Roughing to semi-finishing of heat resistant alloys | BIDEMICS

Finishing Heat resistant alloys

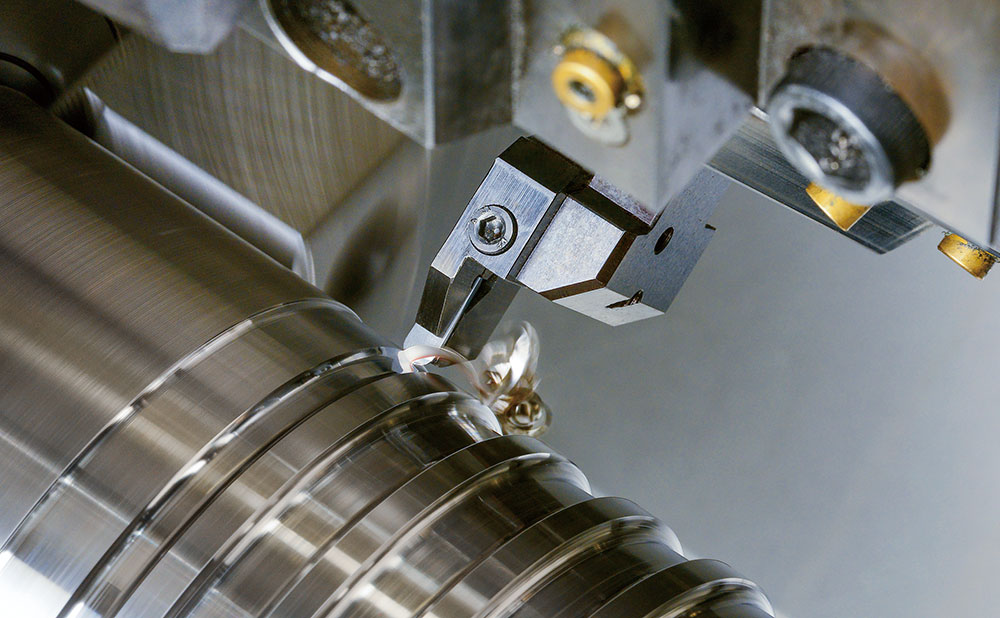

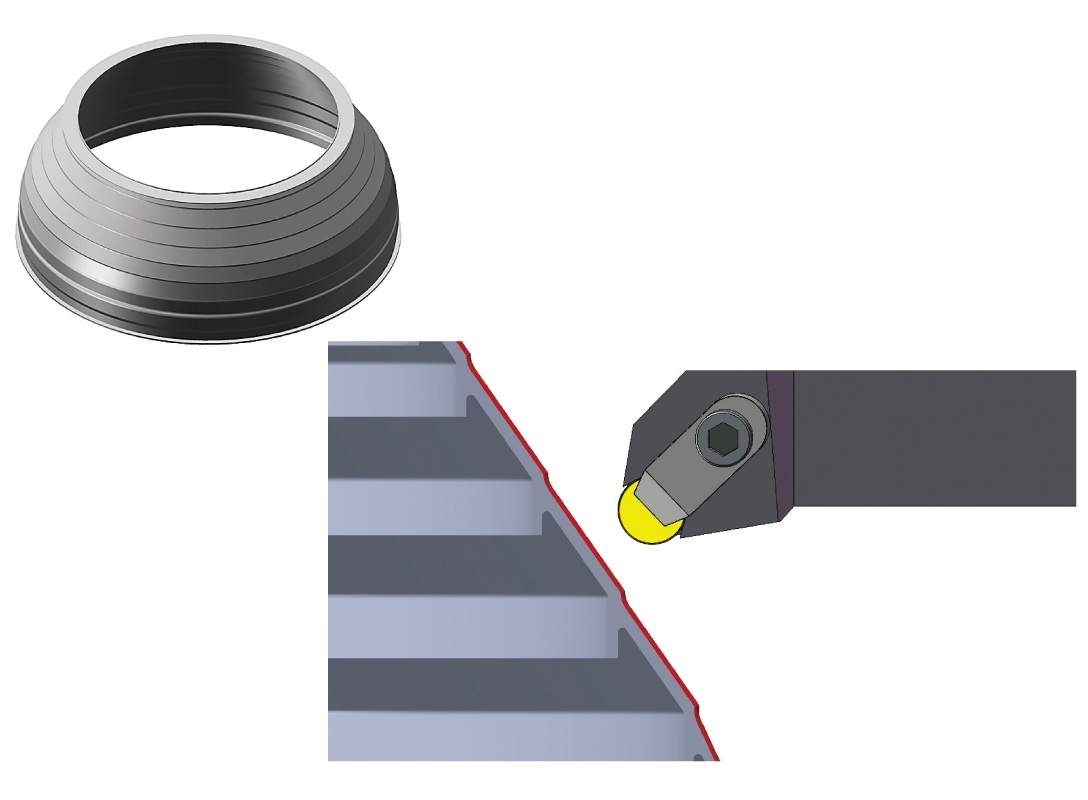

Turning / Grooving / Profiling / Roughing to Semi-finishing

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR) | DOC(mm) DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|

| JX1/JX3 | Heat resistant alloys | Turning | Roughing (no scale) | 180 – 480 600 – 1600 | 0.12 – 0.27 005 – .011 | 1.0 – 2.5 .040 – .080 | WET |

| Profiling / Semi-finishing | 0.10 – 0.25 .004 -.010 | 1.0 – 2.0 .020 – .080 | |||||

| Grooving | 0.05 – 0.10 .002 – .004 | – |

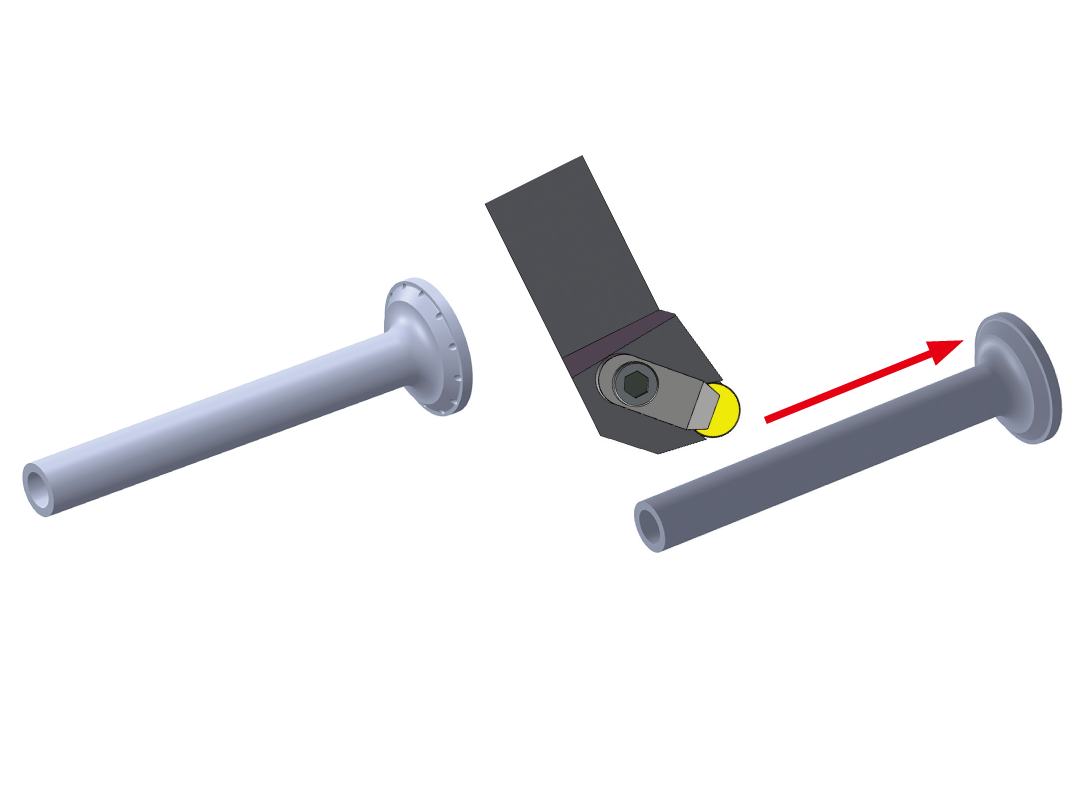

| Turbine shaft (Inconel – no scale) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| JX1 |

10min

|

| Competitor’s whisker ceramic |

3min

|

Long tool life

JX1 combines strength and excellent thermal conductivity for improved performance compared to whisker ceramics.

BIDEMICS outperformed with dramatically better tool life when run at same parameters as the whisker ceramic insert.

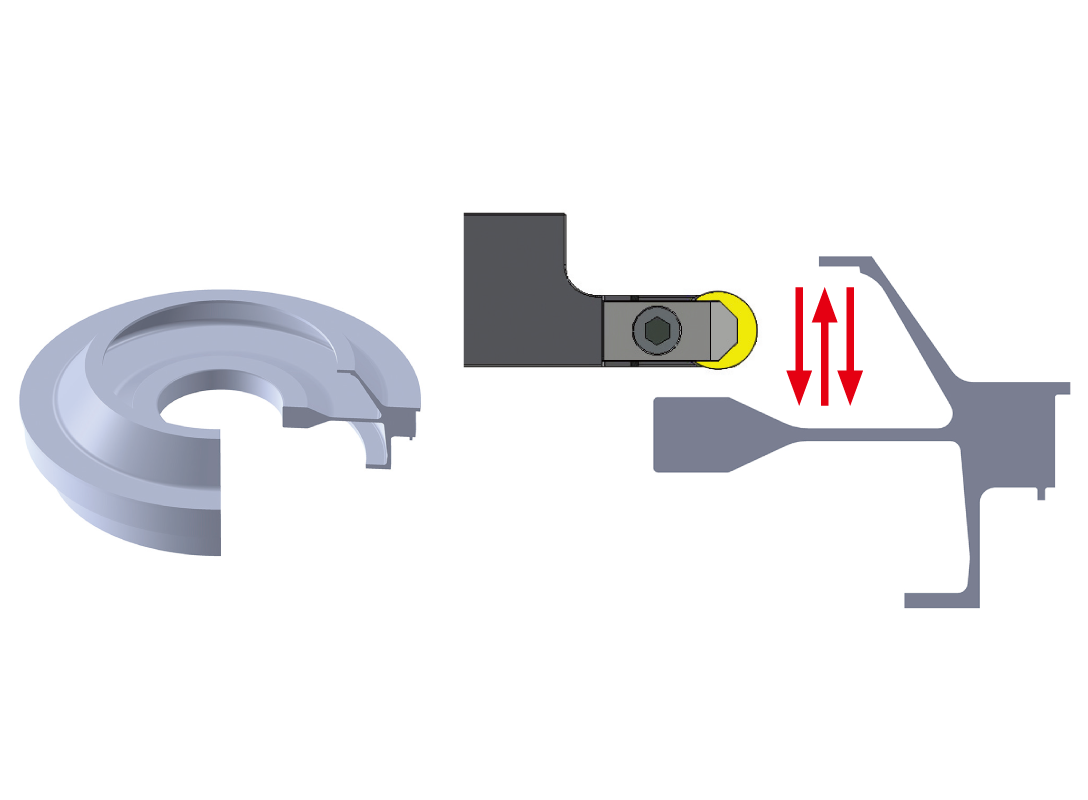

| Turbine disc (Inconel – roughing) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| JX1 |

120 cc/min

|

| Competitor’s whisker ceramic |

60 cc/min

|

Faster speeds

BIDEMICS has excellent material characteristics to allow for high-speed machining.

JX1 machined at double the cutting speeds to improve productivity and eliminated the need for capital investments to improve production.

| Turbine case (Inco 718 Plus – semi-finishing) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| JX1 |

3 pass

|

| Competitor’s coated whisker |

1 pass

|

Machines a wide range of heat resistant alloys

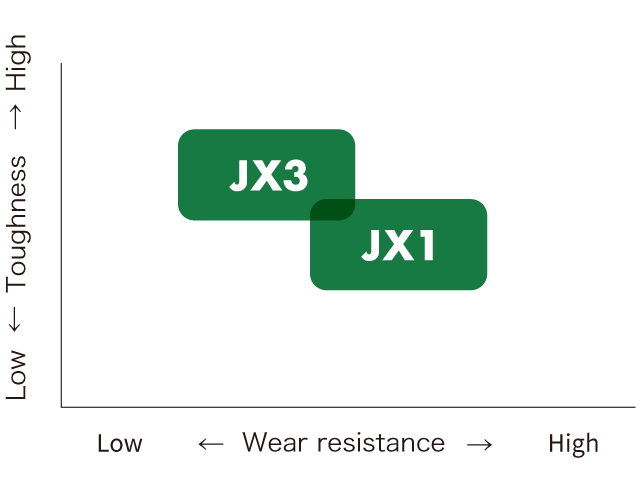

Unique material characteristics of JX1/JX3 allow them to machine difficult to cut materials such as high nickel / high cobalt / powdered metals / heat resistant alloys which have recently become more common in the market.

Continuous chips are typical when machining heat resistant alloys but at higher cutting speeds the chips break easily.

For more information about this product, visit our online e-catalog, or download the catalog/product report