seriesCoolant through toolholders | Swiss CNC Lathes

seriesCoolant through toolholders | Swiss CNC Lathes

Extensive selection of styles and sizes

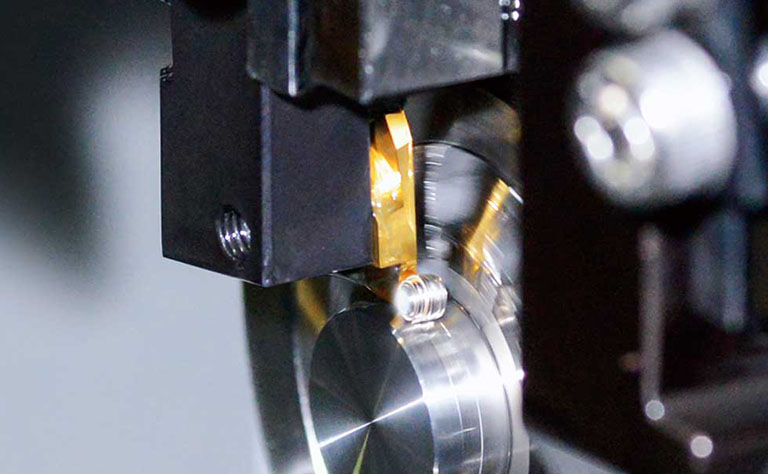

Holder system to solve chip concerns

Directs coolant to evacuate chips, reduce cycle time, and cools cutting edge to increase tool life.

Product video

Features

- Coolant is directed to control chip removal

- Improves stability of machining environment

- Supplies coolant directly to cutting edge to control heat and slow down edge wear

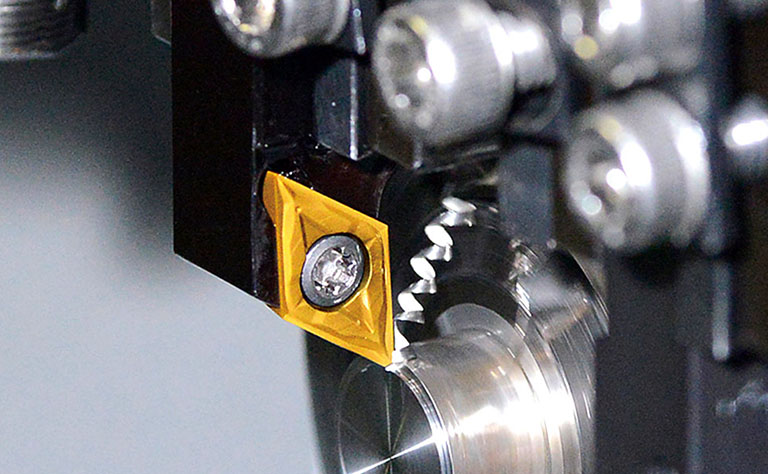

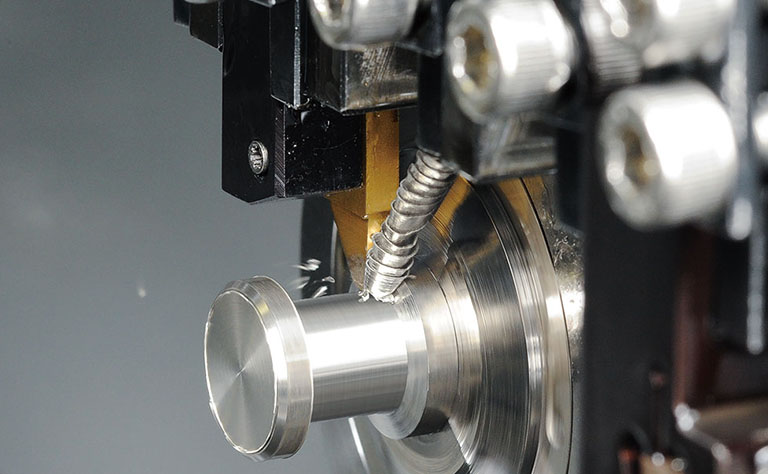

Tooling application

Front turning / Back turning / Grooving / Threading / Cut off / ID boring

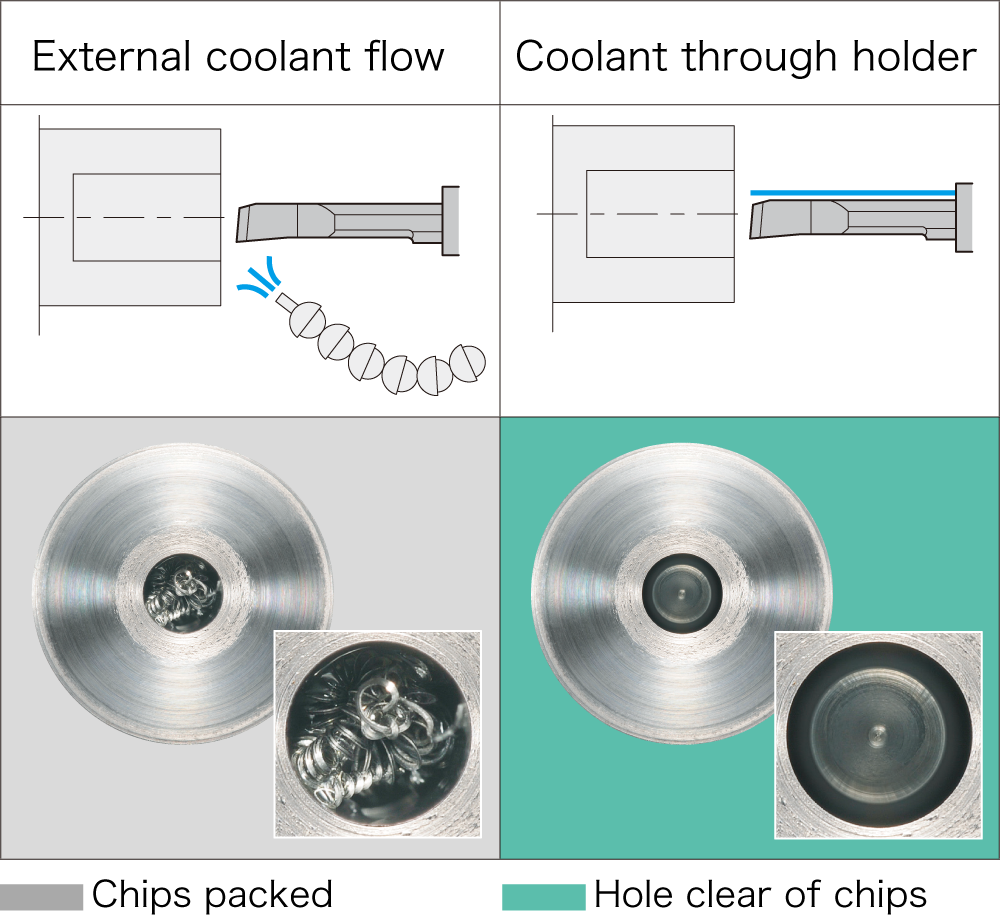

ID boring operation - coolant flow comparison

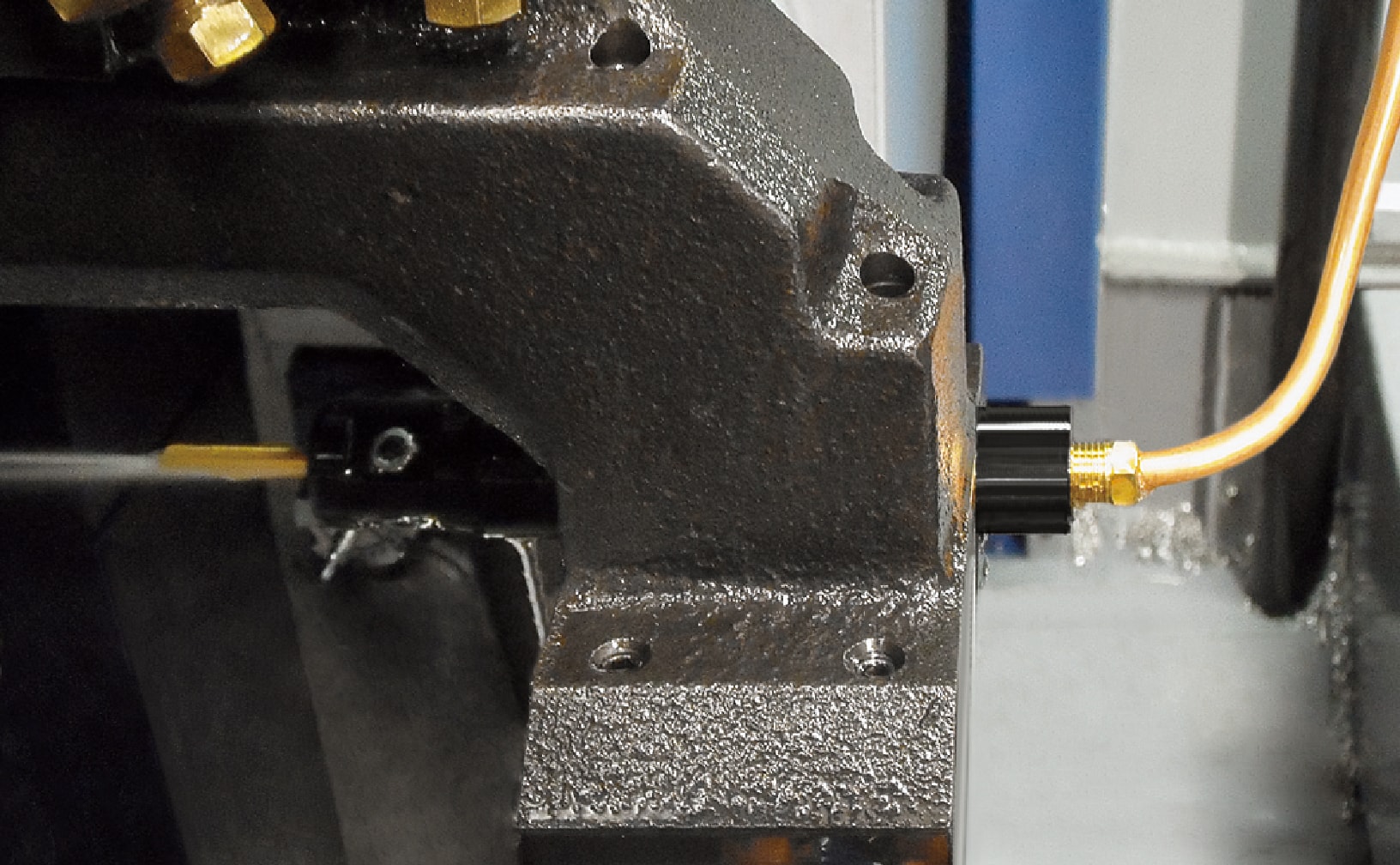

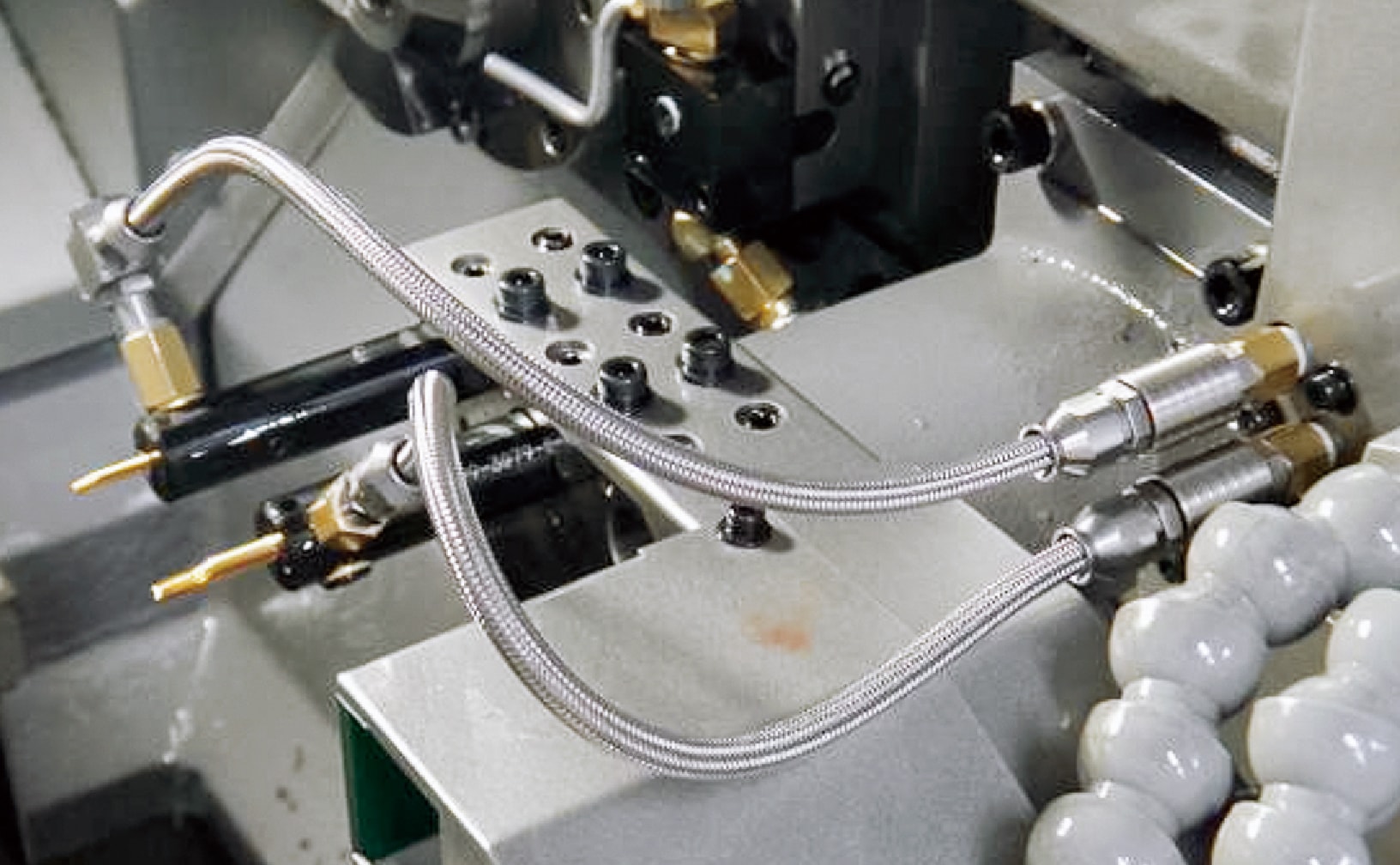

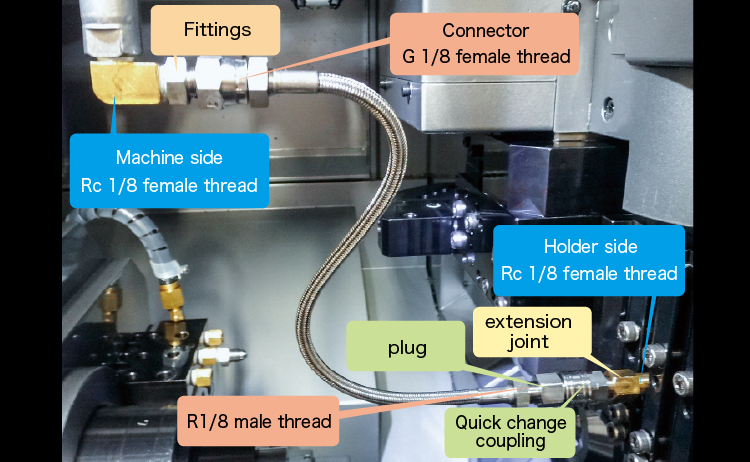

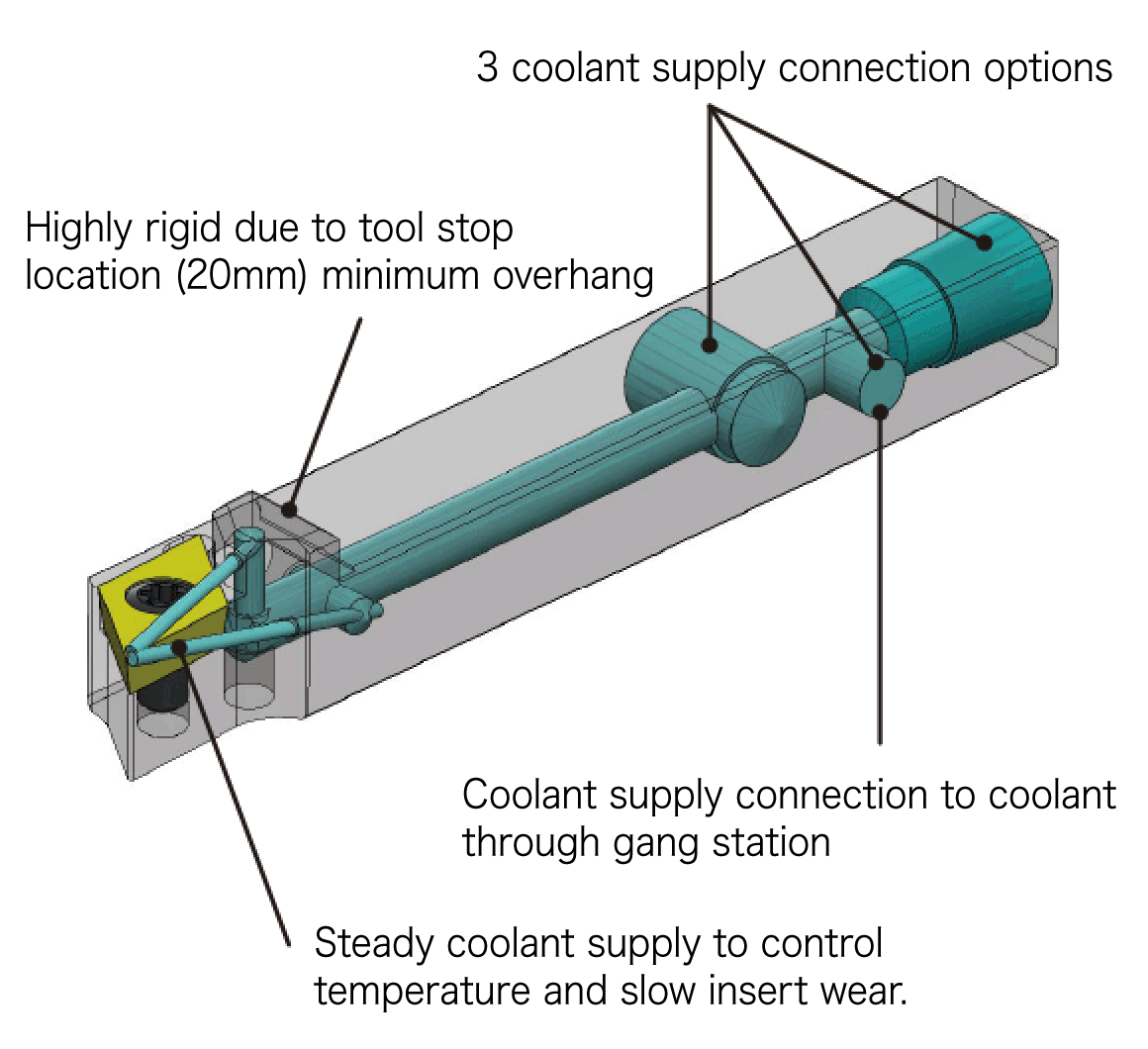

Compatible with various coolant hose connections

Holder side connection option

Holder rear connection option

ID boring holder side connection

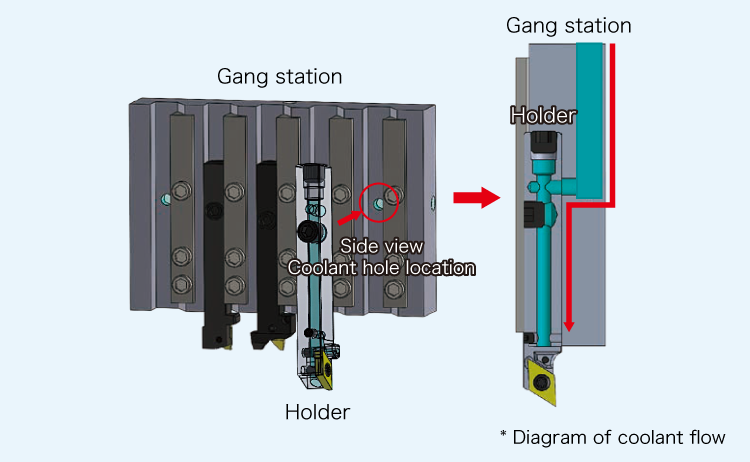

Hose mounting example (vertical gang style)

New hose free coolant system

Coolant supplied directly from the gang station to holder

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

YL chipbreakerFor front turning operations | Swiss CNC Lathes

First recommendation for front turning

-

TBP/TBPA-BM chipbreakerBack turning | Swiss CNC Lathes

Unique chipbreaker provides excellent chip evacuation

-

GX chipbreakerFor grooving | Swiss CNC Lathes

Solves the issue of chips wrapping around workpiece or remaining in the groove

-

CTP/CTPA-CX chipbreakerFor cut-off operations with max. diameter up to 16mm| Swiss CNC lathes

Tightly curls chips to prevent tangling

Useful information

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining

The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining

Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining "Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab

"Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab