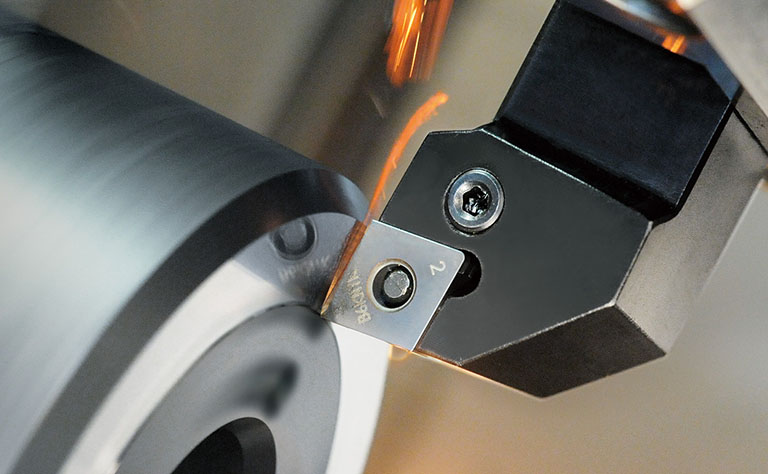

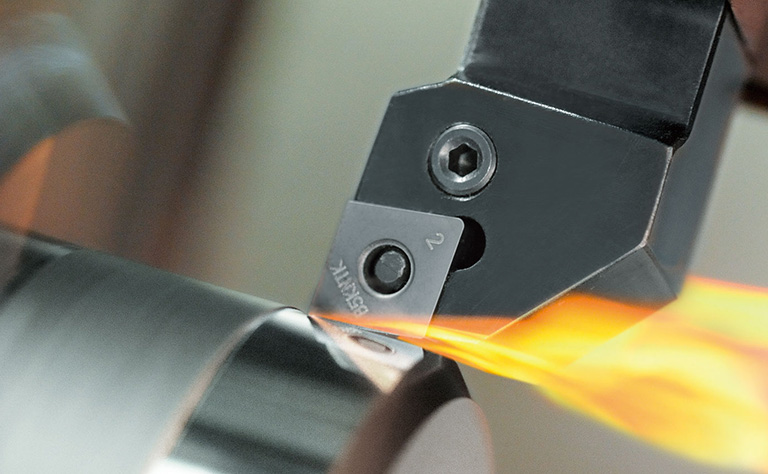

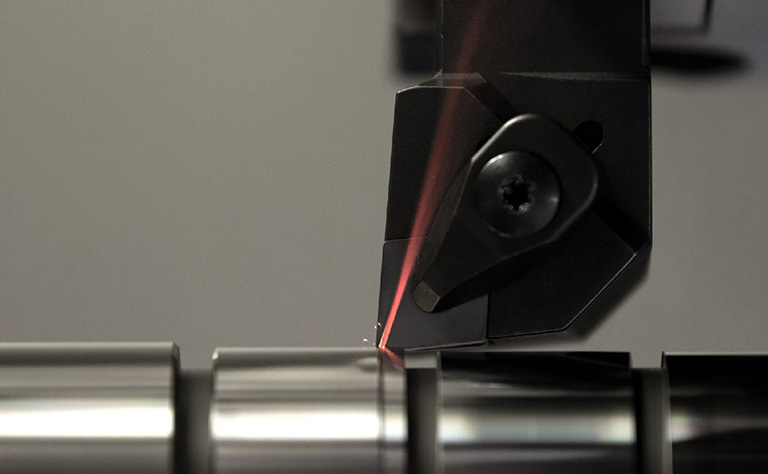

For heavy interrupted machining | CBN for machining hardened material

For heavy interrupted machining | CBN for machining hardened material

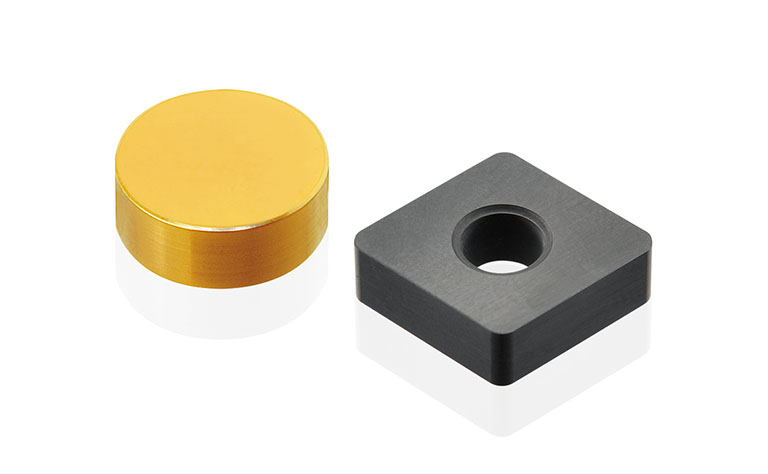

High performance, low cost CBN

Recommended for heavy interrupted cuts

Excellent toughness and stable machining

Ideal for hardened materials of HRC 55 or higher

Product video

Features

- Exceptional toughness due to a special TiN binder blended with the CBN

- Chipping resistance achieves stable machining through heavy interruptions

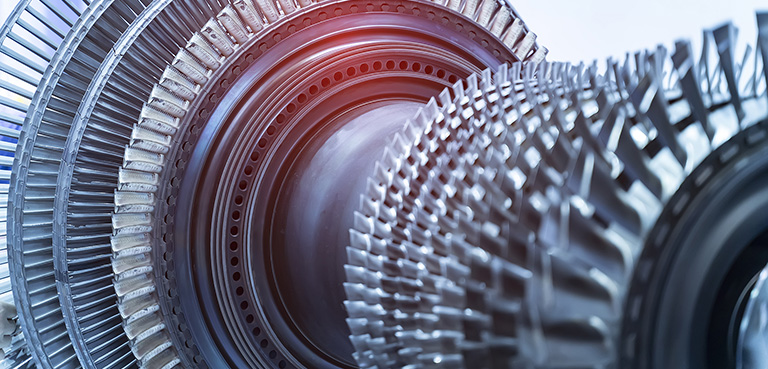

Tooling application

Heavy interrupted machining of hardened materials of HRC55 or above

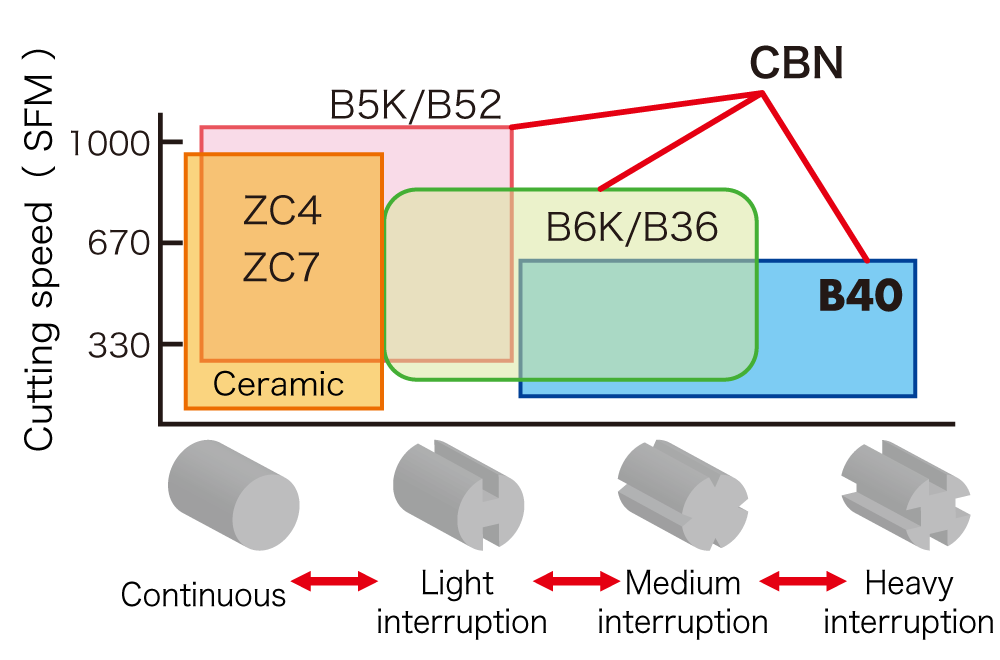

Grade application chart

Cutting conditions

Scroll the table →

| ●1st Recommendation 〇2nd Recommendation |

||||||||

| Grade | Material | Operation type | Machining | Cutting speed (SFM) | Feed(IPR) | DOC(inch) | DRY | WET |

|---|---|---|---|---|---|---|---|---|

| B40 | Hardened material (HRC55 or above) | Turning Heavy interrupted machining | Finishing | 100 - 500 | ~ .004 | .004 - .040 | ● | 〇 |

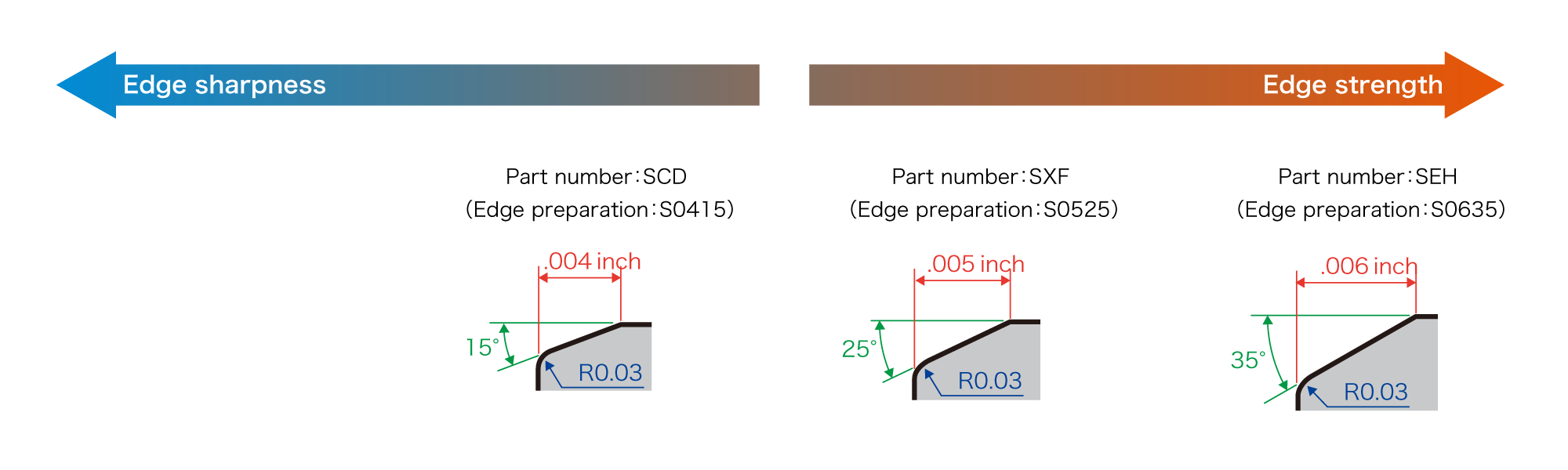

Edge preparations

Scroll the table →

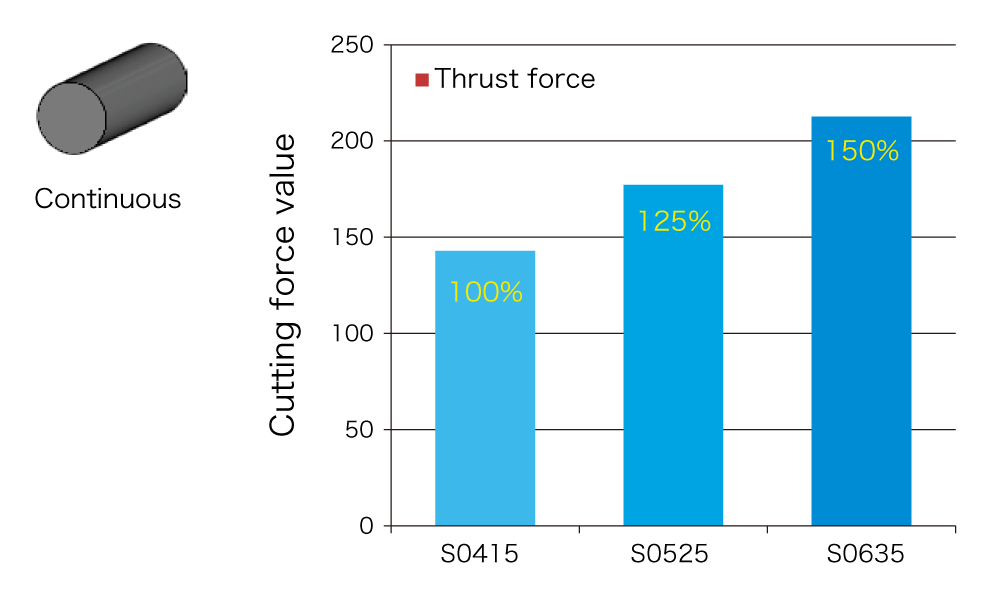

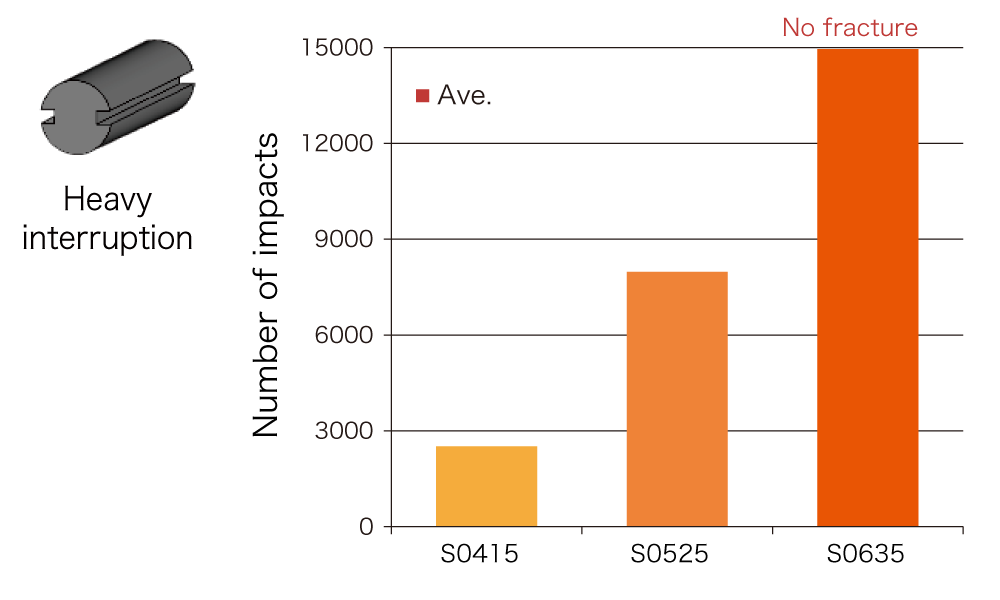

Performance comparison by edge preparation

- As the edge preparation increases the tool pressure on the insert increases.

- [ Cutting conditions ]

- SCM415(HRC63-65) 670 SFM .004 IPR .008 DOC DRY

- [ Insert ]

- TNGA160408

- There is a direct correlation between an increase in the edge preparation and improvement of insert fracture resistance.

- [ Cutting conditions ]

- SCM415(HRC63-65) 250 SFM .004 IPR .012 DOC DRY

- [ Insert ]

- TNGA160408

Case study

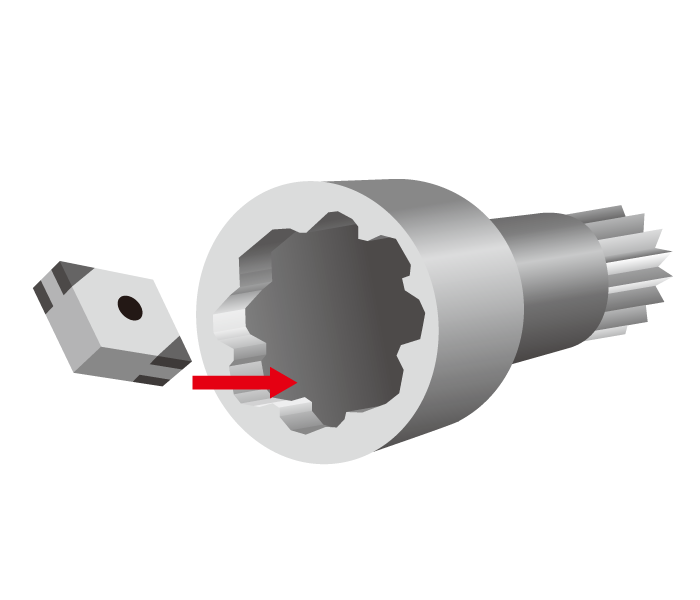

| Interrupted ID boring of automotive parts | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| B40 | 2,300 pcs / corner |

|

| Competitor's CBN | 1,500 pcs / corner |

|

- B40 achieved longer tool life through the heavy interruptions without chipping

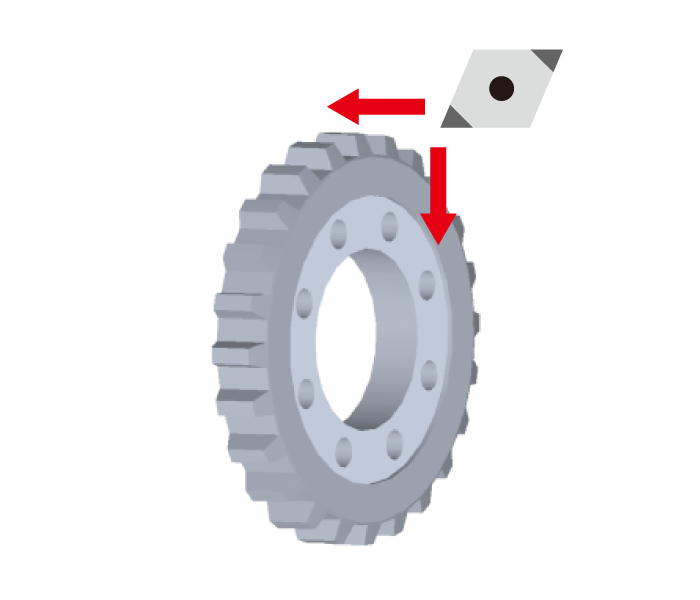

| Interrupted OD turning gear part coupling | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| B40 | 400 pcs / corner |

|

| Competitor's CBN | 100 pcs / corner |

|

- Competitor's CBN had edge damage due to interruptions. B40's excellent toughness achieved 4 times longer tool life.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

B6K/B36For light to medium interrupted machining | CBN for machining hardened material

High performance, low cost CBN

-

B5K/B52For continuous-light interruption machining | CBN for machining hardened material

High performance, low cost, versatile CBN

-

NTK450For Hard Turning in Continuous Cuts | NTK CeramiX

The ultimate ceramic grade for finishing hardened materials -" NTK CeramiX "

-

ZC7/ZC4For continuous machining | Ceramic for machining materials 30 - 70 HRC

Significant cost savings for high hardness materials

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch