Tools for mill roll turning | Ceramic and CBN inserts

Ceramic insert advantage

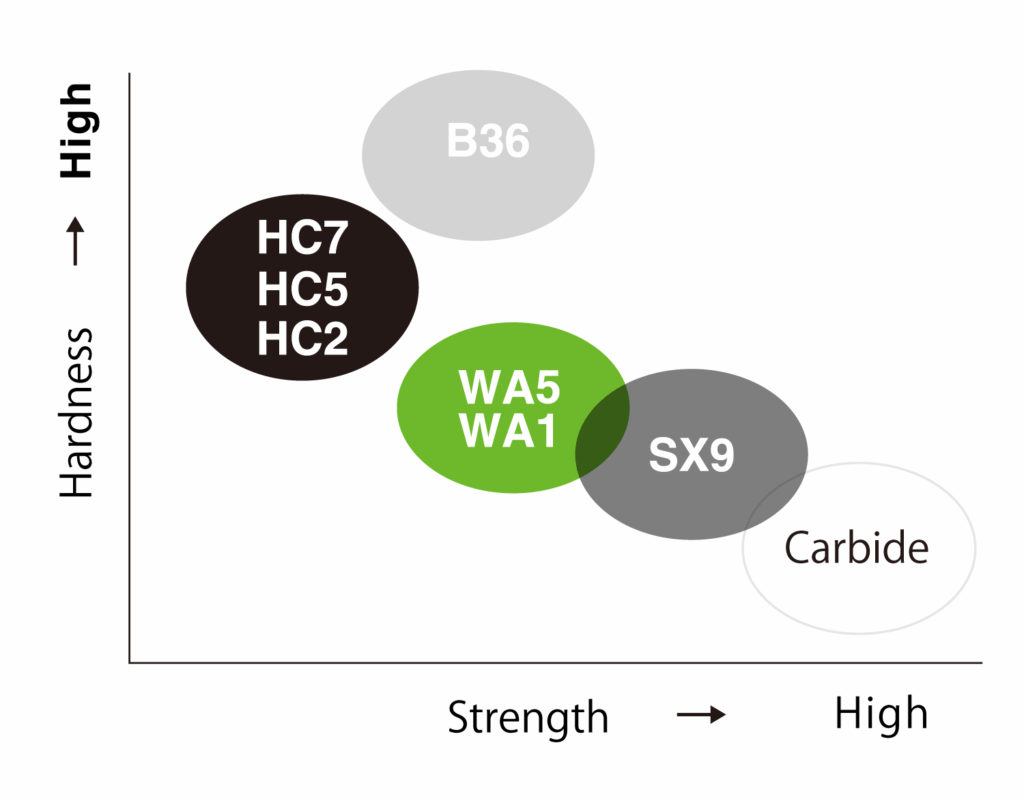

CBN grades:

Turning mill roll materials

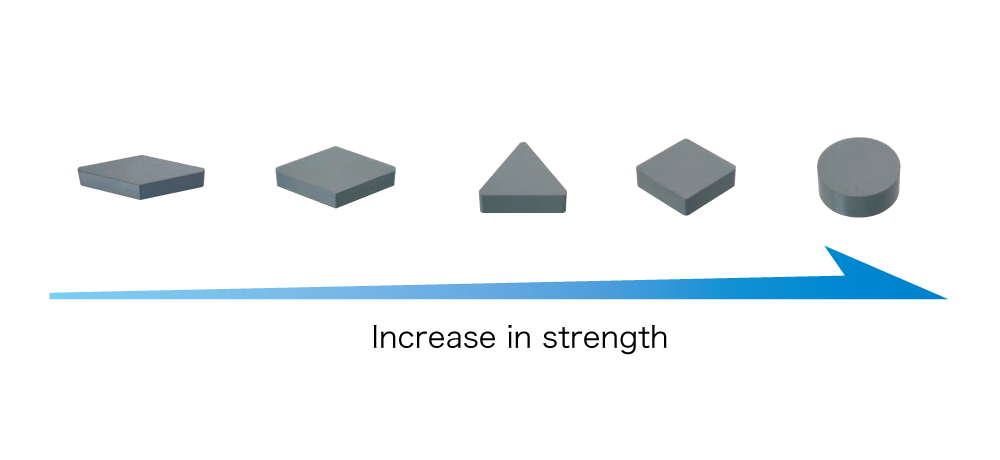

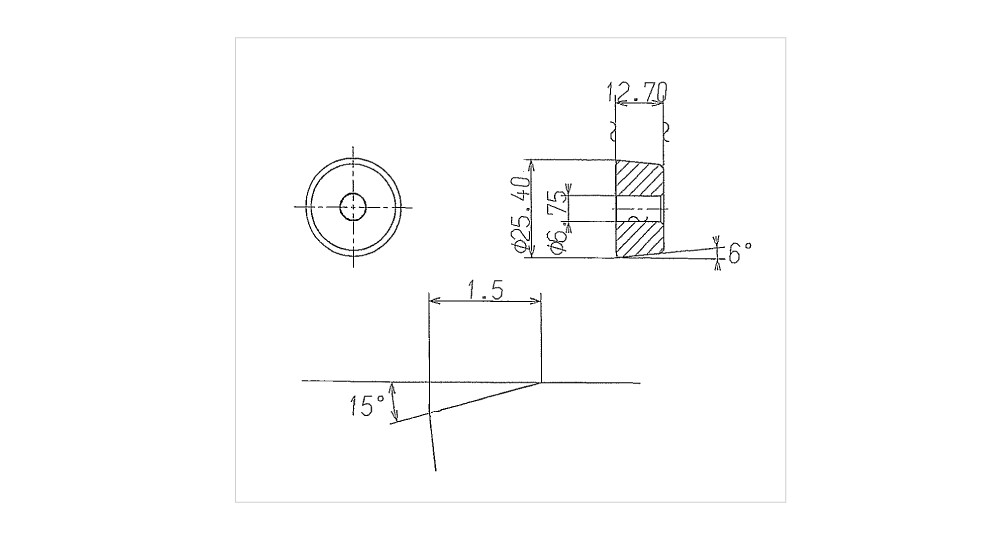

① shape characteristic

Edge strength increases as the insert geometry angle increases.

Note that as the insert strength increases so do cutting forces.

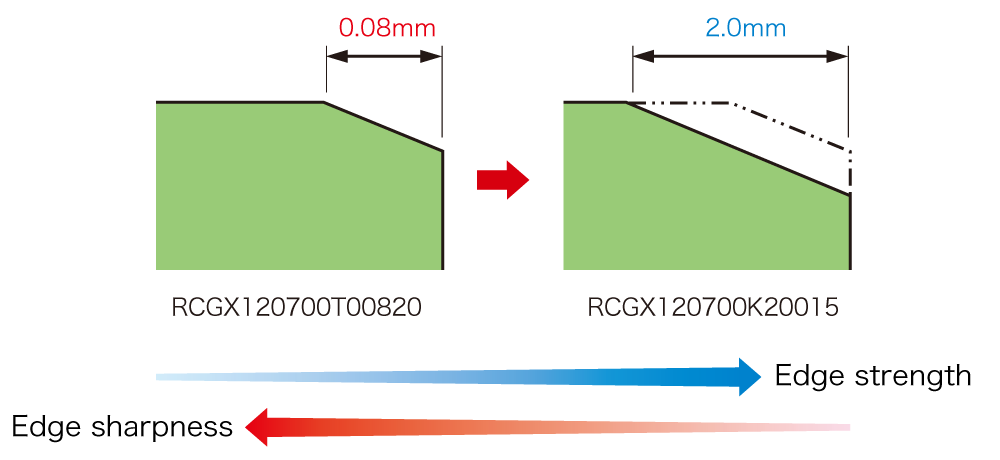

② edge preparations

Insert damage can be reduced by increasing the edge preparation.

Insert machining stability will be improved during roughing.

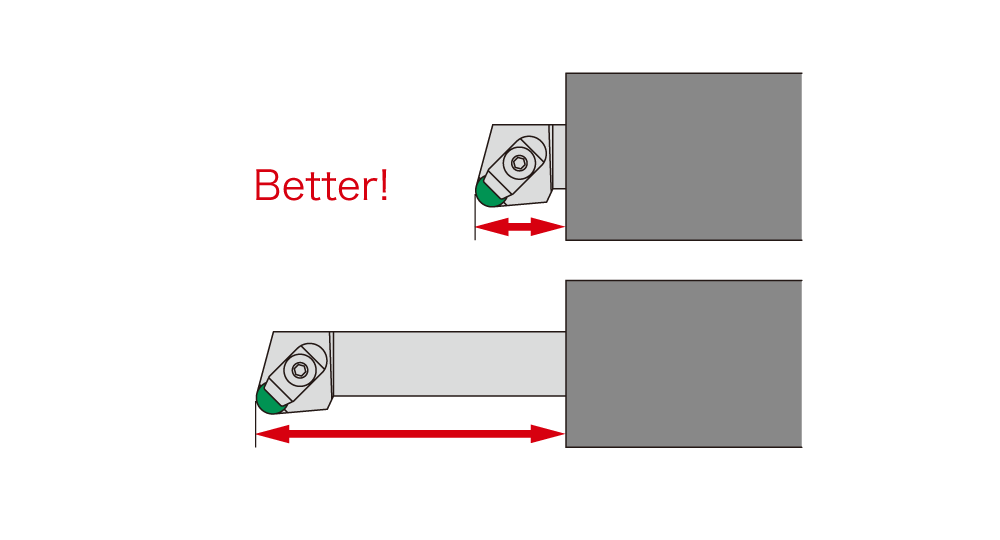

③ Minimize overhang

By minimizing the toolholder overhang the setup is more rigid and eliminates chatter. (a main cause of insert chipping)

NTK provides specialized tools with industry specific insert geometries and coordinated holders.

| Roll material | Application | Grade | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR) | DOC(mm) DOC(inch) | DRY | WET |

|---|---|---|---|---|---|---|---|

| High speed steel (HHS) roll | Rough to semi-finishing | Whisker ceramic WA1/WA5 | ~ 40 ~ 130 | 0.3 – 0.5 .012 – .020 | * 5-15% of insert diameter (approximate) | ● | – |

| Finishing | CBN B22/B36 | ||||||

| Hardened steel roll | Semi-finish to finishing | Alumina ceramic HC2/HC7 | 80 – 200 260 – 660 | 0.5 – 0.8 .020 – .030 | ● | – | |

| Finishing | CBN B22/B36 | ||||||

| Cast iron roll Chilled iron roll |

Semi-finish to finishing | Alumina ceramic HC2/HC7 | 40 – 80 130 – 260 | 0.3 – 0.5 .012 – .020 | ● | – | |

| Finishing | CBN B22/B36 | ||||||

| Cast iron roll Ductile cast iron rolls CPM rolls (ex. Powdered metal) Carbide rolls |

Rough to semi-finishing | Silicon nitride ceramic SX9 | 40 – 120 130 – 400 | 0.5 – 0.8 .020 – .030 | ● | – | |

| Finishing | CBN B22/B36 | ||||||

| Carbide rolls | Rough to semi-finishing | Whisker ceramic WA1/WA5 | ~ 40 ~ 130 | 0.3 – 0.5 .012 – .020 | ● | – | |

| Finishing | CBN B22/B36 |

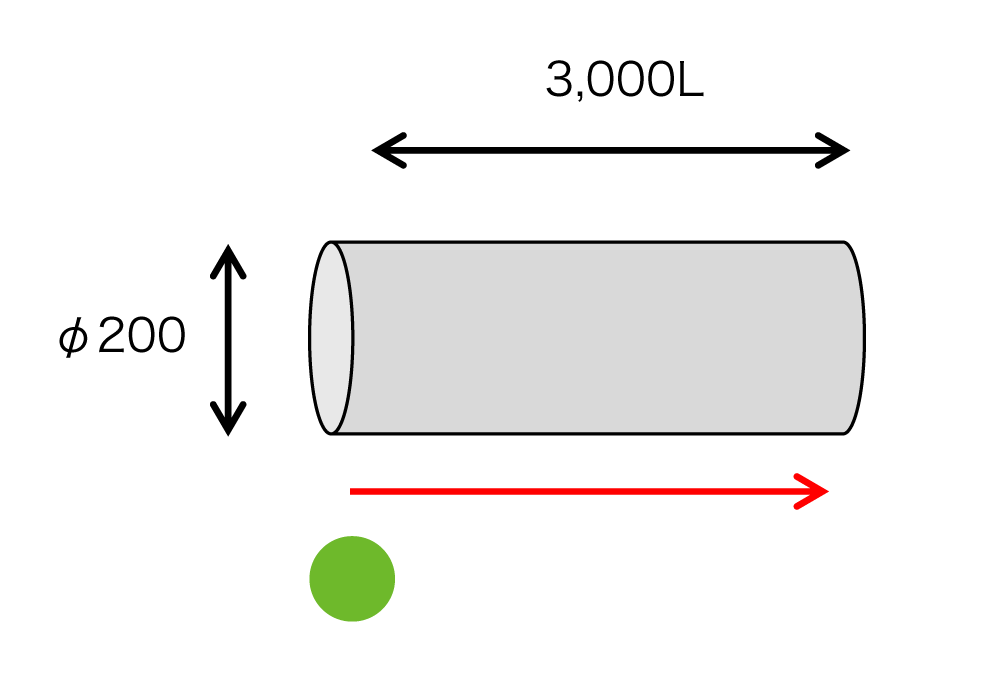

| Forming roll | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| HC7 |

2 pcs/ corner

|

| Competitor’s black ceramic |

1 pcs/ corner

|

HC7 performed with 2 times longer tool life compared to competitor’s black ceramic.

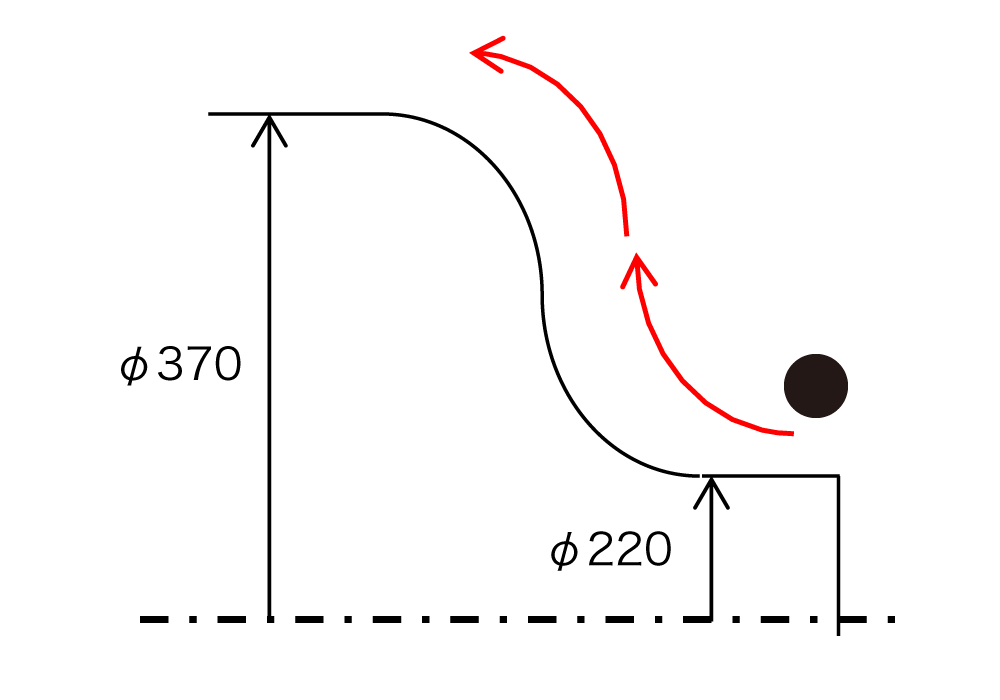

| Bending roll | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| WA1 |

2 pcs(6,000L)/ corner

|

| Competitor’s black ceramic |

1 pcs(3,000L)/ corner

|

WA1 achieved twice the tool life compared to competitor’s black ceramic.

Customer: “I had always used the same black ceramic product, but now I see the performance difference between products.”

For more information about this product, visit our online e-catalog, or download the catalog/product report