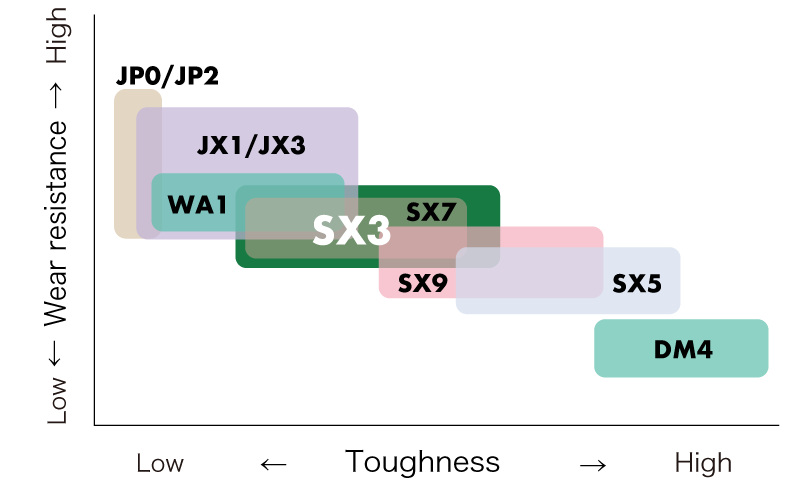

Roughing & semi-finishing heat resistant alloys | Sialon ceramic

Finishing Heat resistant alloys

Turning / Profiling / Milling: Roughing with scale to semi-finishing

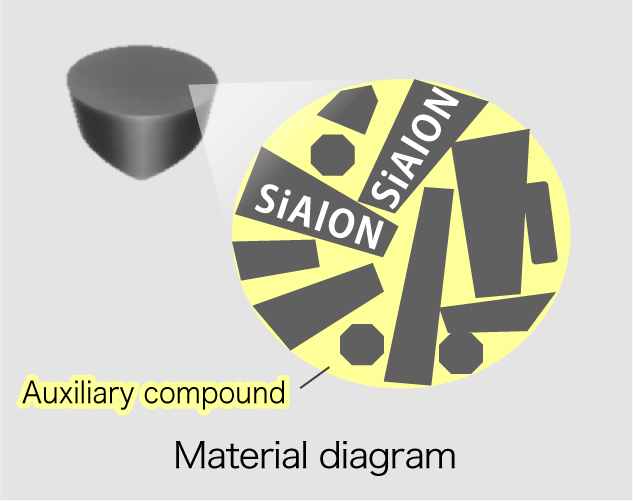

Silicon nitride (Si3N4) is combined with Aluminum (Al) and oxygen (O) to make SiAlON.

Sialon has needle-shaped particles similar to that of Silicon nitride.

The arrangement of these particles makes the material withstand the impact force during cutting.

The addition of the alumina improves its heat resistance characteristics.

The property advantages makes it perfect for machining heat resistant alloys.

| ISO | Work material | Coolant | Grade | vc (m/min) (SFM) | ap (mm) (inch) | f (mm/rev) (IPR) |

|---|---|---|---|---|---|---|

| Heat-Resistant Super Alloy Scale Turning |

WET | SX3 | 180 – 270 600 – 900 | 1.0 – 5.0 .040 – .200 | 0.1 – 0.22 .004 – .010 | |

| Heat-Resistant Super Alloy Rough Turning (Without Scale) |

WET | 180 – 270 600 – 900 | 1.0 – 2.5 .040 – .100 | 0.15 – 0.3 .006 – .012 | ||

| Heat-Resistant Super Alloy Mid-Finish Turning |

WET | 180 – 270 600 – 900 | 1.0 – 2.0 .040 – .080 | 0.12 – 0.25 .004 – .010 | ||

| Heat-Resistant Super Alloy Grooving |

WET | 180 – 270 600 – 900 | – | 0.07 – 0.15 .003 – .006 | ||

| Heat-Resistant Super Alloy Rough Milling |

DRY | 600 – 1200 2000 – 4000 | 1.0 – 2.5 .040 – .100 | 0.07 – 0.12 .003 – .004 |

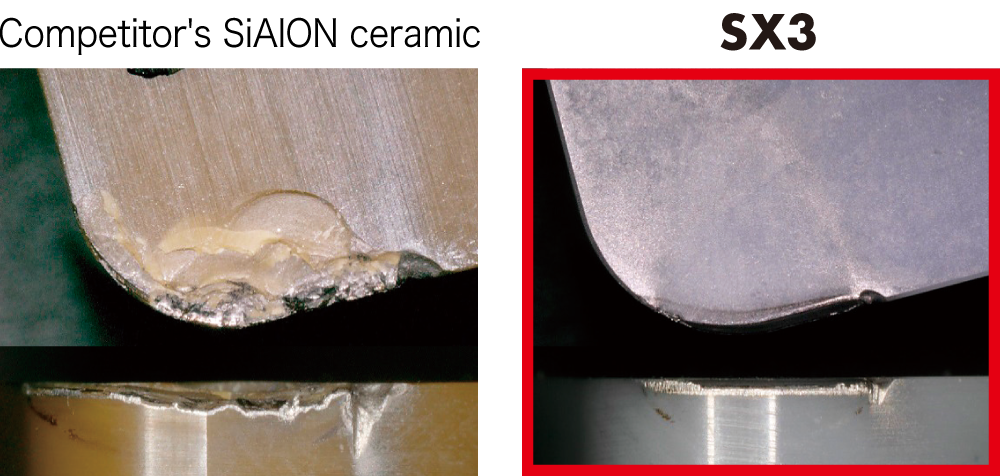

| Rene130 Roughing with scale | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| SX3 |

10.0min

|

SX3 insert machined through the scale and inspection yielded no defects on insert edge.

Competitor’s Sialon insert evaluation yielded visible breakdown of cutting edge after same machining operation.

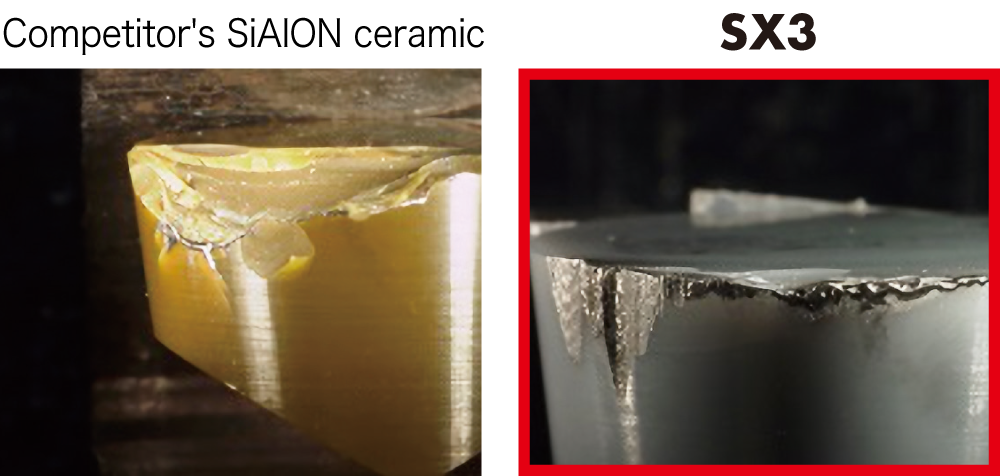

| Semi-finishing Rene 130 | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| SX3 |

10.0min

|

SX3 and SX9 both maintained good edge conditions after cuts while the competitor’s Sialon insert exhibited signs of significant wear.

For more information about this product, visit our online e-catalog, or download the catalog/product report