For small diameter parts | New HiPIMS Coating

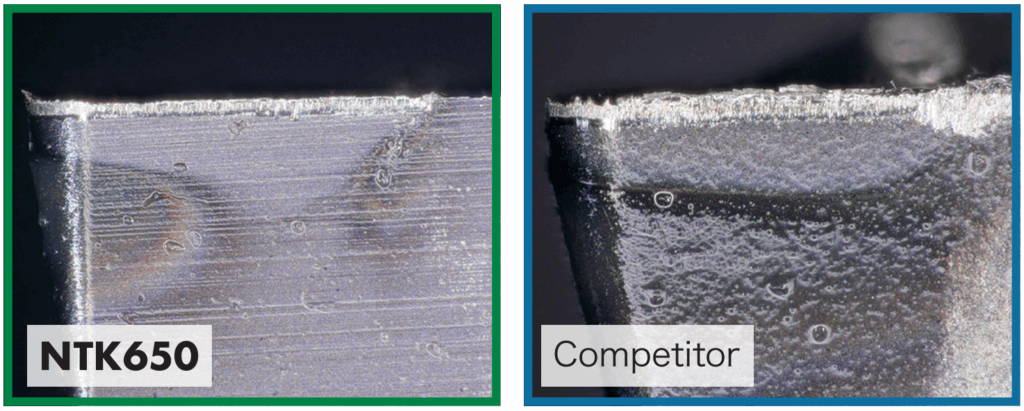

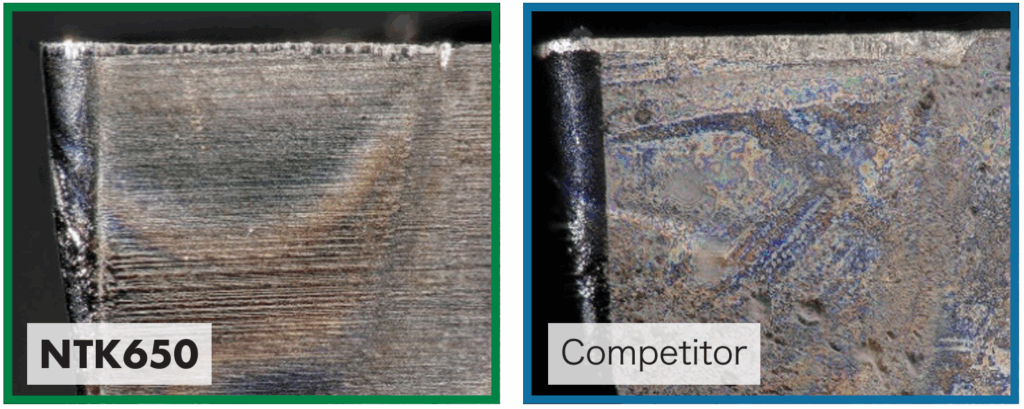

NTK650 doubled the wear resistance comparing with competitor

Shape: DCGT11T302, vc=50m/min, f=0.05mm/rev, ap=1.0mm, WET

NTK650 doubled the wear resistance comparing with competitor

Shape: DCGT11T302, vc=160m/min, f=0.05mm/rev, ap=1.0mm, WET

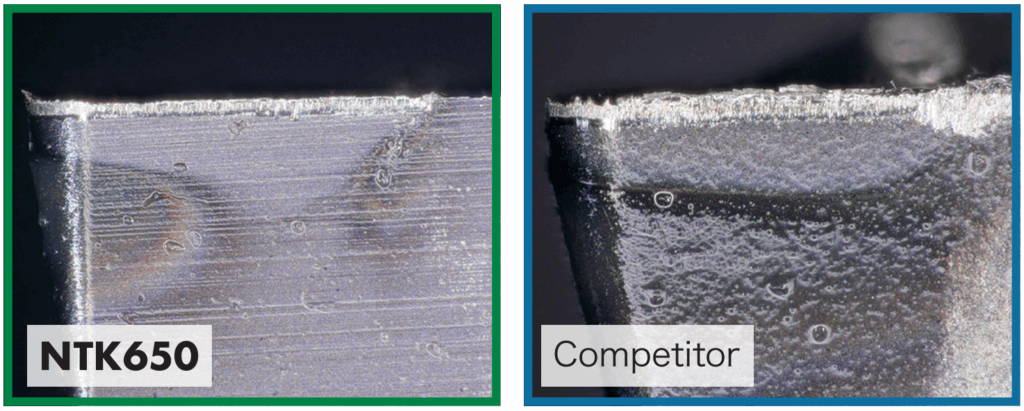

Improved surface roughness near the hole and Doubling the tool life

Shape:DCGT11T301, vc=78m/min, f=0.085mm/rev, ap=1.5mm, WET

| Grade | Work material | Operation type | Cutting parameters | ||

|---|---|---|---|---|---|

| Cutting Speed (m/min) Cutting Speed (sfm) | Feed (mm/rev) Feed (ipr) | Depth of cut (mm) Depth of cut (inch) | |||

| NTK650 | Inconel | Front turning | 30 – 60 100 – 200 | 0.03 – 0.07 .0012 – .0028 | 0.5 – 1.5 .019 – .059 |

| Hastelloy | Front turning | 50 – 100 160 – 330 | 0.03 – 0.07 .0012 – .0028 | 0.5 – 1.5 .019 – .059 | |

| Semiconductor part | |

|---|---|

|

|

|

|

|

|

|

|

| NTK650 |

400 pcs / corner

|

| Conventional tool (Carbide Coated) |

|

NTK650 suppressed the occurrence of streaks and achieved 4 times longer tool life.

| Joints for Power Plant | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| NTK650 |

420 pcs / corner

|

| Conventional tool (Carbide Coated) |

210 pcs / corner

|

NTK650 achieves stable machining accuracy, reduces inspection time, and achieves twice toollife with its stable surface finish.

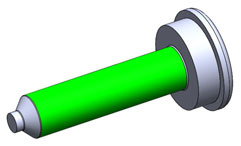

| Pin Parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| NTK650 |

9,800 pcs / edge

|

| Conventional tool (PVD carbide) |

5,500 pcs / edge

|

NTK650 achieved 1.8 times tool life.

| Bolt | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| NTK650 |

500 pcs / edge

|

| Conventional tool (PVD carbide) | 100 pcs/edge |

NTK 650 grade provides a better surface finish and excellent anti-adhesion properties, reducing wear caused by built-up edge. As a result, it achieved 5 times longer tool life and stable machining.

For more information about this product, visit our online e-catalog, or download the catalog/product report