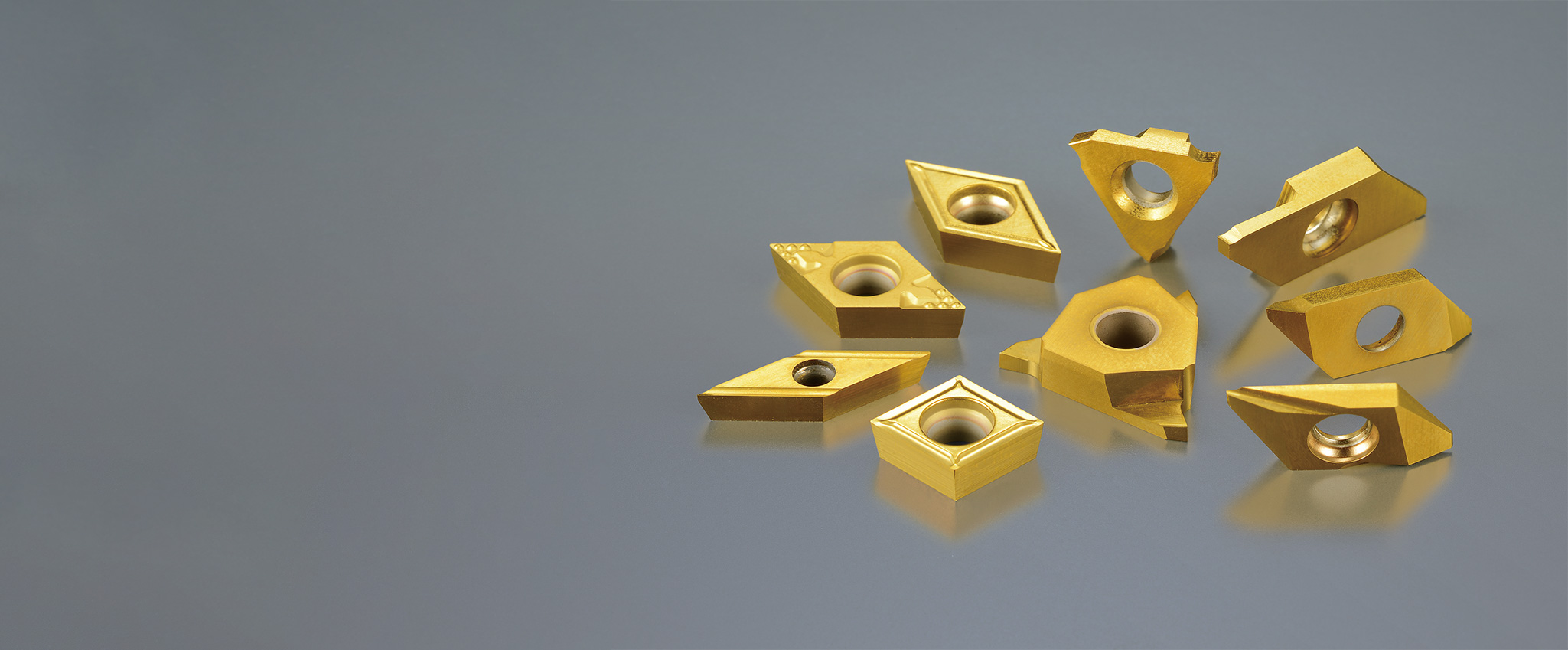

Versatile grade with excellent adhesion resistance | Carbide grade for Swiss CNC lathes

Versatile grade with excellent adhesion resistance | Carbide grade for Swiss CNC lathes

Best selling grade for Swiss -type lathes

Excellent adhesion resistance and workpiece dimensional stability

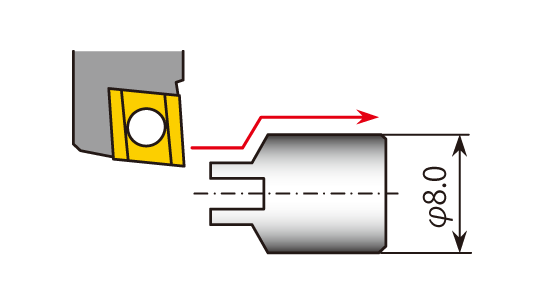

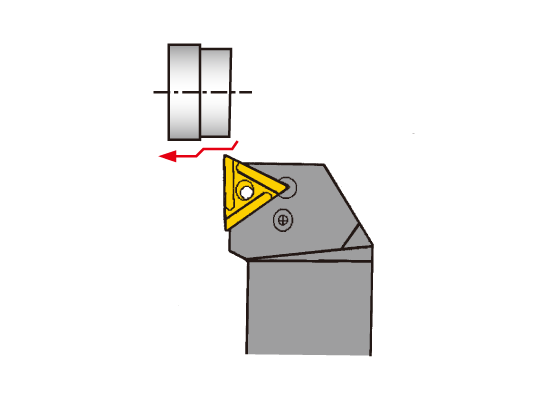

Ideal for high-precision, small diameter parts

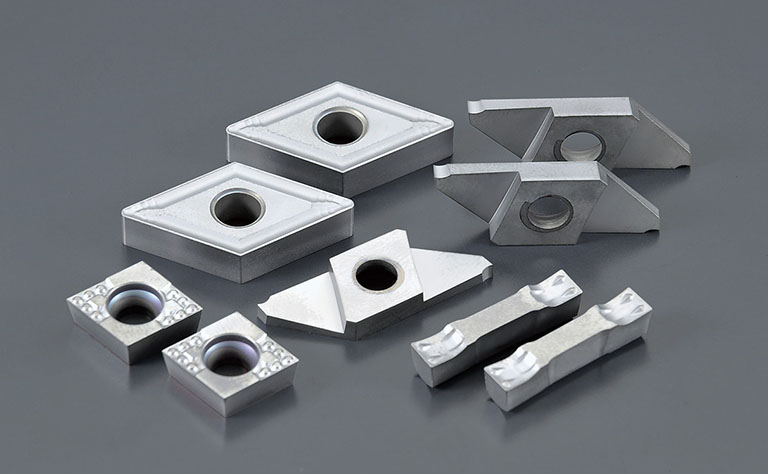

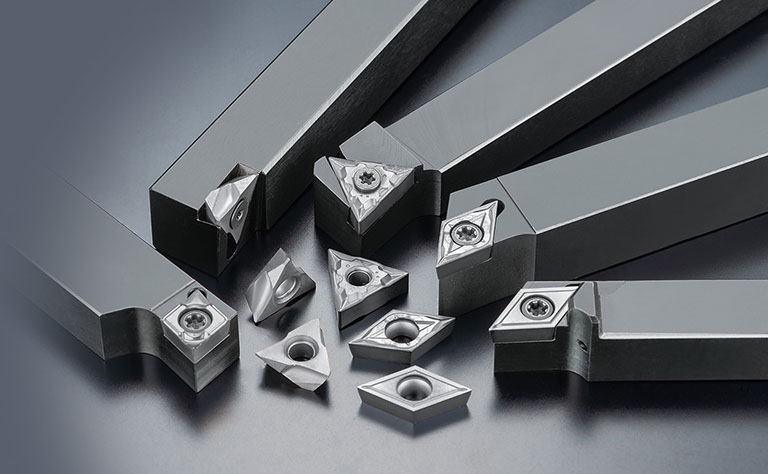

Wide variety of cutting tools for swiss lathe applications

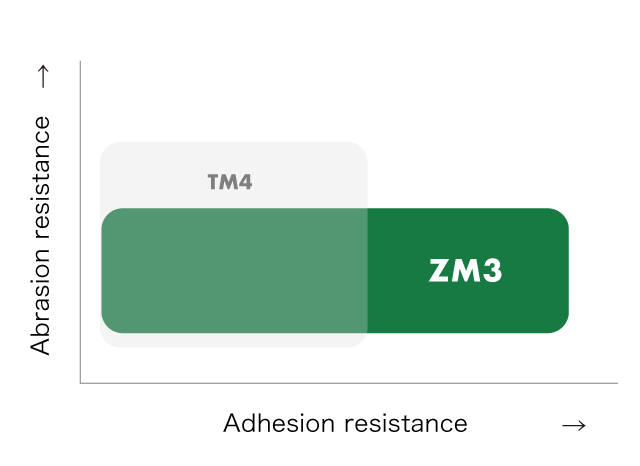

Features

- Strong coating adhesion to substrate helps stabilize workpiece dimensions

- The PVD TiN coating exhibits exceptional adhesion resistance

Tooling application

Wide range of work materials

Front turning / Back turning / Grooving / Cut off / ID boring

ZM3 grade recommendation

Case study

| Electronic component | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| ZM3 | 1,300 pcs / corner |

| Competitor’s PVD coated carbide | 1,000 pcs / corner |

ZM3 was able to equal the surface finish while increasing tool life by 1.3 times that of the competition.

ZM3's obtained a stable performance and long tool life due to the coatings adhesion resistance.

| Case | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| ZM3 | 6,000 pcs / corner and more |

| Competitor’s PVD coated carbide |

|

ZM3 achieved 40 times the tool life compared to the competition with outstanding adhesion resistance and part dimensional consistency.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

AM3 chipbreakerFor front turning operations | Swiss CNC Lathes

Molded chipbreaker with a balance of cutting edge strength and chip control

-

QM3Carbon steel / Alloy steel machining | Carbide grade for Swiss CNC lathes

Amazing wear resistance, fracture resistance for wide speed range. Stable machining in demanding applications.

-

ST4Best grade for machining stainless steel | Carbide grade for Swiss CNC lathes

Having issues machining stainless steel ? - Problem solved

-

DS-ACH holder seriesFor front turning operations | Swiss CNC Lathes

Designed to easily adjust the cutting edge height in machines without Y2 axis capability

Useful information

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining

The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining

Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining "Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab

"Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab

Warning: include(/home/ntk-cuttingtools/www/home2/uk/products/cnc/zm3/../../../../assets/_inc/column.html): failed to open stream: No such file or directory in /home/ntk-cuttingtools/www/home2/uk/products/cnc/zm3/index.html on line 444

Warning: include(): Failed opening '/home/ntk-cuttingtools/www/home2/uk/products/cnc/zm3/../../../../assets/_inc/column.html' for inclusion (include_path='.:/usr/local/php/7.4/lib/php') in /home/ntk-cuttingtools/www/home2/uk/products/cnc/zm3/index.html on line 444