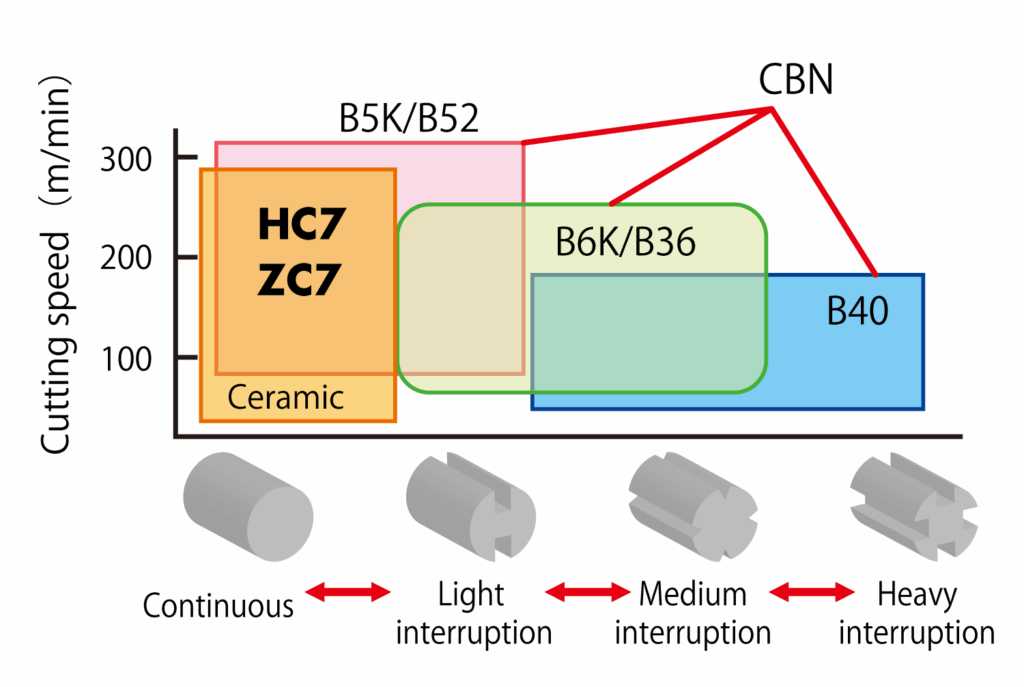

For continuous machining | Ceramic for machining materials 30 - 70 HRC

Hardened material

Continuous finish turning hardened materials 30-70HRC

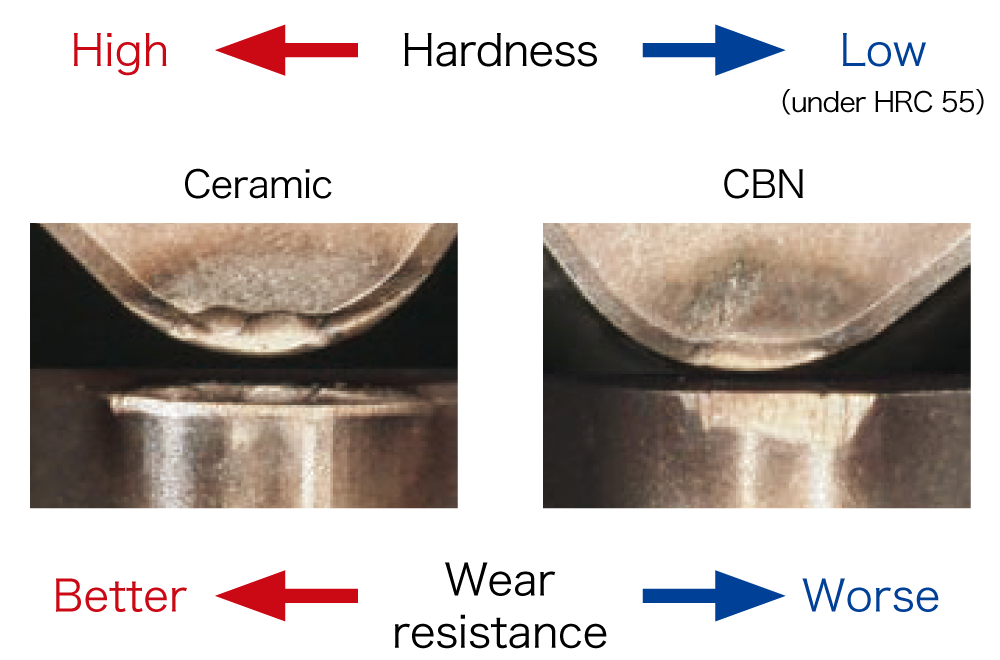

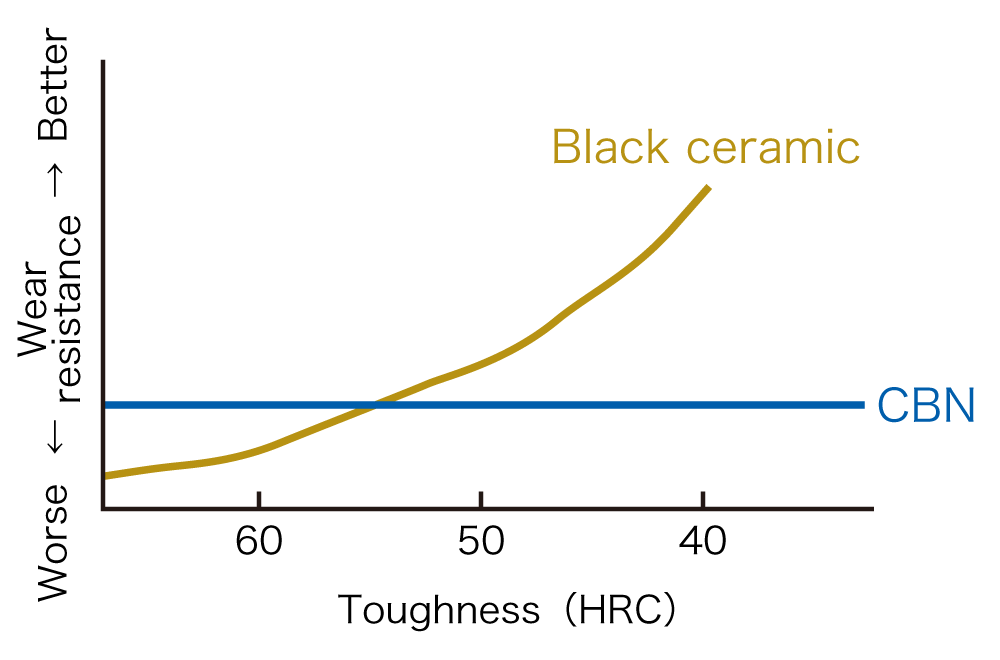

CBN’s low hardness reduces its wear resistance

Ceramic has superior wear resistance vs. CBN machining under HRC55

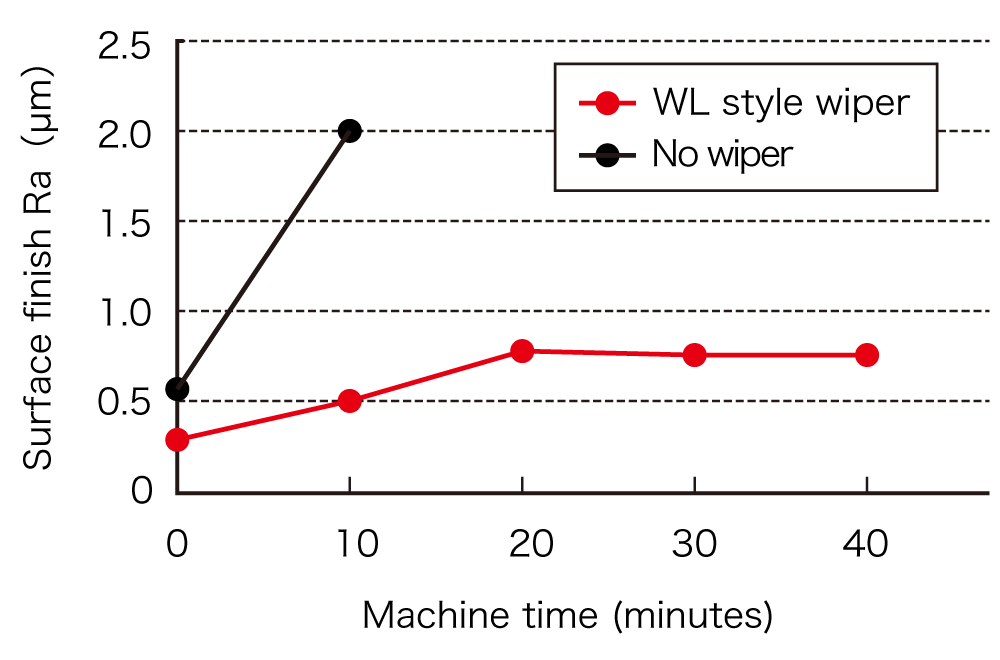

Effect of Wiper Flat on Cutting Edge

[ Cutting conditions ]

CNGA120412

Vc = 100m/min F = 0.1mm/rev ap = 0.5mm

330 SFM .004 IPR .020 DOC

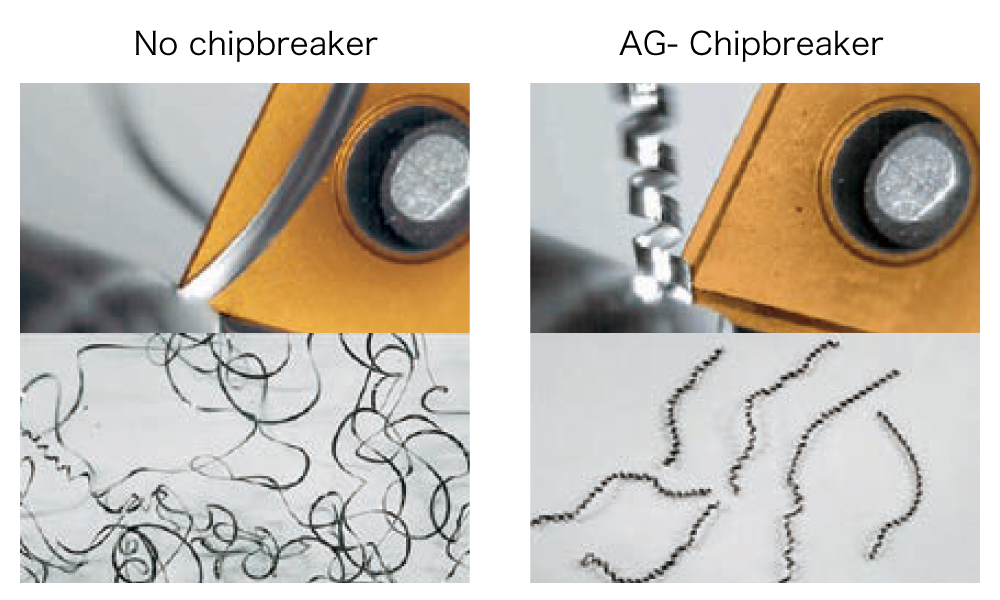

Using a ZC7 insert with AG-chipbreaker improves surface finish and reduces machine down-time due to chip tangling. This results in increased productivity.

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR) | DOC(mm) DOC(inch) | DRY | WET |

|---|---|---|---|---|---|---|---|---|

| ZC7 | Hardened material (HRC30-62) | Turning Continuous machining |

Finishing | 40 – 200 130 – 670 | 0.08 – 0.20 .003 – .008 | 0.12 – 0.8 .005 – .030 | – | ● |

| HC7 | Hardened material (HRC55-70) |

| Corner R | DOC (mm) DOC (inch) | Feed (mm /rev) Feed (IPR) |

|---|---|---|

| R0.4 R .016 | 0.15 0.007 | 0.05 ~ 0.08 .001 ~ .003 |

| R0.8 R .032 | 0.3 0.015 | 0.08 ~ 0.10 .003 ~ .004 |

| R1.2 R .047 | 0.4 0.02 | 0.10 ~ 0.13 .004 ~ .005 |

| R1.6 R .063 | 0.5 0.03 | 0.13 ~ 0.16 .005 ~ .006 |

| Round insert | 2.0 0.08 | 0.16 ~ 0.25 .006 ~ .010 |

For more information about this product, visit our online e-catalog, or download the catalog/product report

Other recommend products