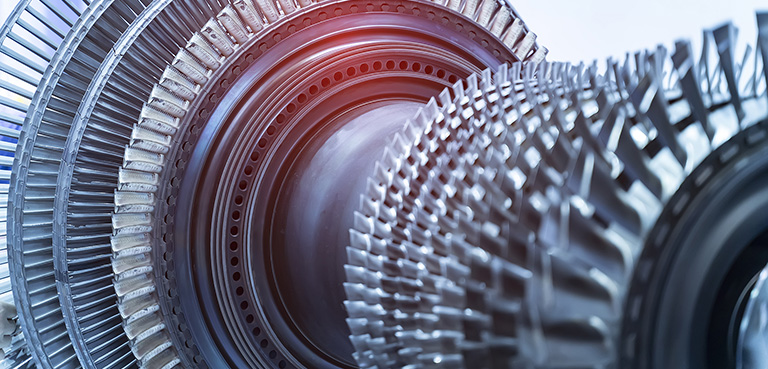

Continuous machining of gray cast iron| Alumina ceramic (White ceramics)

Continuous machining of gray cast iron| Alumina ceramic (White ceramics)

First recommendation for finishing gray cast iron

High-speed performance is achievable with the thermally and chemically stable alumina ceramic blend

Effective machining at speeds up to 2300 SFM

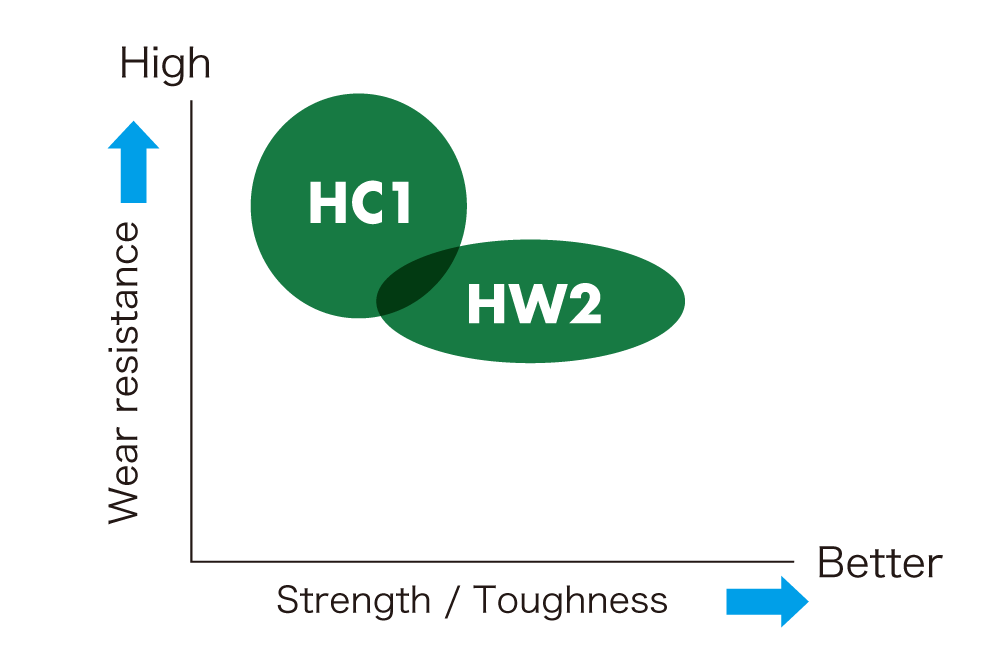

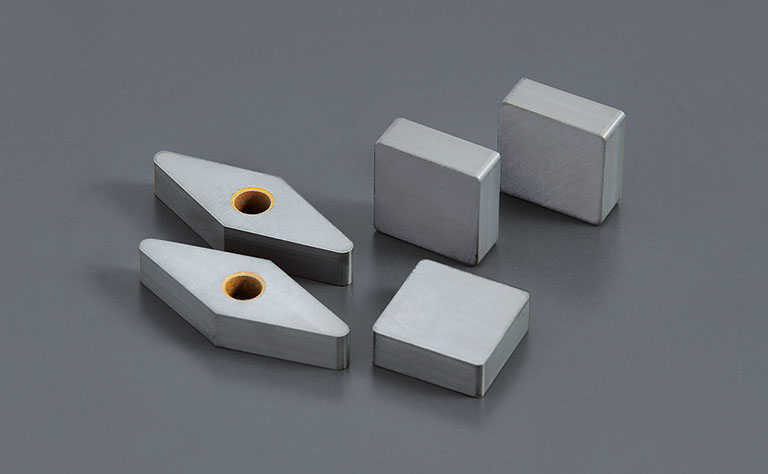

Features

- Best grade for high-speed finishing

- HC1 grade - best wear resistance

- HW2 grade - outstanding fracture resistance

Tooling application

Gray cast iron

Finish Turning

Grade characteristics

Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Machining | Cutting speed (SFM) | cylinder liners | Feed(IPR) | DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|---|

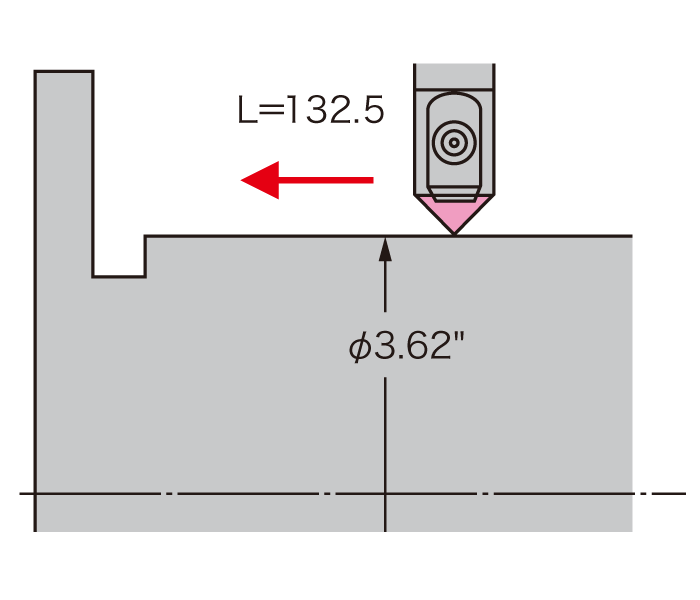

| HC1 | Gray cast iron | Turning | Finish turning of Gray cast iron | 1200 -2300 | 600 - 1800 | .004 - .016 | - .080 | DRY |

| HW2 | Roughing to semi-interrupted finishing of gray cast Roughing to finishing of cylinder liners |

1200 - 2100 |

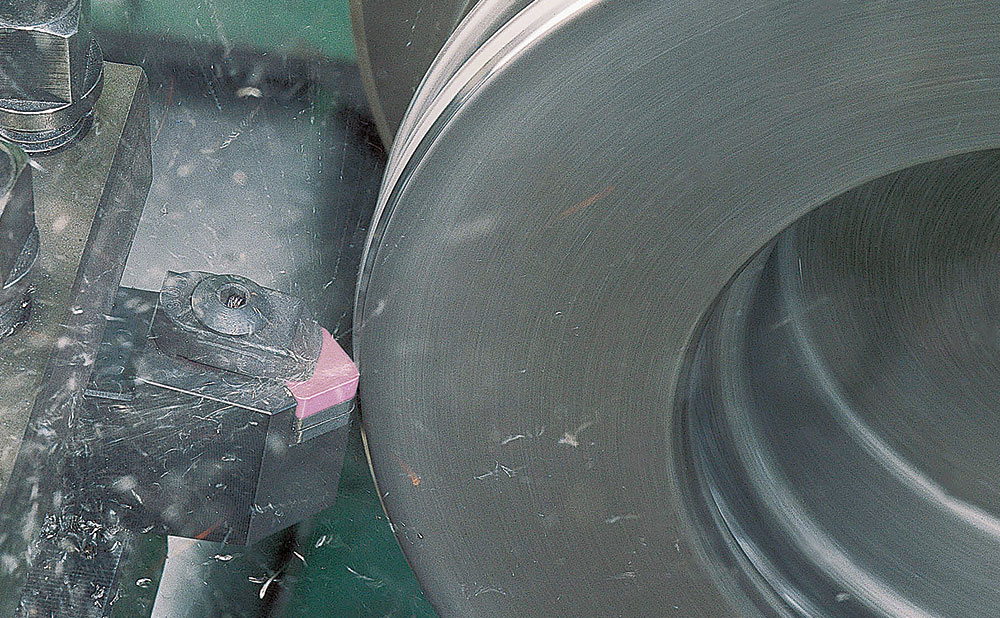

Gray cast iron finishing application

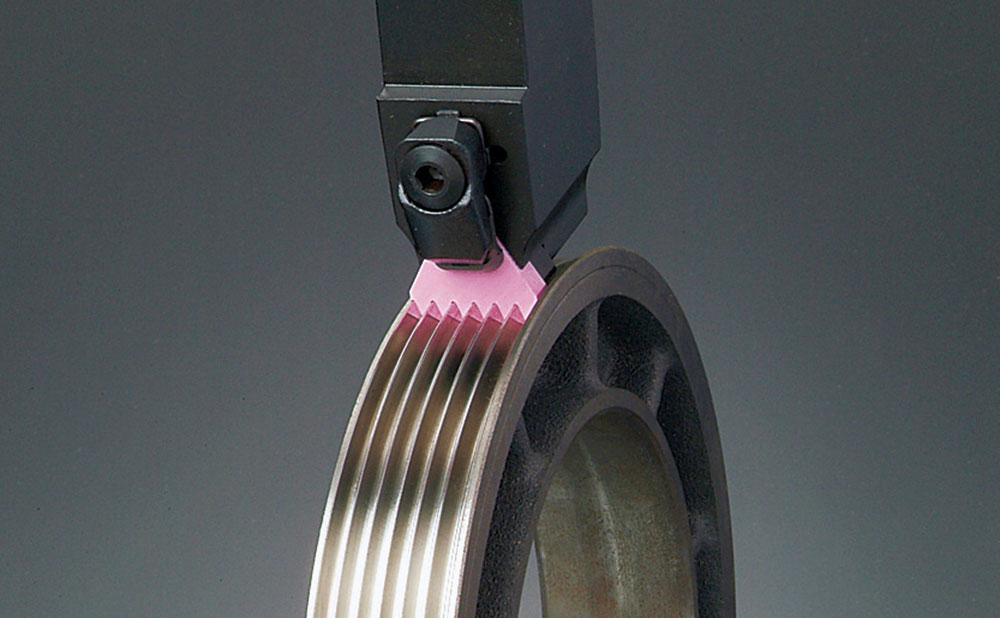

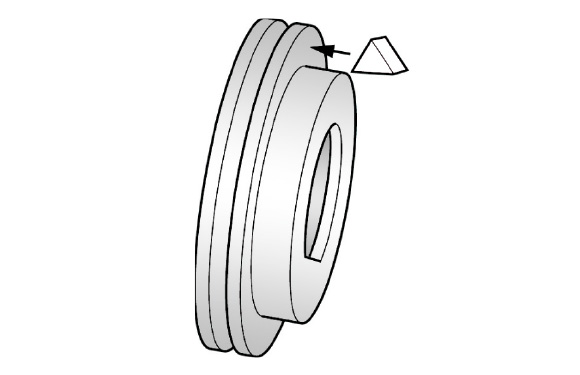

Special inserts for Poly V pulley machining

Case study

| Disk brake | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| HC1 | 130 pcs / corner |

|

| Competitor's black ceramic | 60 pcs / corner |

|

- HC1 doubled the tool life of the competitor's black ceramic.

| Cylinder liner | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| HW2 | 70 pcs / corner |

|

| Competitor's ceramic | 30 pcs / corner |

|

- HW2 doubled the tool life and achieved superior surface finishes on the part compared to the competitor's insert.

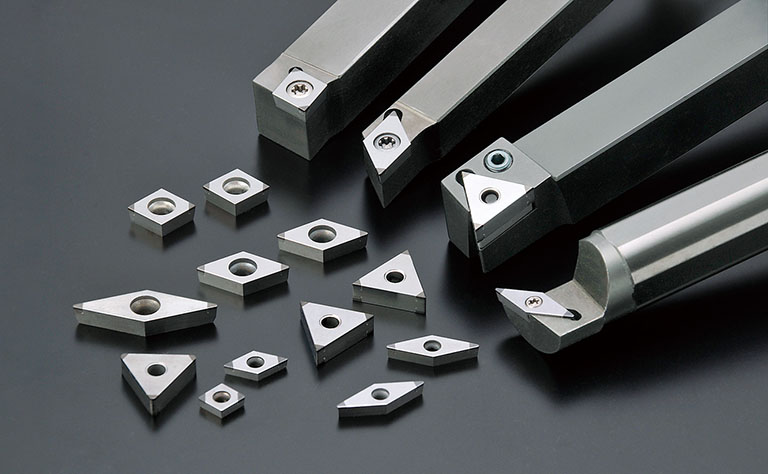

Tool lineup

Other recommended products

-

B23/B30High-speed finishing of gray cast iron| Uncoated CBNs

Best CBN grades for machining gray cast iron

-

SP9Roughing to finishing of ductile cast iron & gray cast iron| Coated Silicon Nitride Ceramic

Covers roughing to finishing operations

-

SX6Exceptional wear resistance for rough machining of gray cast iron| Silicon nitride ceramic

First recommendation for roughing gray cast iron

-

SX9Excellent notch and flank wear resistance when roughing gray cast iron|Sialon ceramic

Ceramic grade with the best fracture resistance

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch