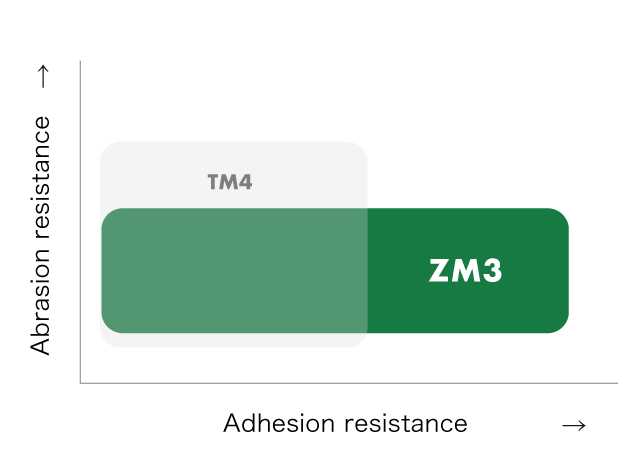

Versatile grade with excellent adhesion resistance | Carbide grade for Swiss CNC lathes

Wide range of work materials

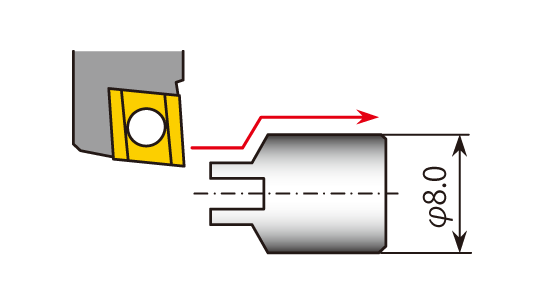

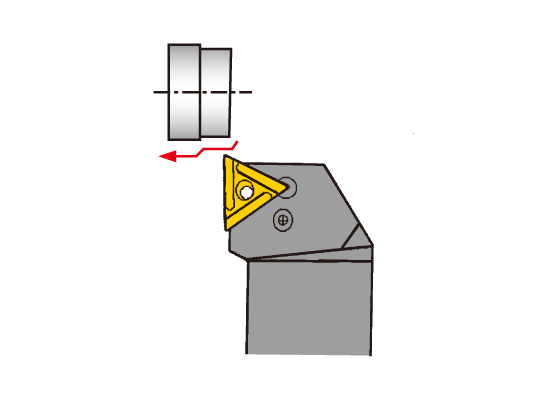

Front turning / Back turning / Grooving / Cut off / ID boring

| Electronic component | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| ZM3 |

1,300 pcs / corner

|

| Competitor’s PVD coated carbide |

1,000 pcs / corner

|

ZM3 was able to equal the surface finish while increasing tool life by 1.3 times that of the competition.

ZM3’s obtained a stable performance and long tool life due to the coatings adhesion resistance.

| Case | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| ZM3 |

6,000 pcs / corner and more

|

| Competitor’s PVD coated carbide | 150 pcs / corner |

ZM3 achieved 40 times the tool life compared to the competition with outstanding adhesion resistance and part dimensional consistency.

For more information about this product, visit our online e-catalog, or download the catalog/product report