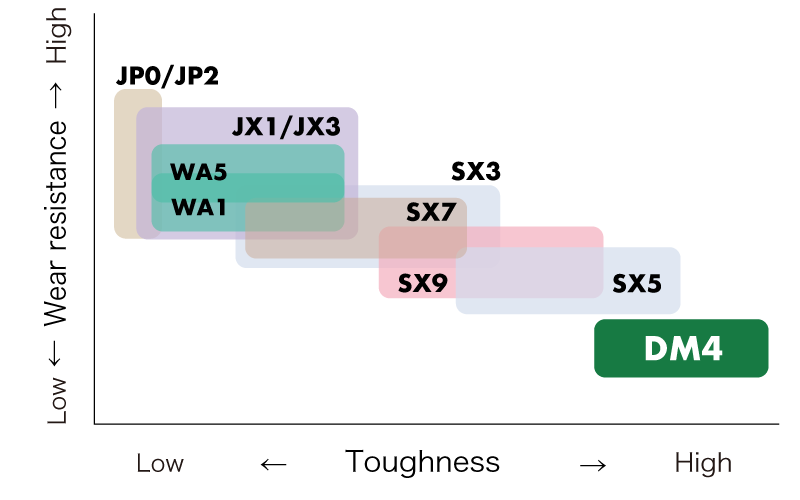

Difficult-to-cut materials | PVD coated carbide

Difficult to cut materials: heat resistant alloys and titanium alloys

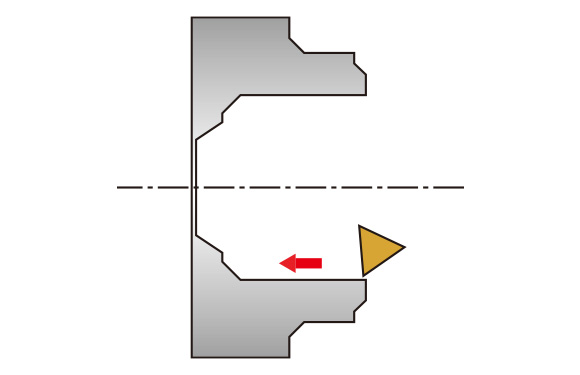

Finish Turning / Grooving

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR) | DOC(mm) DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|

| DM4 | Difficult to cut materials (heat resistant alloys) | Turning | Finishing | 20 – 50 65 – 164 | 0.03 – 0.15 .001 – .006 | 0.1 – 1.0 .004 – .040 | WET |

| Grooving | 0.05 – 0.20 .002 – .008 | – |

| Case (finishing) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| DM4 |

110 pcs / corner

|

| Competitor’s PVD coated carbide |

90 pcs / corner

|

For more information about this product, visit our online e-catalog, or download the catalog/product report