Back turning | Swiss CNC Lathes

Swiss CNC lathe back turning

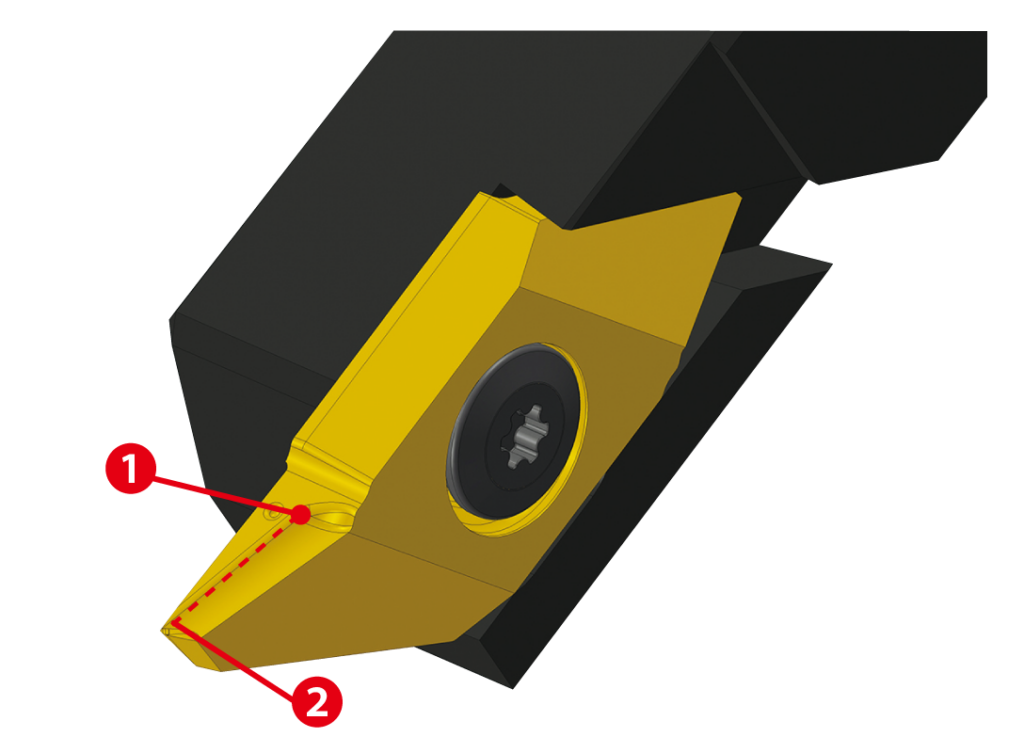

① Prevents the chip from damaging the shoulder feature on the part

② Wiper flat feature generates excellent surface finish

| Coated grade | Material | Operation type | Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/rev) Feed (IPR) | DOC (mm) DOC (inch) |

|---|---|---|---|---|---|

| ST4 | Stainless | Back turning | 50 – 120 100 – 275 | X direction:

0.01-0.03

.0004 – .0012

Z direction: 0.03 – 0.04 .0008 – .0016 |

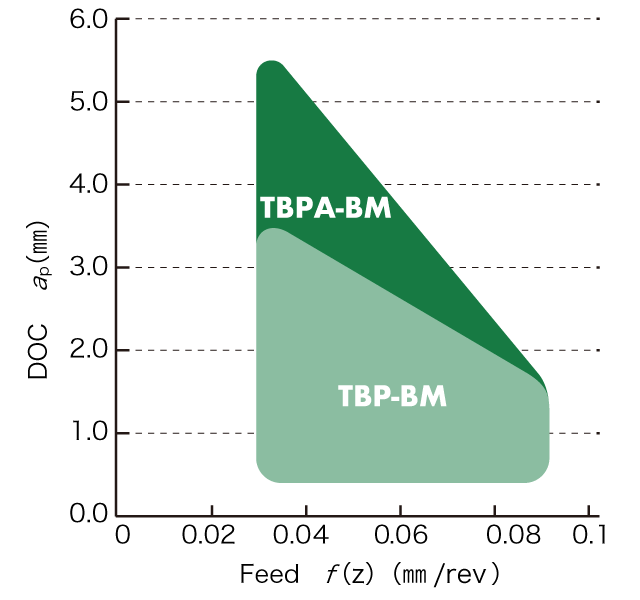

TBP-BM :

0.5-3.5

.020 – .209

TBPA-BM : 0.5-5.5 .020 – .256 |

| DM4 | Difficult-to-cut material / titanium alloy / Alloy steel / carbon steel / hardened material / high temp alloys | 30 -120 75 – 500 | X direction:

0.01-0.03

.0004 – .0016

Z direction: 0.03 – 0.08 .0008 – .0031 |

||

| TM4 | Non-ferrous / aluminum / plastic / general purpose | 50 – 180 150 – 500 | X direction:

0.01-0.03

.0004 – .0016

Z direction: 0.03 – 0.08 .0008 – .0031 |

| Stud | |

|---|---|

|

|

|

|

|

|

|

|

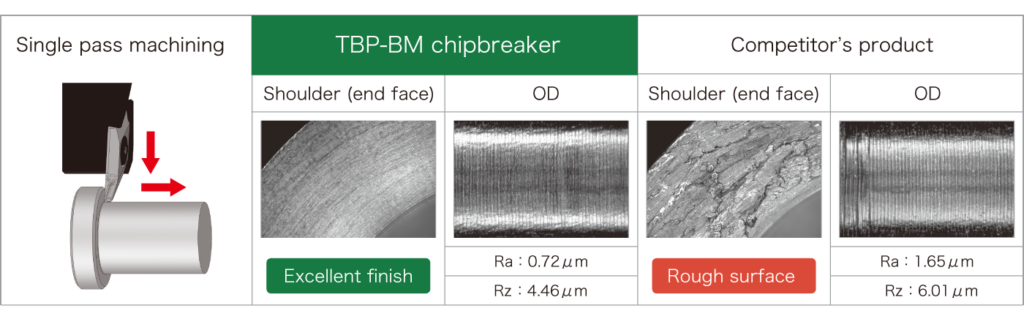

| TBP-BM | ①1 pass machining * no extra operations required |

| Competitor’s product | ①Roughing – grooving operations ②Finishing – back turn operation |

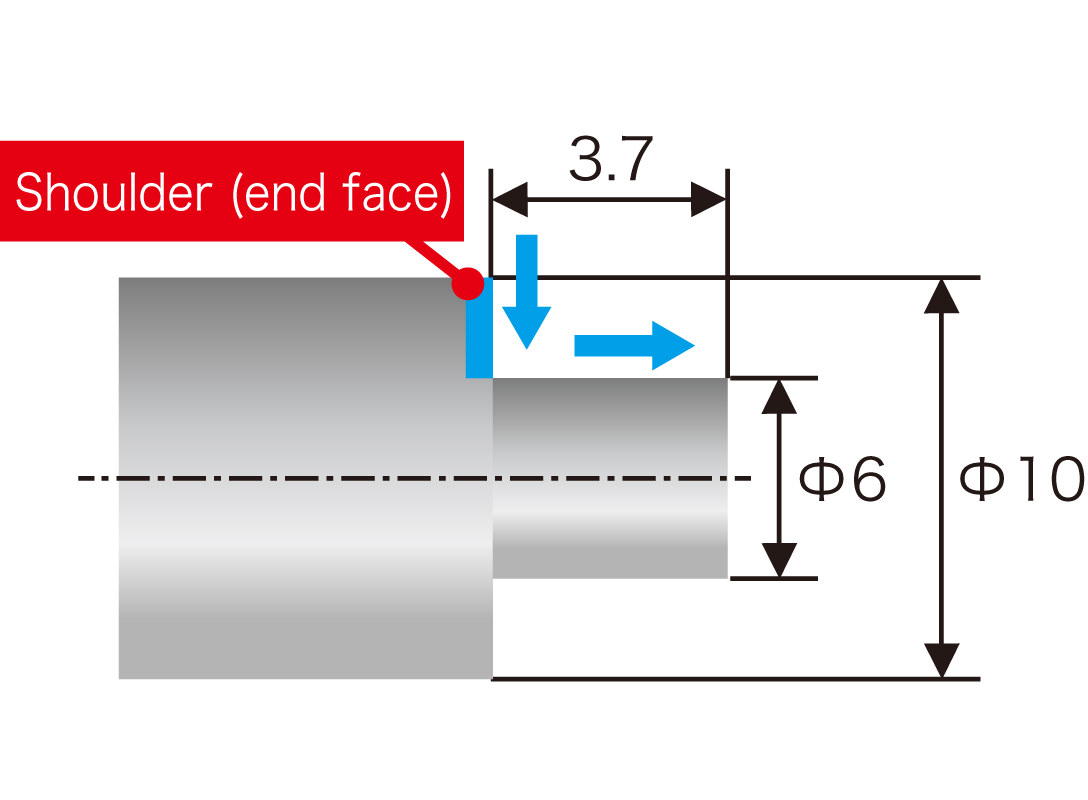

The current process required 2 steps to complete the part feature.

NTK’s BM chipbreaker achieved shortened cycle time with a single pass operation .

High quality finish on the OD and shoulder due to the chipbreaker design which evacuates chips away from the part

For more information about this product, visit our online e-catalog, or download the catalog/product report