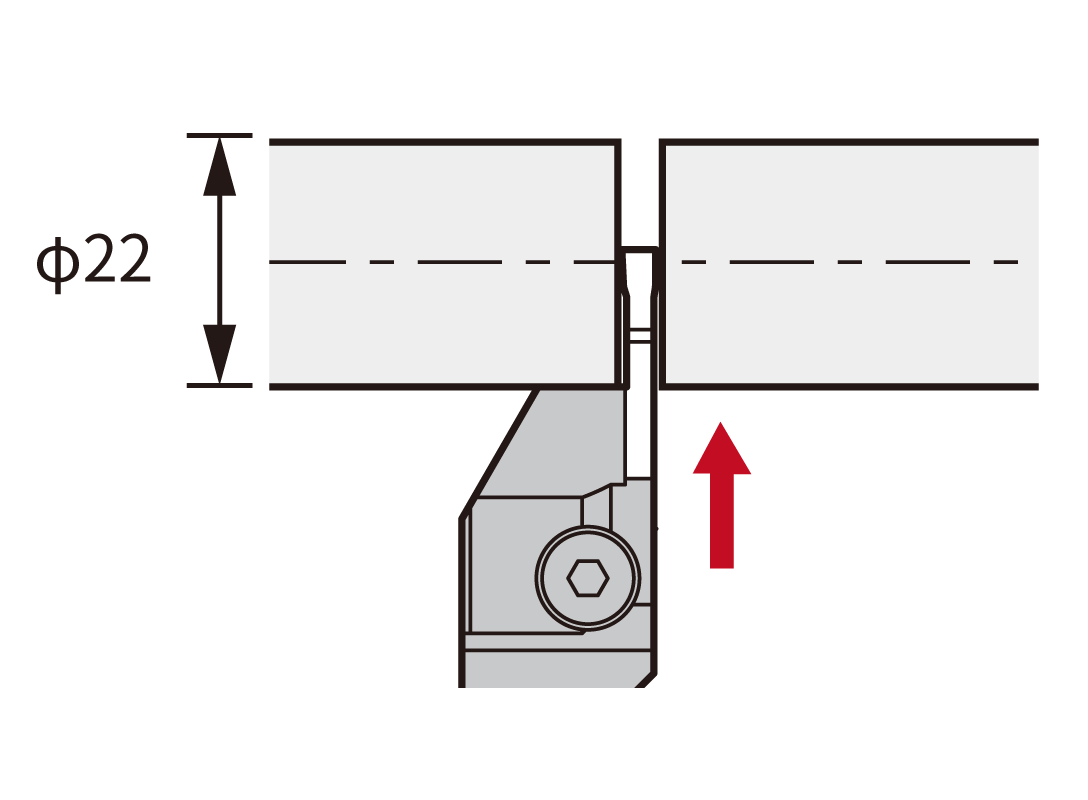

Cut-off operations for diameters up to 42mm 1.653” | Swiss CNC lathe / Conventional CNC lathe

Swiss CNC lathe / Conventional CNC lathe cut-off

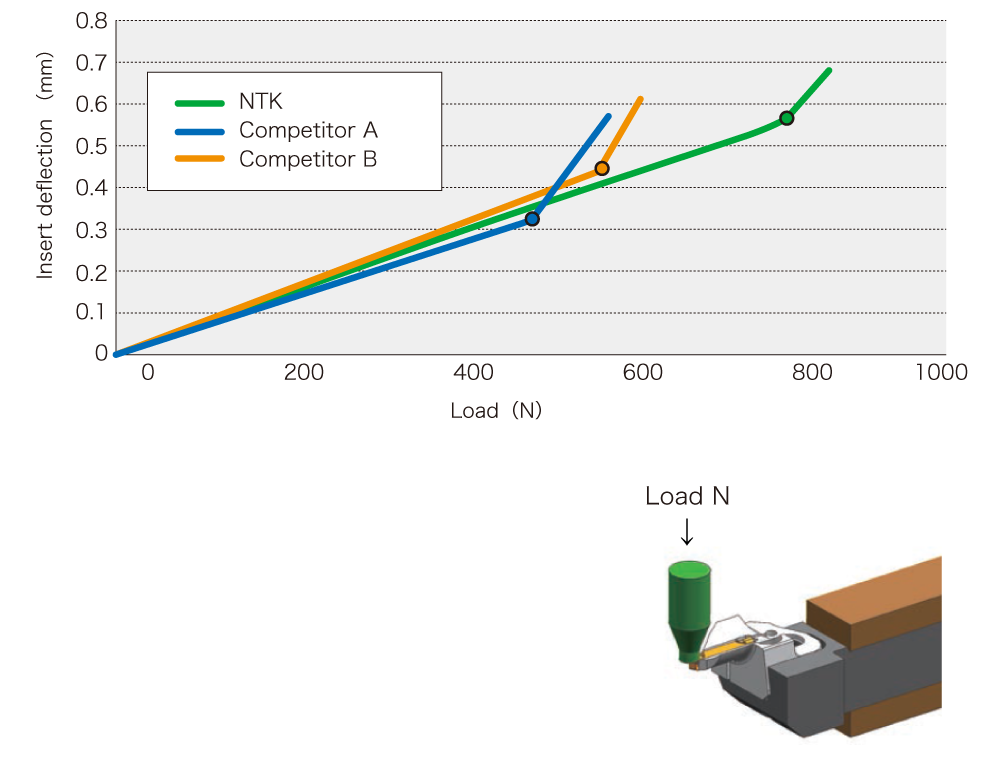

Rigidity developed to accommodate high load cut-off applications to ensure reliability and productivity.

* The highest clamping strength of any holder currently on the market (according to our research)

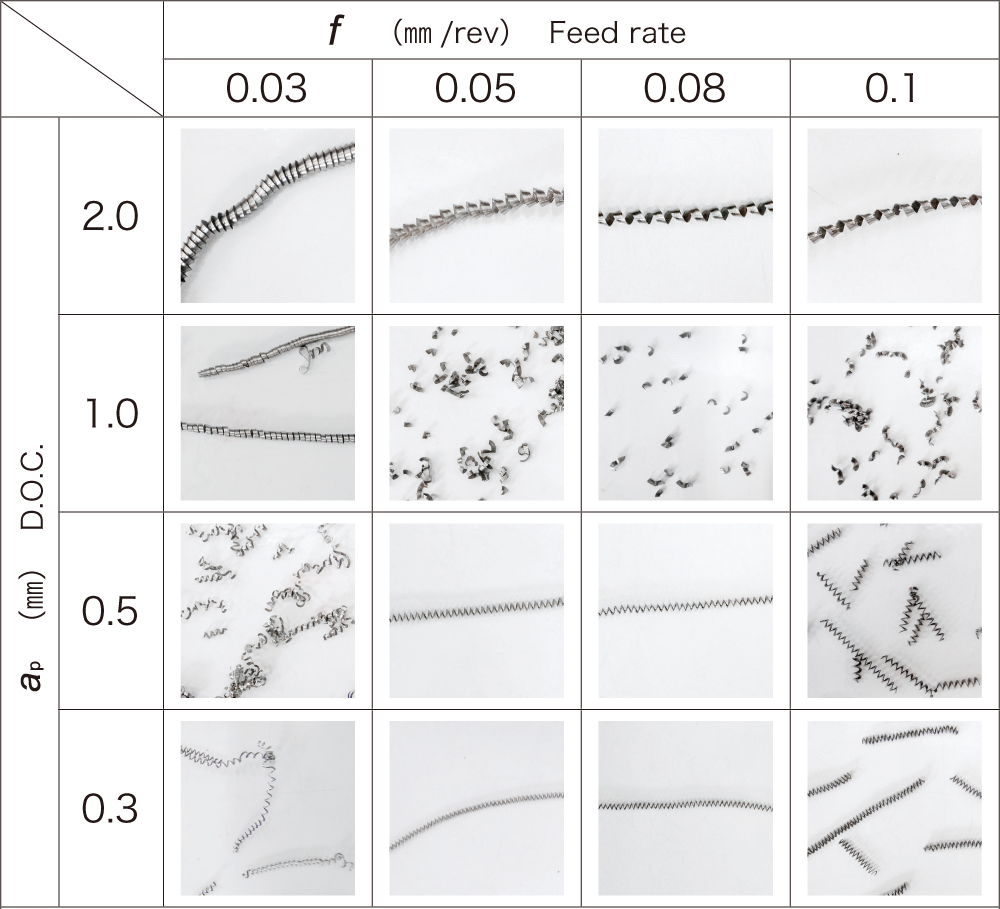

① Straight cutting edge improves toughness

② Folds chips from both edges for tight curls

③ High rake angle for increased sharpness

[ Cutting conditions ]

Material :

S45C ⌀42 vc = 100m/min

1045 ⌀1.653” 330 SFM

WET

[ Tools used ]

Insert : DM4 GWPFM300N02-GT Holder : CTWPR2020K-3D42

| Coated grade | Material | Operation type | Cut-off width (mm) Cut-off width (inch) | Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/rev) Feed (IPR) | Maximum cut-off diamter |

|---|---|---|---|---|---|---|

| DM4 | Difficult-to-cut material / titanium alloy / high temp alloys | Cut off | 3.0 .118 | 50 – 130 100 – 300 | 0.03 – 0.2 .0012 – .005 | ⌀42 ⌀1.653” |

| Coolant control parts | |

|---|---|

|

|

|

|

|

|

|

|

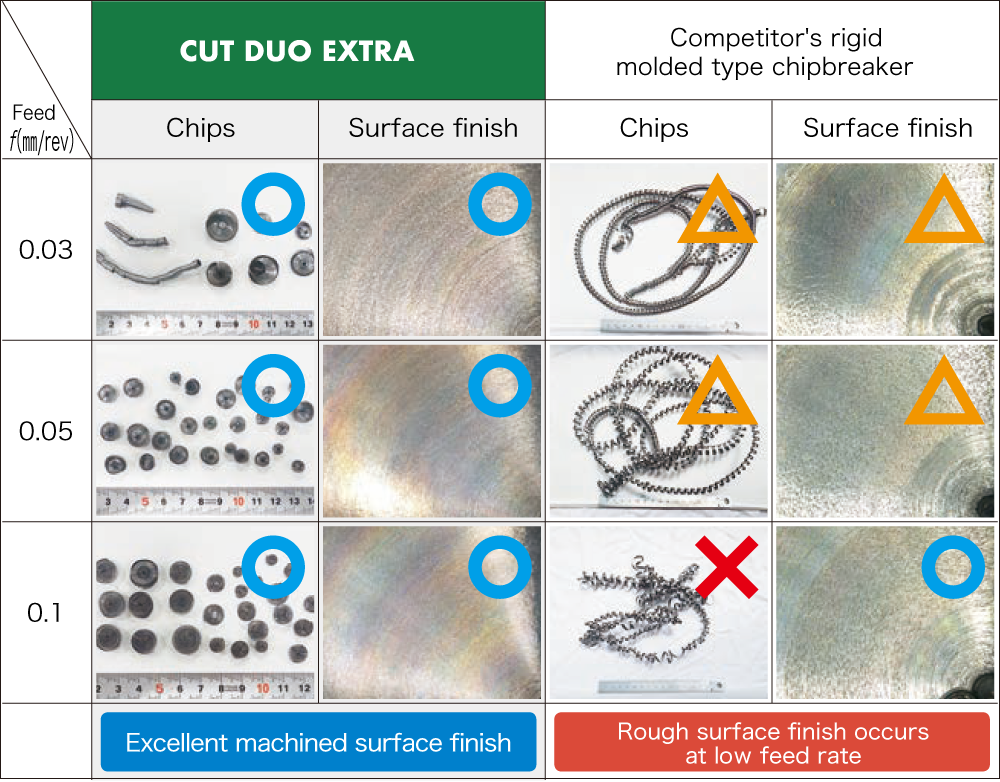

| CUT DUO EXTRA |

700 pcs / corner

|

| Competitor’s product |

350 pcs / corner

|

CUT DUO EXTRA with its 2 cutting edges significantly reduced cost compared to the competitor’s 1 cutting edge insert.

Cut Max achieved excellent chip control and 2 times the tool life.

For more information about this product, visit our online e-catalog, or download the catalog/product report