For front turning operations | Swiss CNC Lathes

Swiss CNC Lathe front turning operations

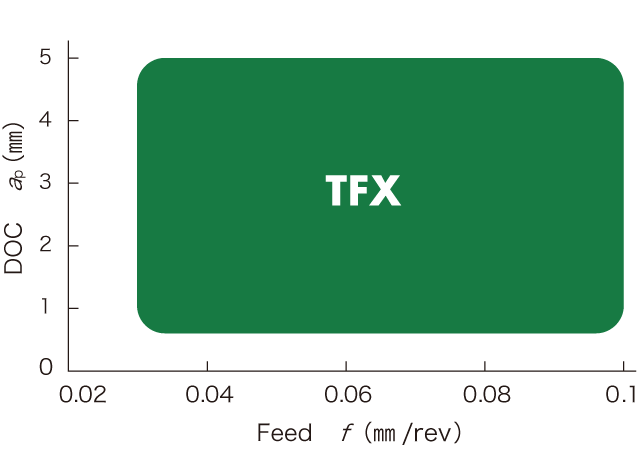

| Coated grade | Material | Operation type | Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/rev) Feed (IPR) | DOC (mm) DOC (inch) |

|---|---|---|---|---|---|

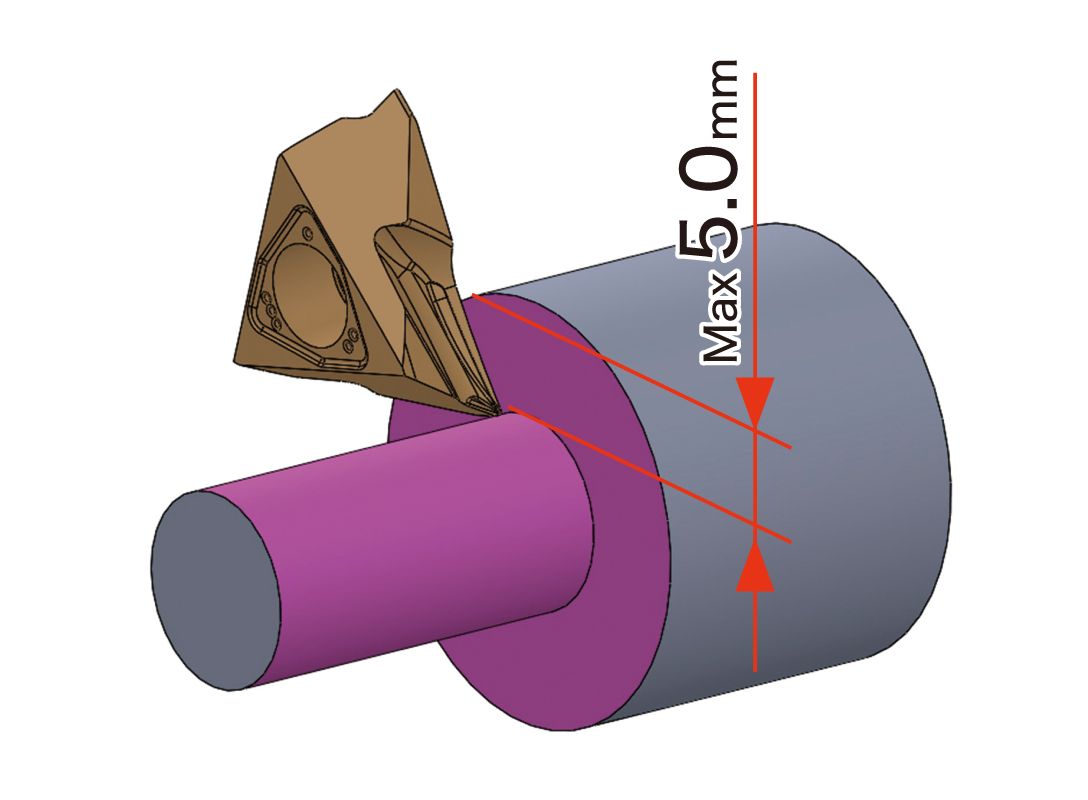

| ST4 | Stainless | OD Turning continuous | 50 – 120 150 – 400 | 0.03 – 0.1 .001 – .004 | 0.5 – 5.0 .020 – .197 |

| DM4 | Difficult-to-cut material / titanium alloy Alloy steel / carbon steel / hardened material Non-ferrous / aluminum / plastic / general purpose |

Note: Initial dimensional adjustments may be required depending on the machining condition.

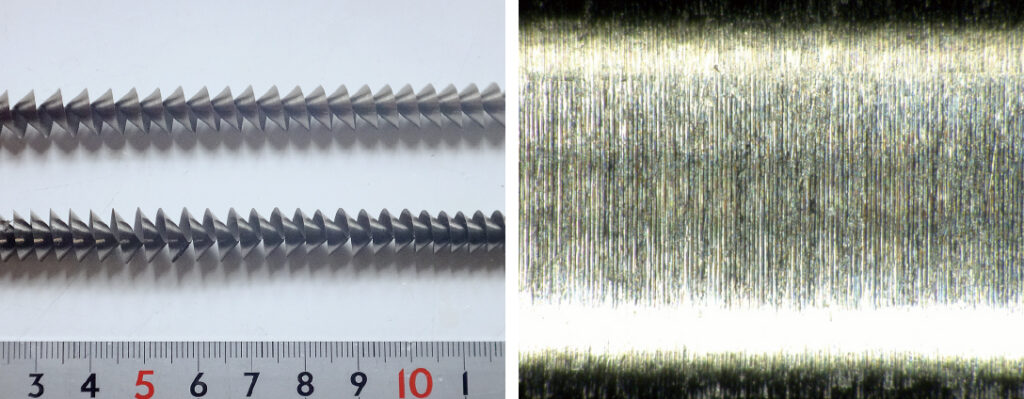

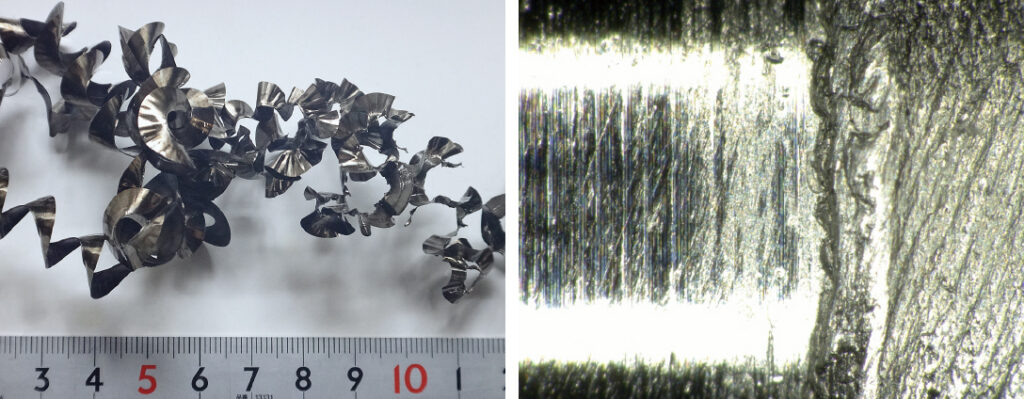

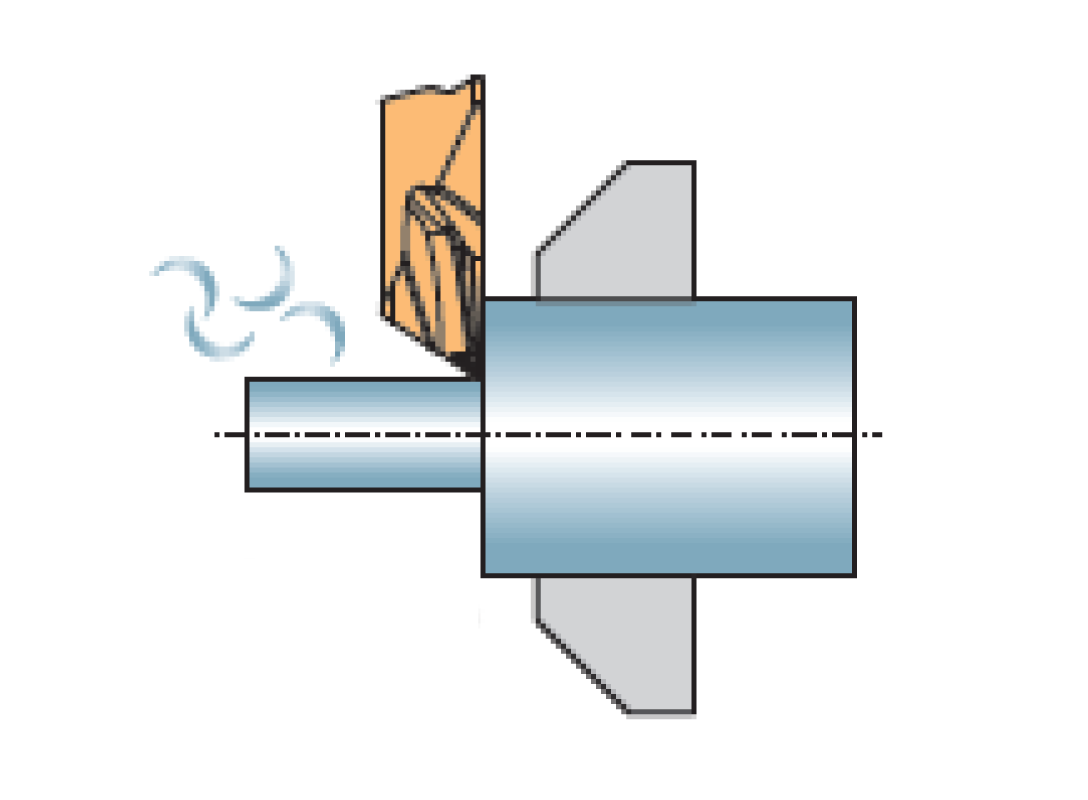

High rigidity and chip control ensures consistently superior surface finishes

Lack of chip control leads to a poor machined surface finish

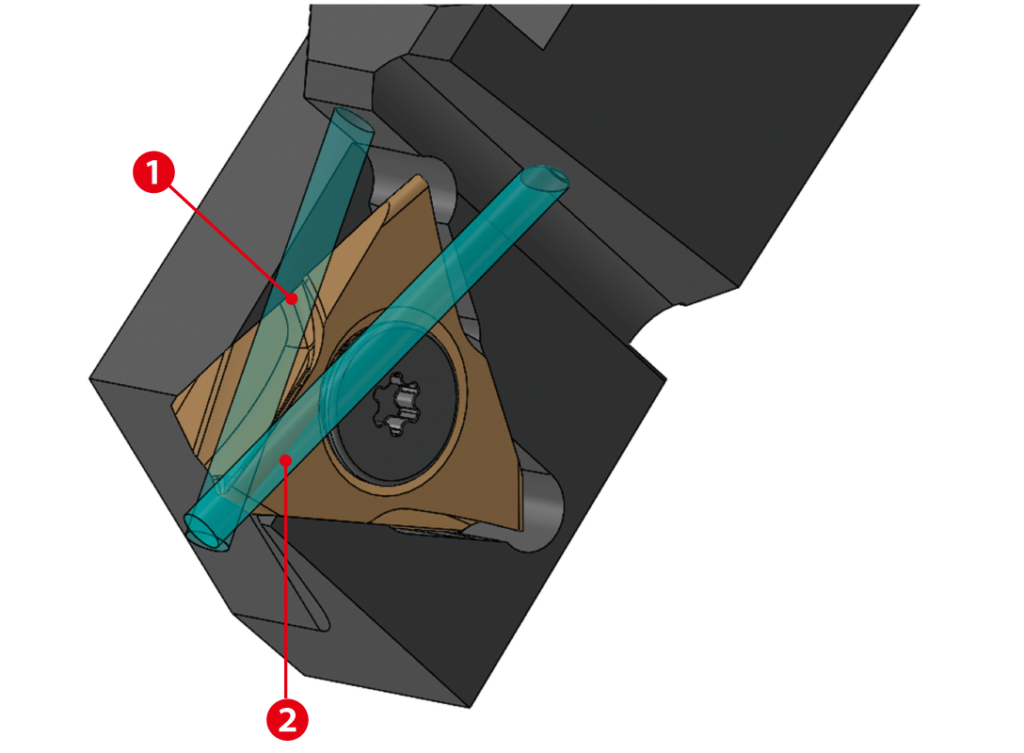

Coolant through holders are available for TFX inserts to provide further machining stability

① Coolant stream directed to evacuate chips

② Coolant stream improves insert tool life

| Shaft | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| The Front Max |

180 pcs / corner

|

| Competitor’s product |

50 pcs / corner |

| Electronic component | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| ST4+ The Front Max |

160 pcs / corner

|

| CCGT09 Type (PVD coated carbide) |

80 pcs / corner

|

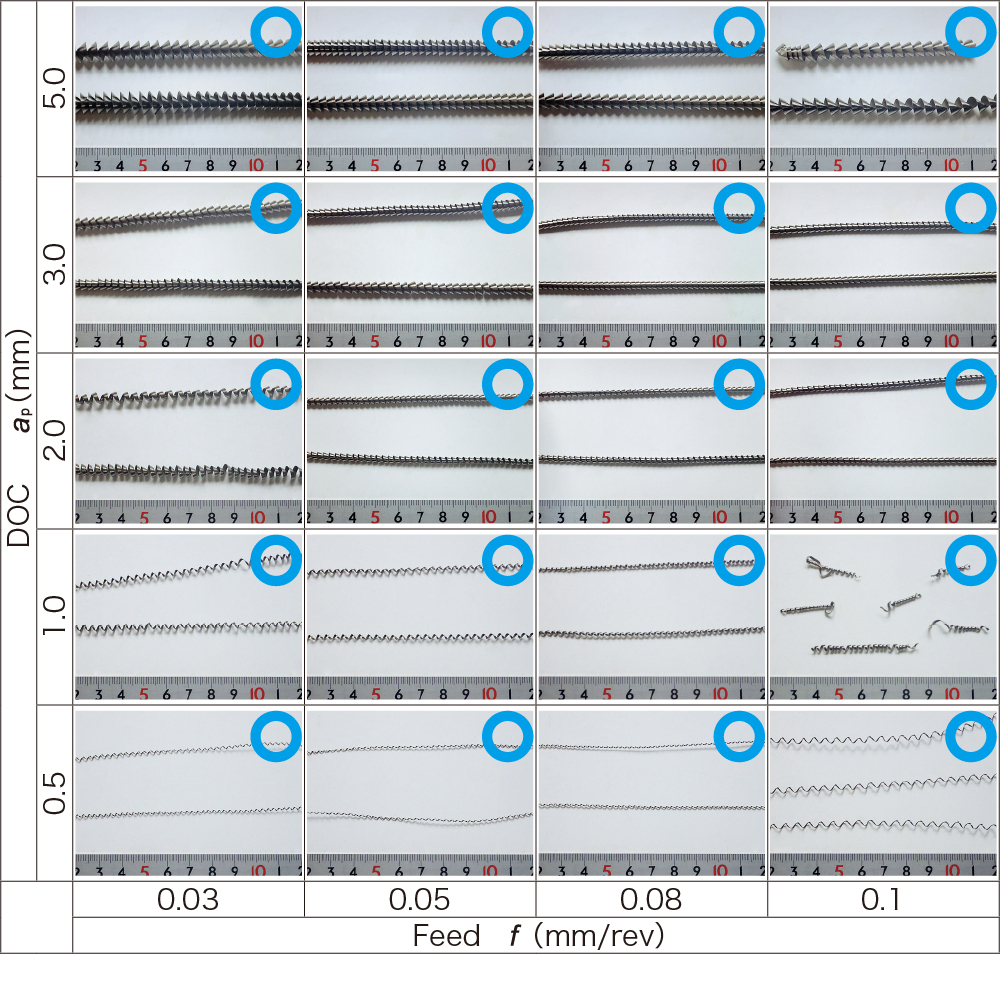

The current tool required 4 passes to remove the large amount of material.

TFX machined the same material removal in 1 pass.

The feed rate was reduced to improve chip control.

Cycle time was significantly shortened and tool life increased.

For more information about this product, visit our online e-catalog, or download the catalog/product report