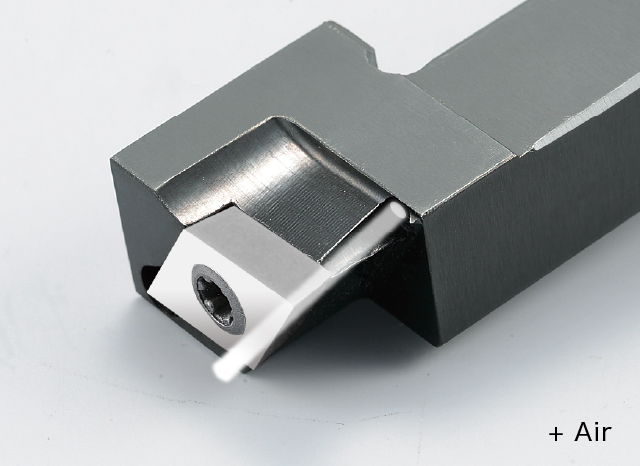

For turning small parts | Y-axis holder + KM1 Insert

Automatic lathe (Gang type) machining plastic materials (PEEK/PTFE, etc.)

Front turning (ISO) / Back turning / Grooving / Cut-off / Threading / Boring

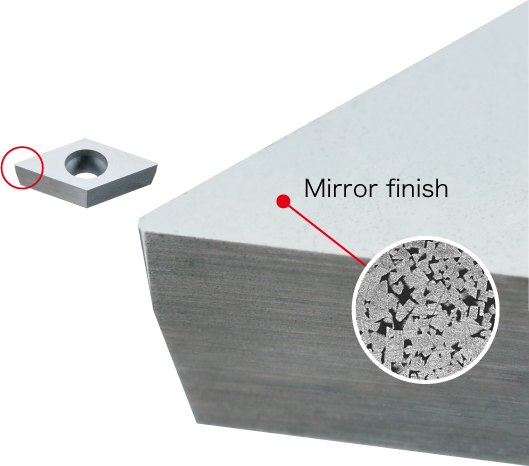

Excellent surface finish using an insert featuring an up-sharp edge and polished mirror-finish for welding resistance.

| Grade | Material | Operation | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/rev) Feed (IPR) | DOC (mm) DOC (inch) | DRY | AIR |

|---|---|---|---|---|---|---|---|---|

| KM1 | Plastic (PEEK,PTFE,etc.) | Turning | Roughing – Finishing | 50 – 150 164 – 490 | 0.05 – 0.10 .002 -.004 | 0.5 – 3.0 .020 – .118 | ● | ● |

| Medical implant | |

|---|---|

|

PEEK |

|

100 328 |

|

0.06 .0023 |

|

2.50 .010 |

|

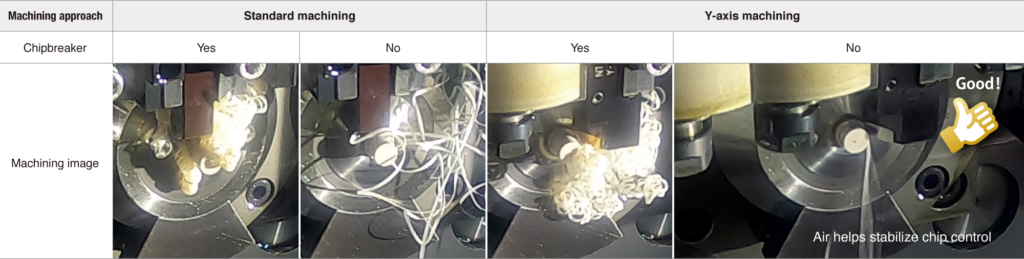

NTK:AIR Competitor:DRY |

| KM1 VCGT11T302H No chipbreaker |

80 pcs / corner

|

| Carbide VCGT11T302 Molded chipbreaker |

40 pcs / corner

|

| Automotive component | |

|---|---|

|

PEEK (with glass fiber) |

|

NTK:120

NTK:394

Competitor:40 Competitor:131 |

|

NTK:0.08

NTK:.003

Competitor:0.05 Competitor:.002 |

|

0.25 .010 |

|

NTK:AIR Competitor:DRY |

| KM1 DCGT11T302H No chipbreaker |

3 pcs / corner

|

| PVD Carbide VNMG160408 Molded chipbreaker |

1 pcs / corner

|

For more information about this product, visit our online e-catalog, or download the catalog/product report