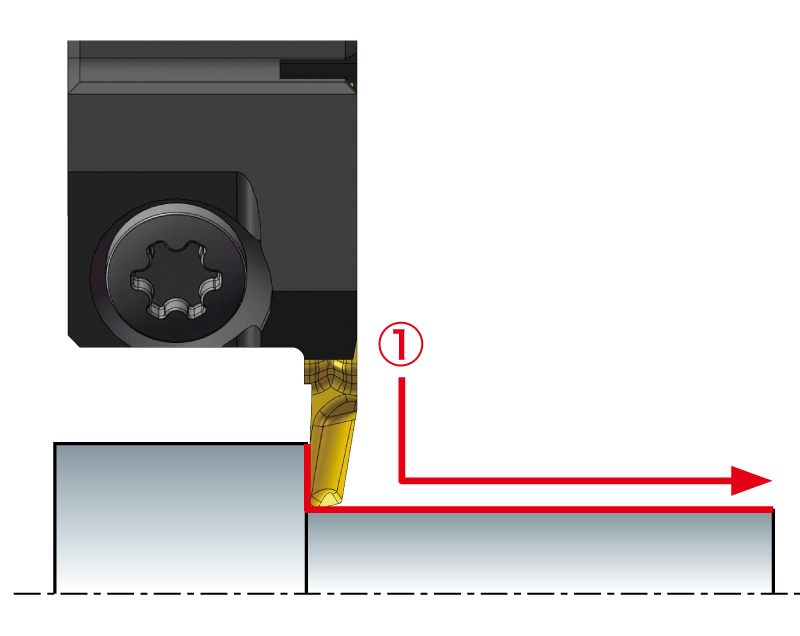

➀ Excellent surface with good chipcontrol

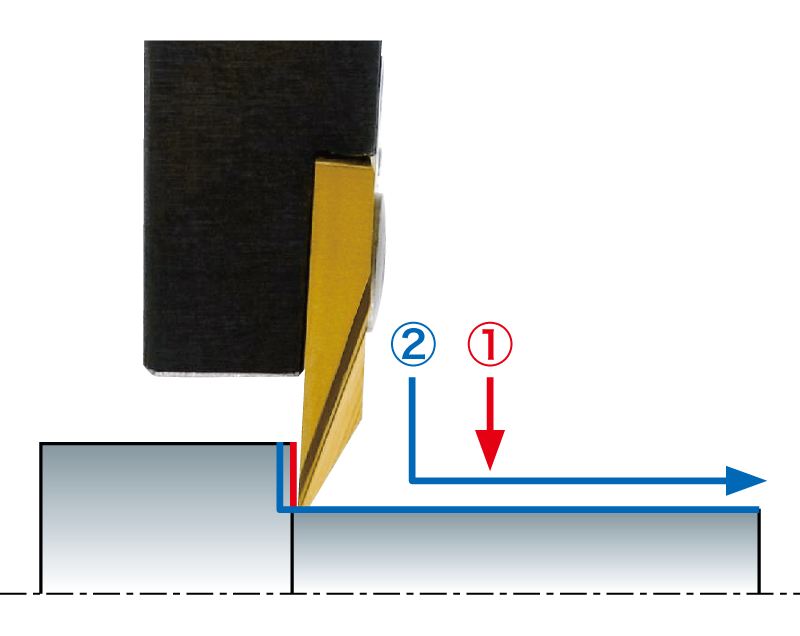

➁ Improved surface finish thanks to wiper flat on cutting edge.

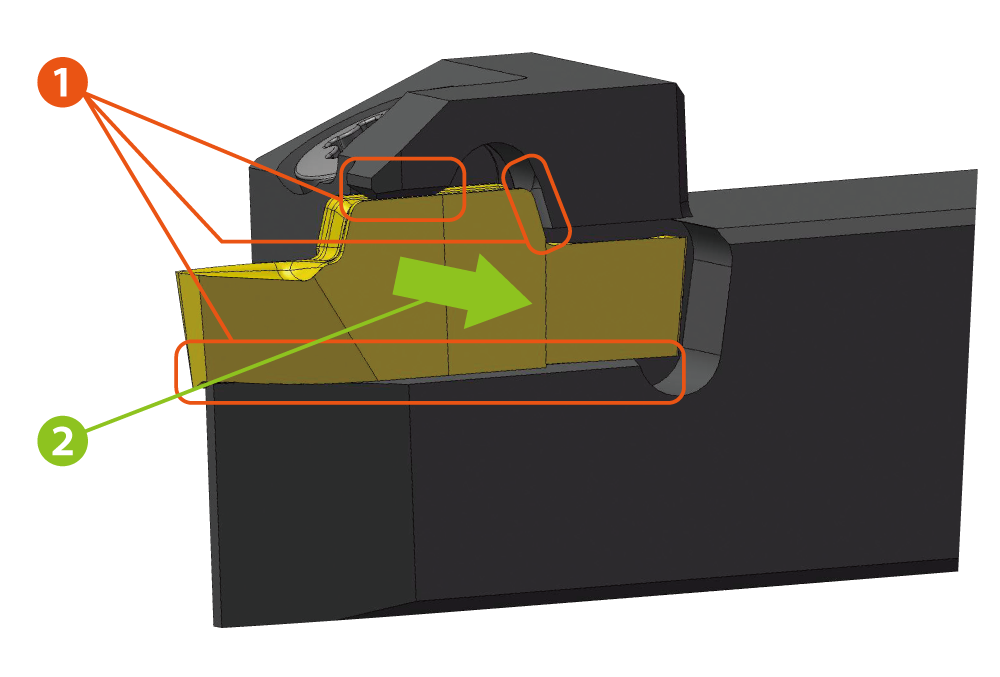

➀ Stable clamping force from three face contact with V-bottom

➁ Utilizes tool pressure to increase clamping force.

BACK DUO

BACK DUO is able to machine by guide bush for high accuracy back turning.

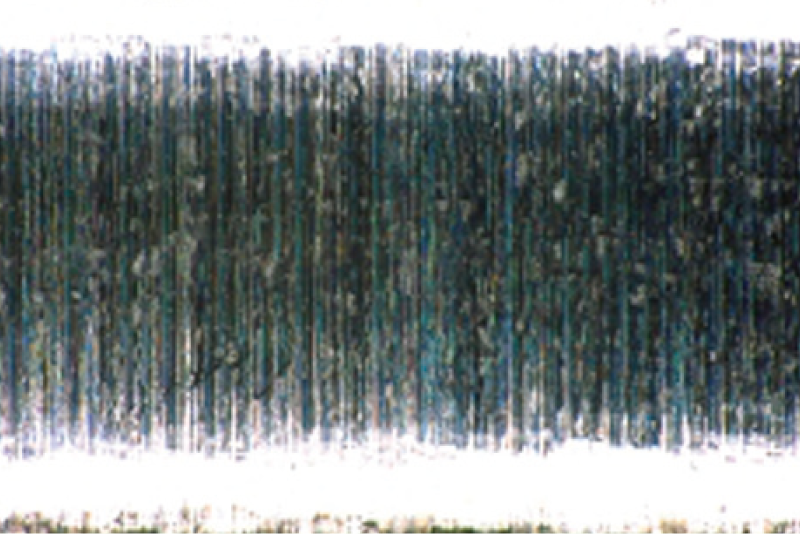

Conventional

BACK DUO

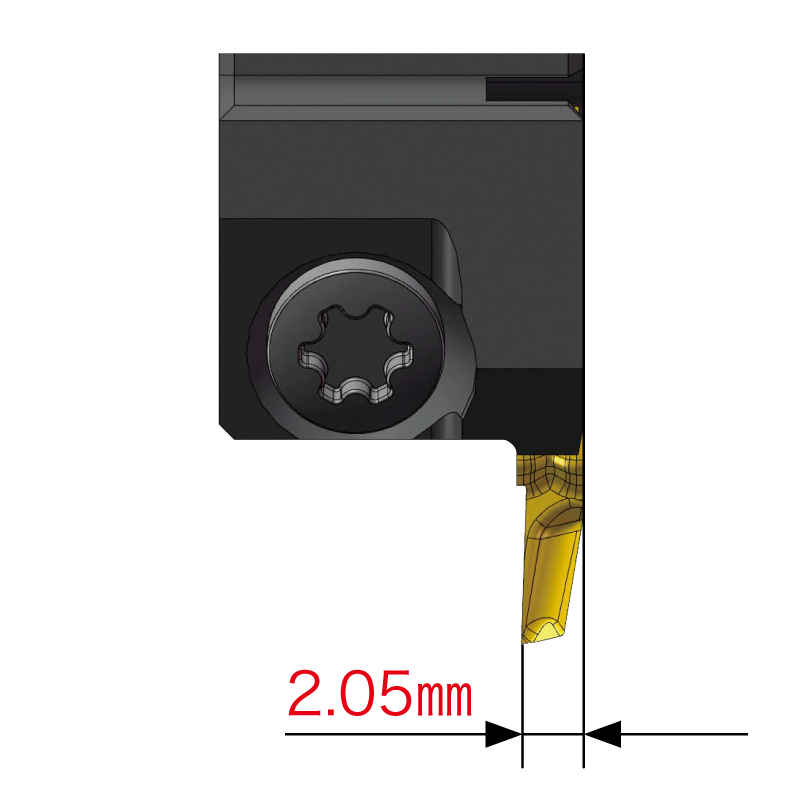

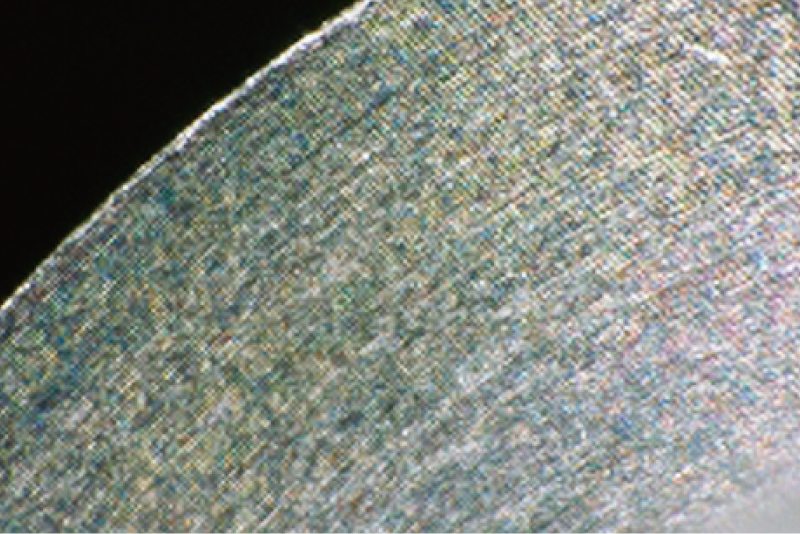

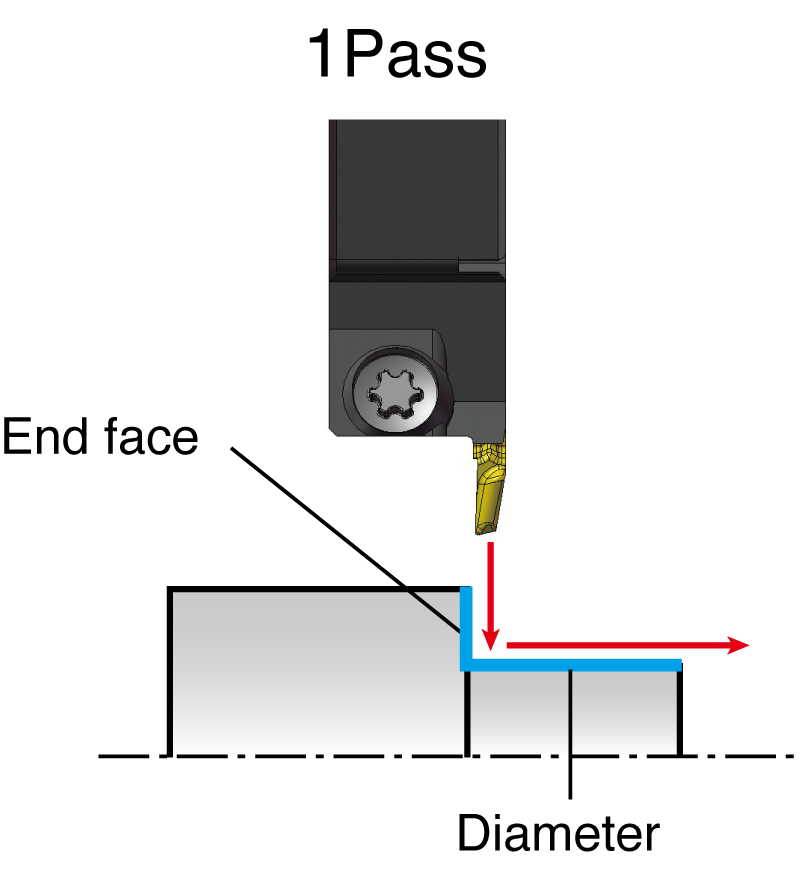

Excellent surface by 1Pass

Conventional

Conventional machining requires a second finishing cut on the end face.

End face

Excellent surface

Diameter

Ra:0.90μm / Rz:4.11μm

End face

Rough surface

Diameter

Ra:2.16μm / Rz:10.28μm

Work material:SUS304

Holder:TBDPR12

Insert:TM4 TBDP2201MR

Cutting condition: Vc=

80m/min

.260 SFM

(x)=

0.02mm/rev

.001 IPR

(z)=

0.08mm/rev

.003 IPR

ap=

3.0mm

.120 inches

WET

| ISO | Work material | Grade | vc (m/min) (SFM) | ap (mm) (inch) | X Direction f (mm/rev) (IPR) |

Z Direction f (mm/rev) (IPR) |

|---|---|---|---|---|---|---|

| Carbon steel Alloy steel |

DM4 | 40 – 150 130 – 500 | 0.5 – 3.0 .020 – .120 | 0.01 – 0.04 .0004 – .0016 | 0.02 – 0.08 .0008 – .0031 | |

| TM4 | 40 – 90 130 – 300 | |||||

| QM3 | 40 – 150 130 – 500 | |||||

| Difficult-to-cut Free-cutting stainless steel |

ST4 | 40 – 150 130 – 500 | 0.5 – 3.0 .020 – .120 | 0.01 – 0.04 .0004 – .0016 | 0.02 – 0.08 .0008 – .0031 | |

| DM4 | 40 – 100 130 – 330 | |||||

| TM4 | 40 – 90 130 – 300 | |||||

| QM3 | 30 – 90 100 – 300 | |||||

| HRSA Co-Cr alloy |

DM4 | 20 – 80 70 – 260 | 0.5 – 2.0 .020 – .080 | 0.01 – 0.03 .0004 – .0012 | 0.02 – 0.08 .0008 – .0031 |

For more information about this product, visit our online e-catalog, or download the catalog/product report