Milling tools for finishing aluminum alloys PCD inserts

Features

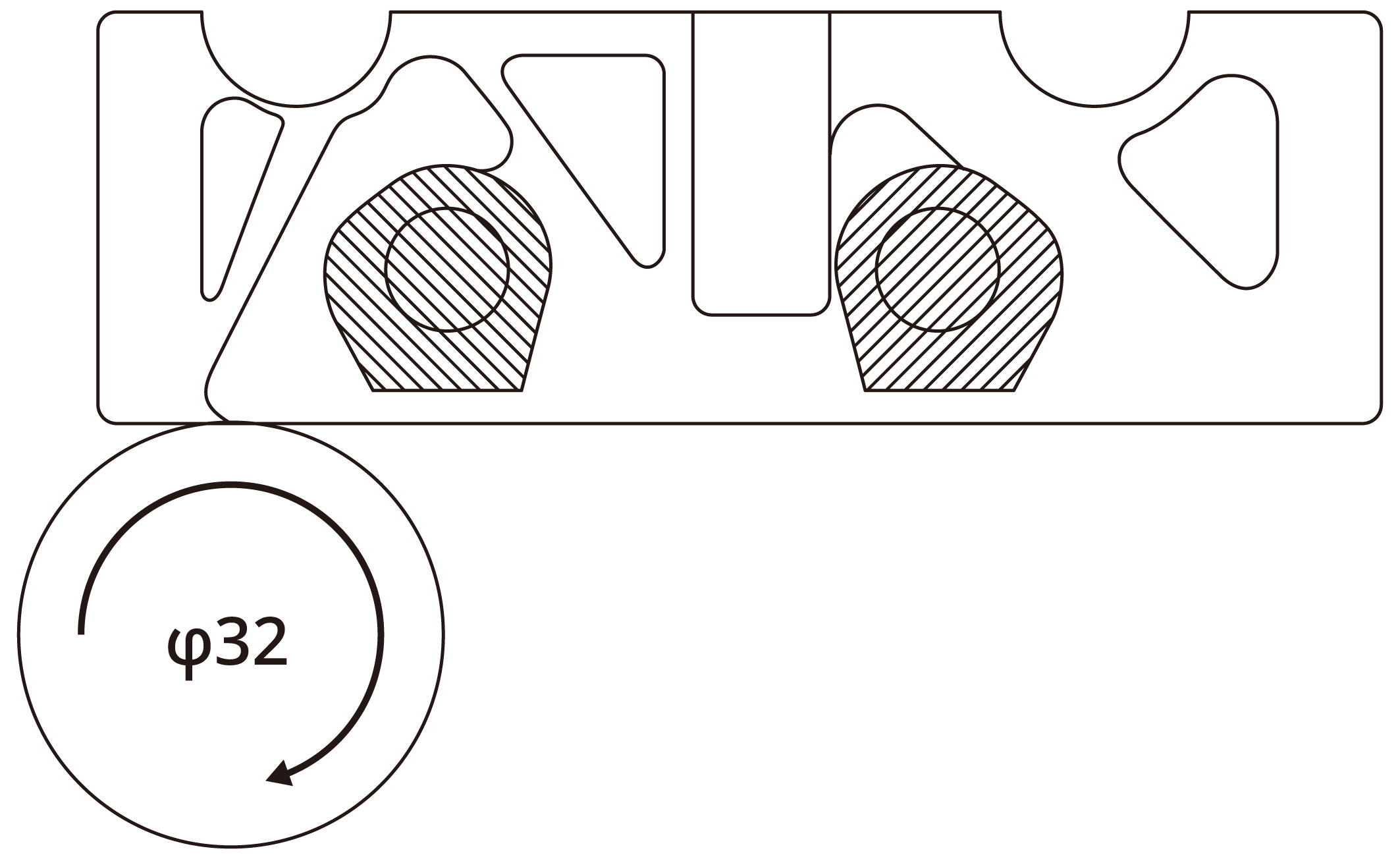

| Cutting of rocker shaft holder | |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PD1 |

15,000 pcs / corner (Ongoing) |

| Competitor’s PCD |

8000 pcs / corner |

This cutter reduced the total cycle time by 3 minutes.

| Cutting of under holder | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

|

||

| PD1 |

24,000 pcs / corner (Ongoing)

|

|

| Competitor’s PCD ⌀ 50 2” ×4 |

10000 pcs / corner

|

|

| Competitor’s PCD ⌀ 32 1.25” ×3 |

2500 pcs / corner

|

|

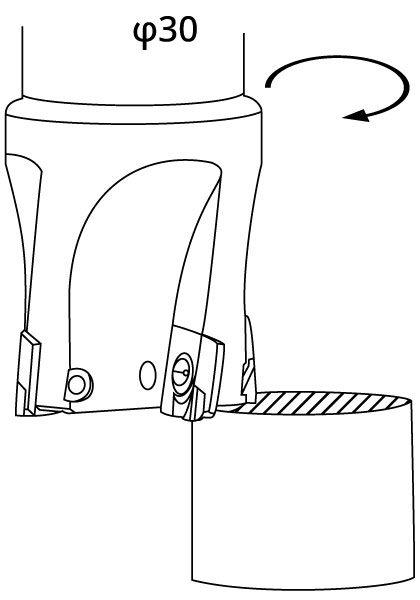

No chipping of the carbide inserts occurred.

Due to good performance, the current ⌀

32

1.25”

and ⌀

50

2”

have been unified to ⌀

30

1.2”

.

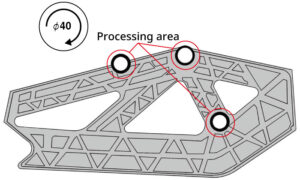

| Cutting of rail frame (for two-wheel) | |

|---|---|

|  |

| |

| |

| |

| |

| |

| |

| |

| |

| PD1 | 30,000 pcs / corner |

| Competitor’s PCD | 10~20 pcs / corner |

This cutter has resulted in a significant increase in lifespan and efficiency.

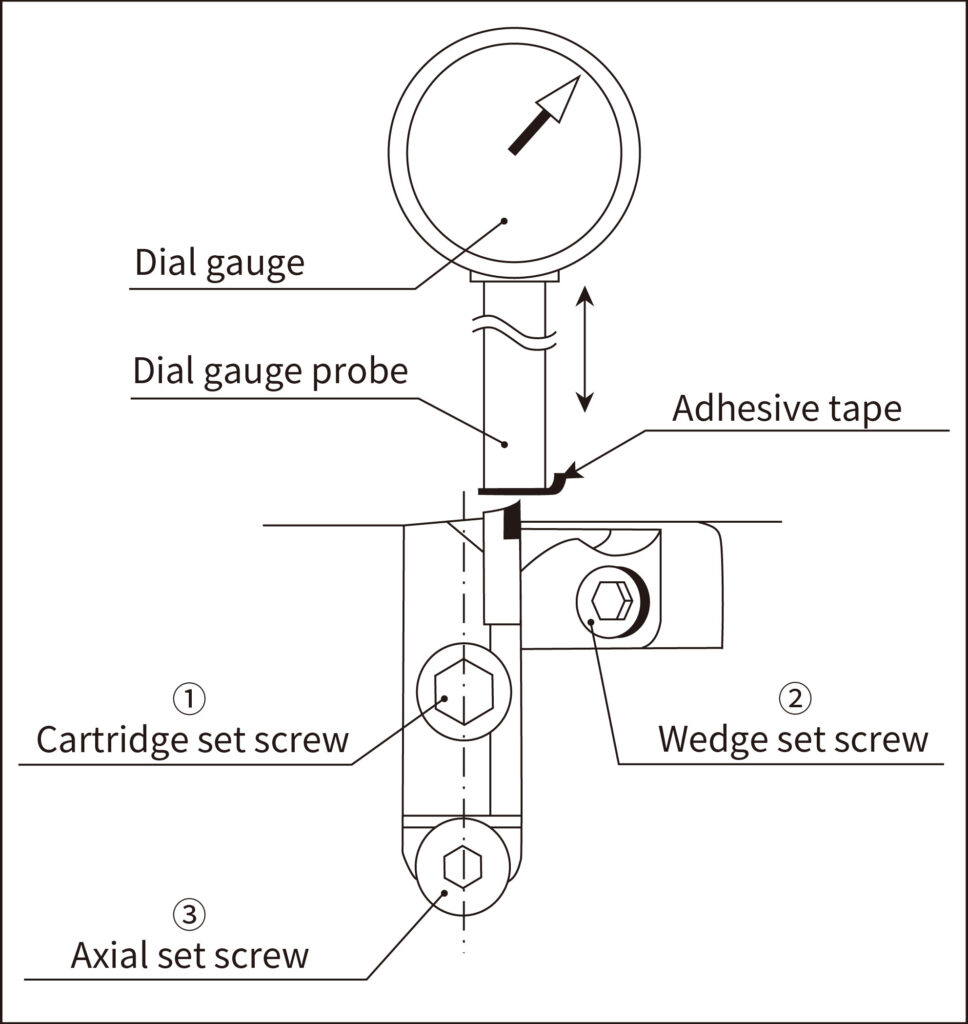

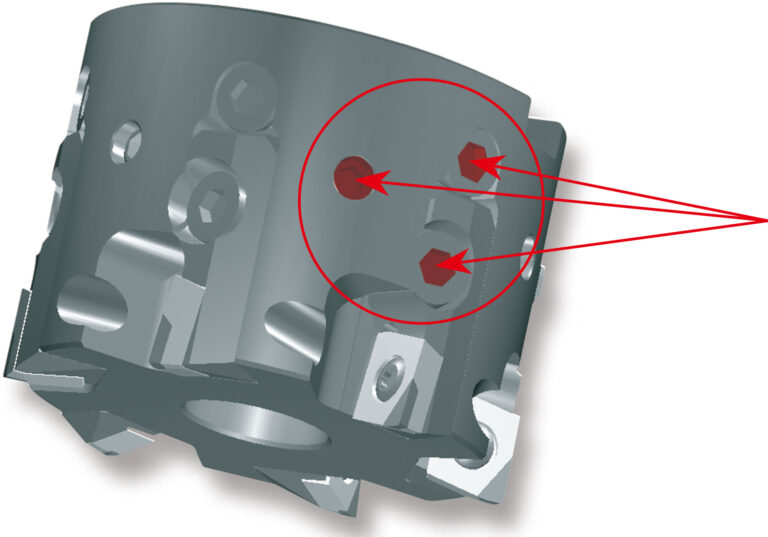

■Be sure to clean all the insert pockets before carrying out the following steps:

■Supplemental explanation

No need for pre-setting

No need for cutting edge adjustments!

(The only requirement is clamping and unclamping of the inserts with the clamping bolt)

【Note】

The holes for the axial set screws and balance adjusting screws are filled with a special material, thus, no screwdrivers and hex-wrenches can be inserted in them.

※The color of the special material is different from the color of the actual product body.

For more information about this product, visit our online e-catalog, or download the catalog/product report