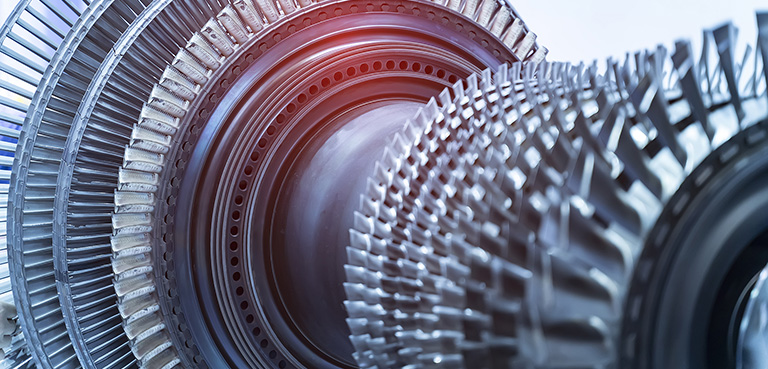

Exceptional wear resistance for rough machining of gray cast iron| Silicon nitride ceramic

Exceptional wear resistance for rough machining of gray cast iron| Silicon nitride ceramic

First recommendation for roughing gray cast iron

Machine gray cast iron at Speeds ~ 3900 SFM

Outstanding boundary wear resistance

Outstanding thermal shock resistance

Product video (Metric ver.)

Features

- Superior tool life during high-speed machining due to its wear resistance

- Excellent thermal shock resistance when turning and milling with coolant

Tooling application

Gray cast iron with scale

Rough Turning / Milling

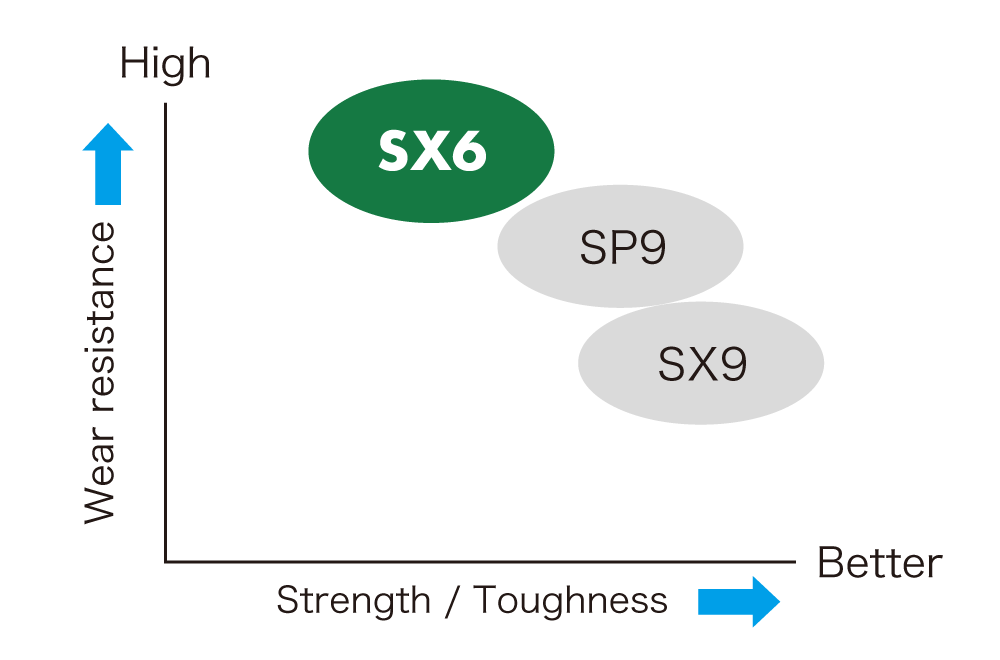

Grade characteristics

Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Machining | Cutting speed (SFM) | Feed (IPR /IPT) | DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|

| SX6 | Gray cast iron | Turning | Roughing with scale, Rough to semi-finish machining | 1500 -3500 | .012 - .025 | - .140 | DRY / WET |

| Milling | 1500 -4200 | .003 - .010 |

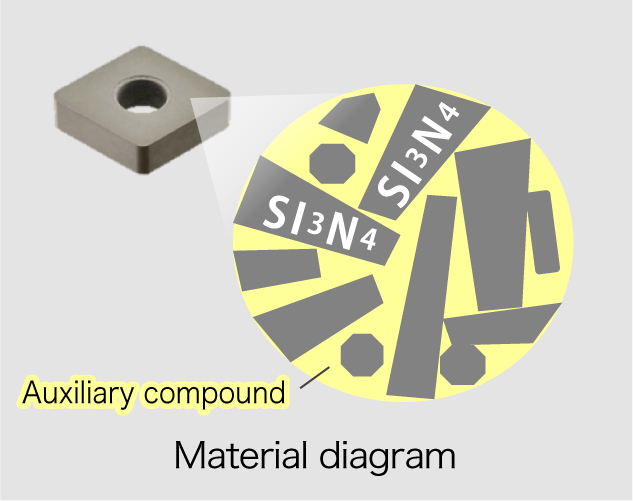

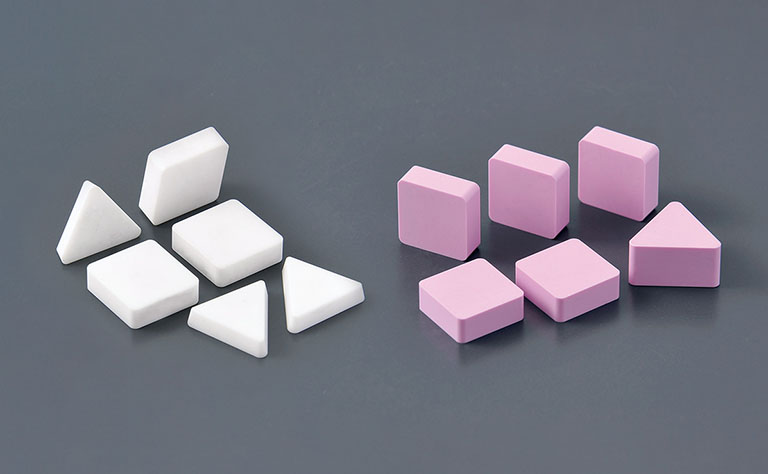

Why is silicon nitride ceramic resistant to chipping?

The main component is silicon nitride(Si3N4), which differs from alumina-based materials in that its particles are needle-like.

The intertwining of the needle-like particles greatly suppresses the progression of cracks caused by impact during cutting and prevents chipping.

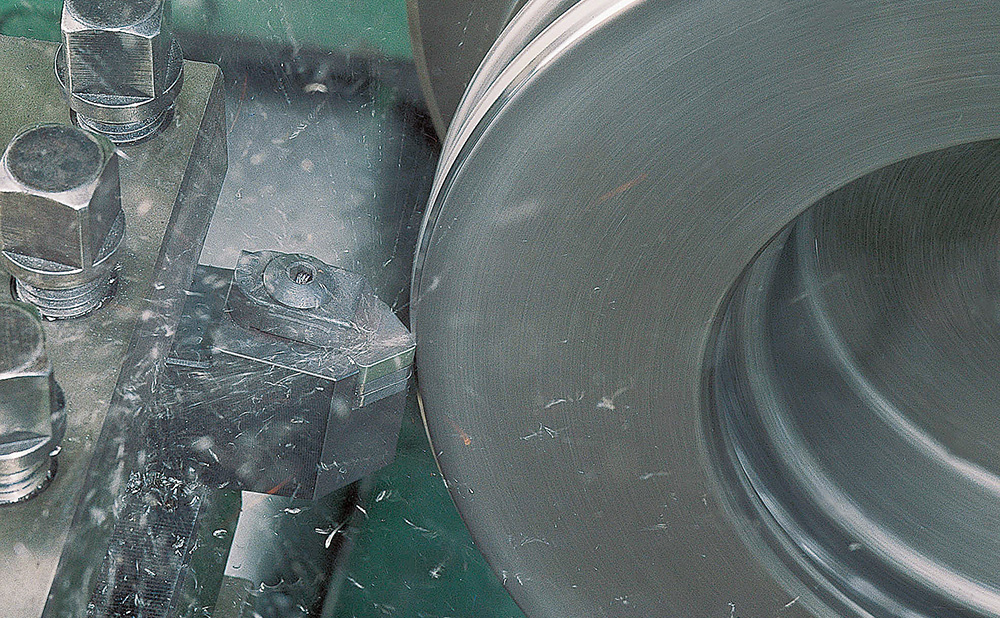

Gray cast iron roughing application

Case study

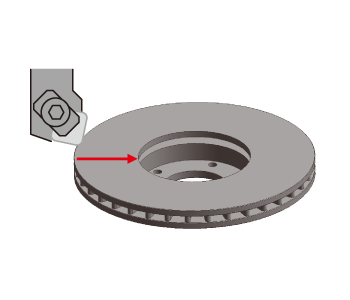

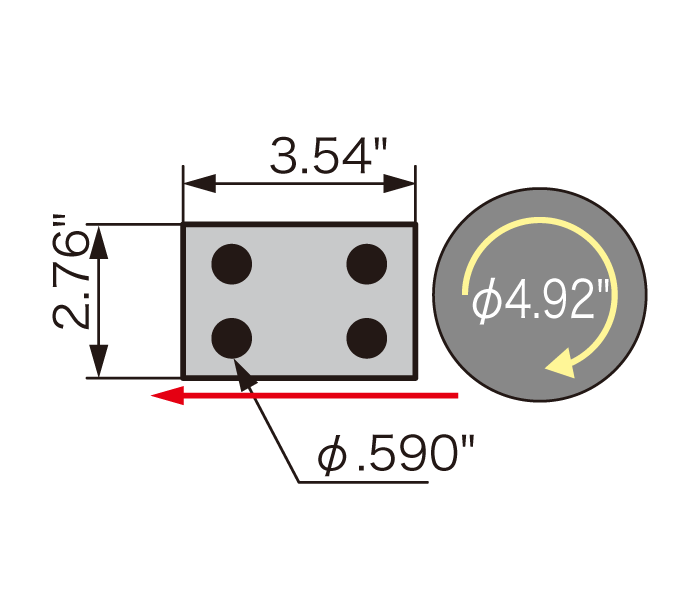

| Brake disc | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| SX6 | 75 pcs / corner |

|

| Competitor's silicon nitride | 50 pcs / corner |

|

- SX6 achieved 1.5 times longer tool life compared to competitor's silicon nitride

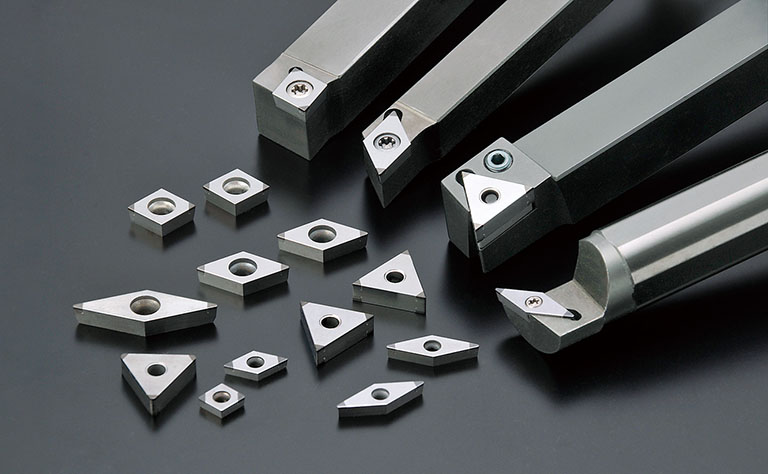

| Milling Application | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

|

||

| SX6 | 360 pcs / corner |

|

| Competitor's carbide inserts | 260 pcs / corner |

|

- High-speed milling with ceramic significantly reduced cycle time compared to the current carbide inserts. (Single pass process went from 40 min. down to 15min.)

SX6 achieved 1.4 times more tool life.

Tooling costs are reduced by utilizing negative inserts, increasing the number of corners.

Tool lineup

Other recommended products

-

SX9Excellent notch and flank wear resistance when roughing gray cast iron|Sialon ceramic

Ceramic grade with the best fracture resistance

-

HC1/HW2Continuous machining of gray cast iron| Alumina ceramic (White ceramics)

First recommendation for finishing gray cast iron

-

B23/B30High-speed finishing of gray cast iron| Uncoated CBNs

Best CBN grades for machining gray cast iron

-

CP1Roughing gray cast & ductile cast iron / CVD coated carbide

CVD coated carbide grade ideal for roughing

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch