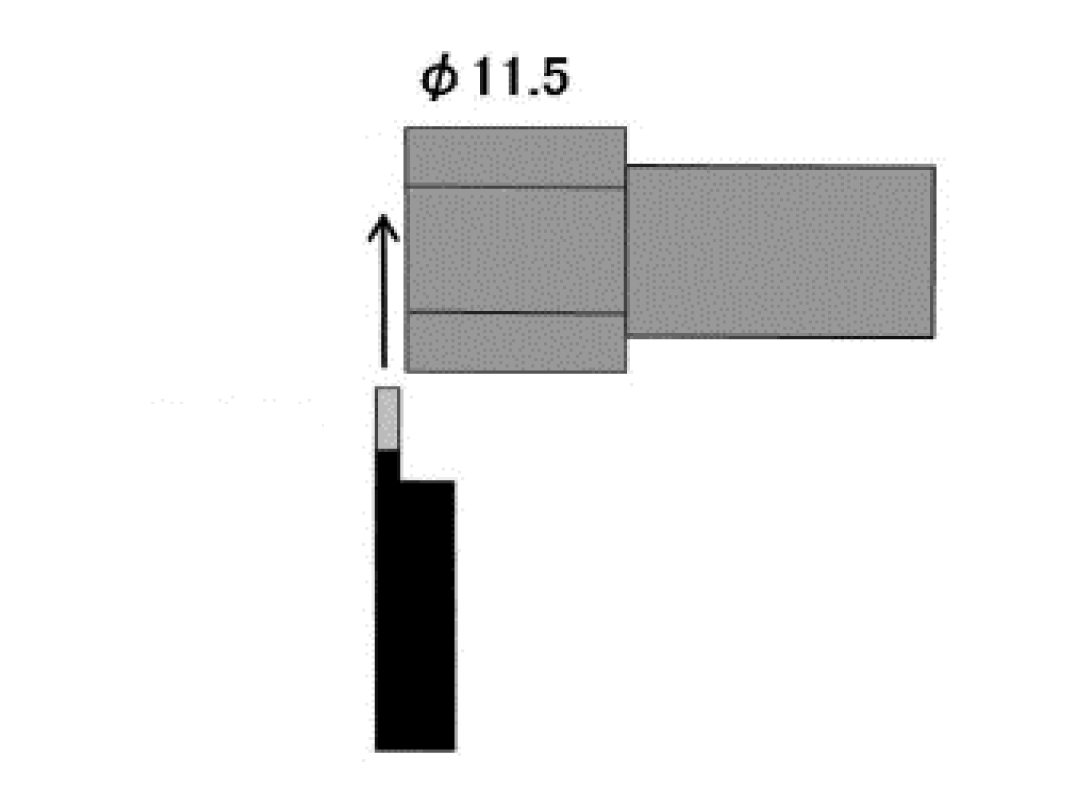

Cut-off operations for diameters up to 34mm 1.339” | Swiss CNC Lathes

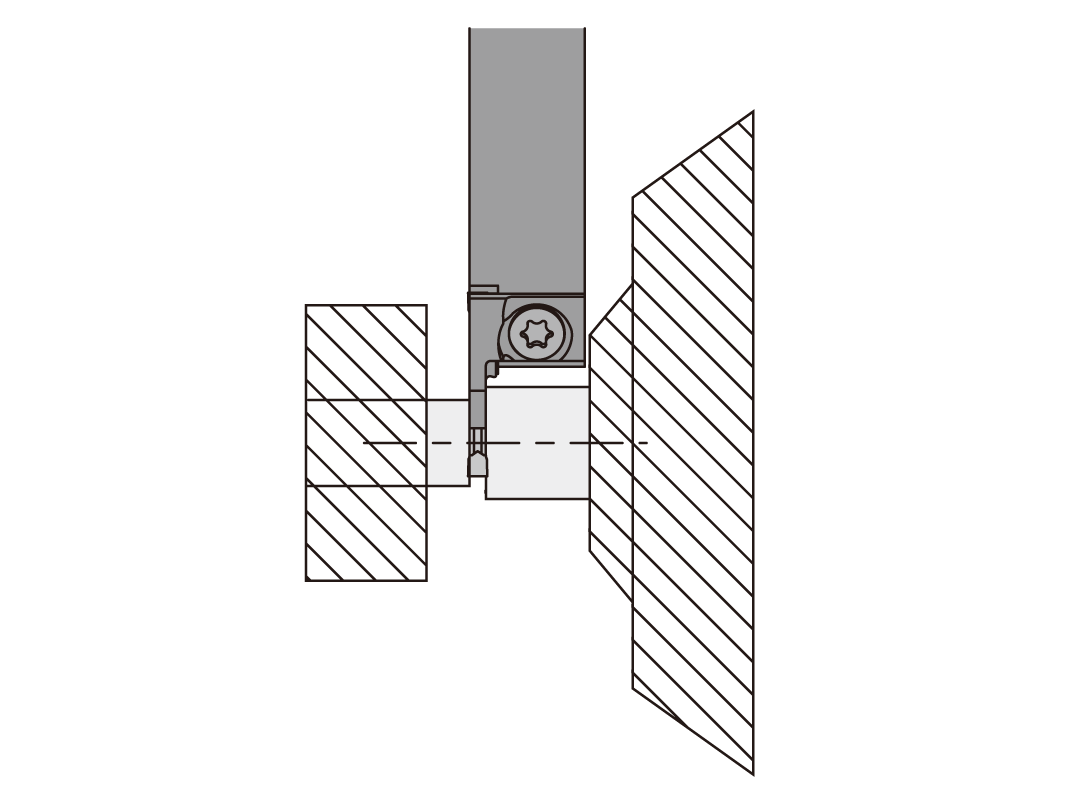

Swiss CNC lathe cut-off operation

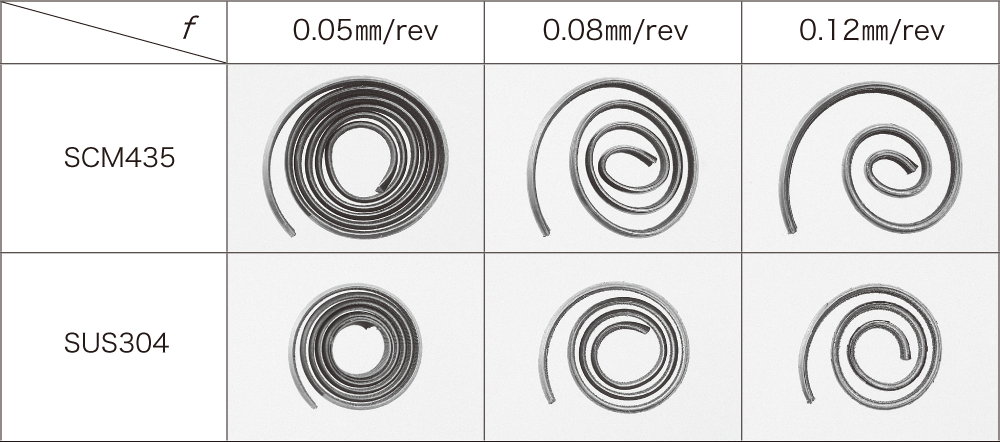

Evacuates chips to eliminate chip tangling

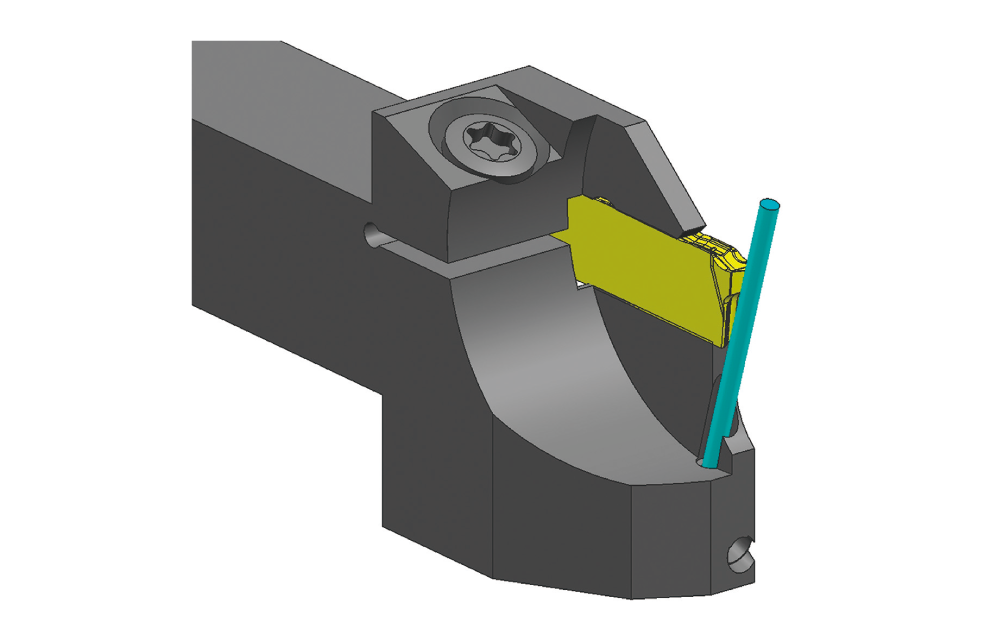

Coolant is directed at the cutting edge which greatly improves insert tool life.

| Coated grade | Material | Operation type | Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/rev) Feed (IPR) | Maximum cut-off diamter |

|---|---|---|---|---|---|

| ST4 | Stainless | Cut off | 30 – 90 80 – 250 | 0.03 – 0.12 .0012 – .008 | ⌀34 ⌀1.339” |

| QM3 | Alloy steel / carbon steel / hardened material | 50 – 130 100 – 300 | 0.04 – 0.15 .0016 – .005 | ||

| DM4 | Difficult-to-cut material / titanium alloy / high temp alloys | 50 – 100 100 – 230 | 0.03 – 0.15 .0012 – .005 | ||

| TM4 | Non-ferrous / aluminum / plastic / general purpose | 80 – 200 160 – 480 | 0.05 – 0.2 .002 – .006 |

| Shaft | |

|---|---|

|

|

|

|

|

|

|

|

| QM3 |

6,000 pcs / corner

|

| Competitor’s PVD coated |

3,000 pcs / corner

|

Cut Duo achieved 2x the tool life and generated high quality surface finishes compared to the competitor’s PVD coated insert

| Valve parts | |

|---|---|

|

|

|

|

|

|

|

|

| QM3 |

230 pcs / corner

|

| Competitor’s molded chipbreaker (PVD coated carbide) |

100 pcs / corner

|

Cut Duo achieved 2.3 x more tool life compared to competitor’s insert with chipbreaker. Its sharp cutting edge greatly improved the surface finish of the part

For more information about this product, visit our online e-catalog, or download the catalog/product report