For machining heat-resistant alloys | Ceramic

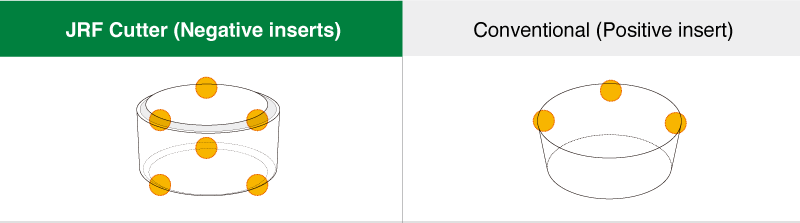

🟡 Available corners

| Cutter body dia.: ø 16 mm .63 inches (Bottom machining Dia.: ø 9.65 mm .38 inches ) | |

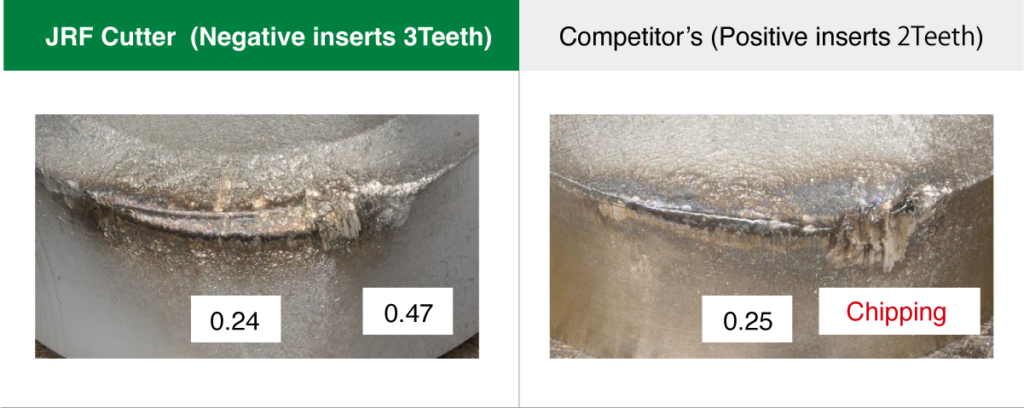

| Work material | Inconel718 |

| Cutting speed |

606 m/min

1988.2 ft/min

(20000rpm) |

| Feed | 0.1 mm/t .004 in/t |

| DOC | 1 mm .04 in |

| Removal volume per tooth | 16.66 cc 1.017 ci |

※Since the new NTK cutter has three inserts, the total volume removed is 1.5 times that of competitor’s.

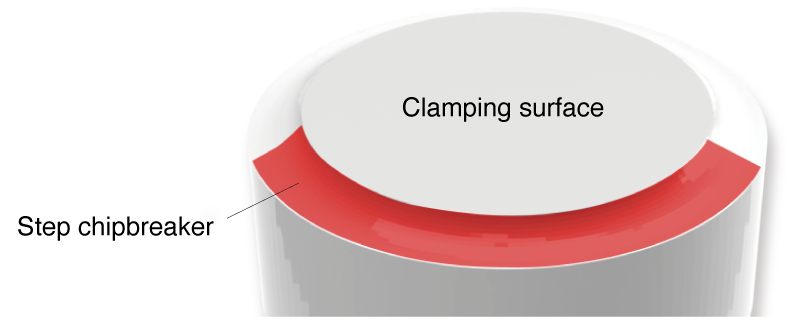

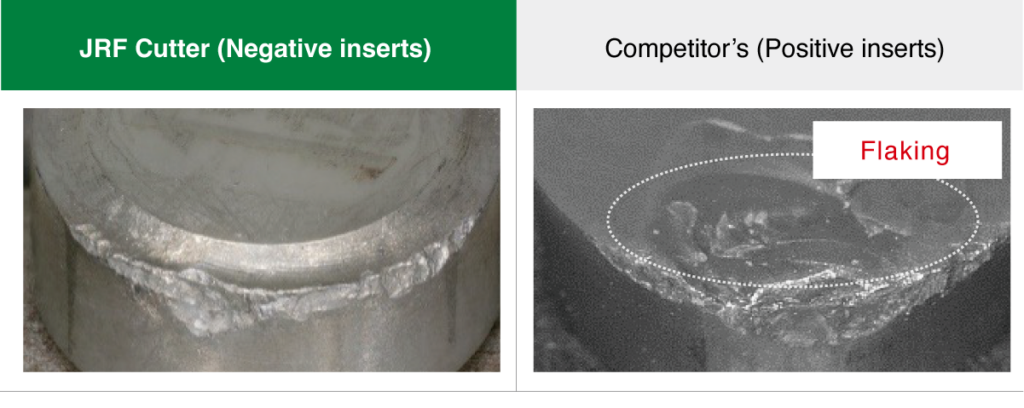

A step breaker with the cutting edge lowered from the clamping surface suppresses flaking.

| Grade | Material | Operation type | Cutting speed | Feed | DOC | Coolant |

|---|---|---|---|---|---|---|

| SX3 / SX9 | Heat resistant alloys | Milling | 400 – 700 ‒ 1000 m/min 1312.3 – 2296.6 – 3280.8 ft/min | 0.08 – 0.10 – 0.12 mm/t .003 – .004 – .005 in/t | 1 mm .04 inches | DRY |

※Since the new NTK cutter has three inserts, the total volume removed is 1.5 times that of competitor’s.

| Cutter Item number | Cutting edge dia | Tooth | Allowable rotation speed (min-1) |

|---|---|---|---|

| JRFMH016E160R03 | 16 | 3 | 20,000 |

| JRFIH0625E0625R03 | 15.875 | ||

| JRFMH020E200R03 | 20 | 17,500 | |

| JRFIH075E075R03 | 19.05 | ||

| JRFMH025E250R04 | 25 | 4 | 15,000 |

| JRFIH100E100R04 | 25.4 | ||

| JRFMH025E250R03 | 25 | 3 | 15,000 |

| JRFIH100E100R03 | 25.4 | ||

| JRFMH032E320R05 | 32 | 5 | 12,500 |

| JRFIH125E125R05 | 31.75 | ||

| JRFMH032E320R04 | 32 | 4 | 12,500 |

| JRFIH125E125R04 | 31.75 | ||

| JRFMH032E320R03 | 32 | 3 | 12,500 |

| JRFIH125E125R03 | 31.75 |

| Waspaloy(Combustion case) | ||

|---|---|---|

| JRF Cutter | Competitor’s | |

| Grade | SX9 | SX9 (RP) |

| Tooth | 5 ø32 mm ø1.26 inches | 3 ø32 mm ø1.26 inches |

| Vc | 564 m/min 1850.4 ft/min | 564 m/min 1850.4 ft/min |

| Fz | 0.05 mm/t .002 in/t | 0.05 mm/t .002 in/t |

| F | 2000 mm/min 78.74 in/min | 1200 mm/min 47.24 in/min |

| DOC ap | 1 mm .04 inches | 1 mm .04 inches |

| Tool life | 2 Pass | 1 Pass |

| Corner | 8 | 5 |

|  |

| Cost Productivity | |

| NTK | 68% ← |

|---|---|

| Competitor’s | 100% |

32% cost reduction!

Insert unit price ÷ Number of corners used (life) x Number of teeth

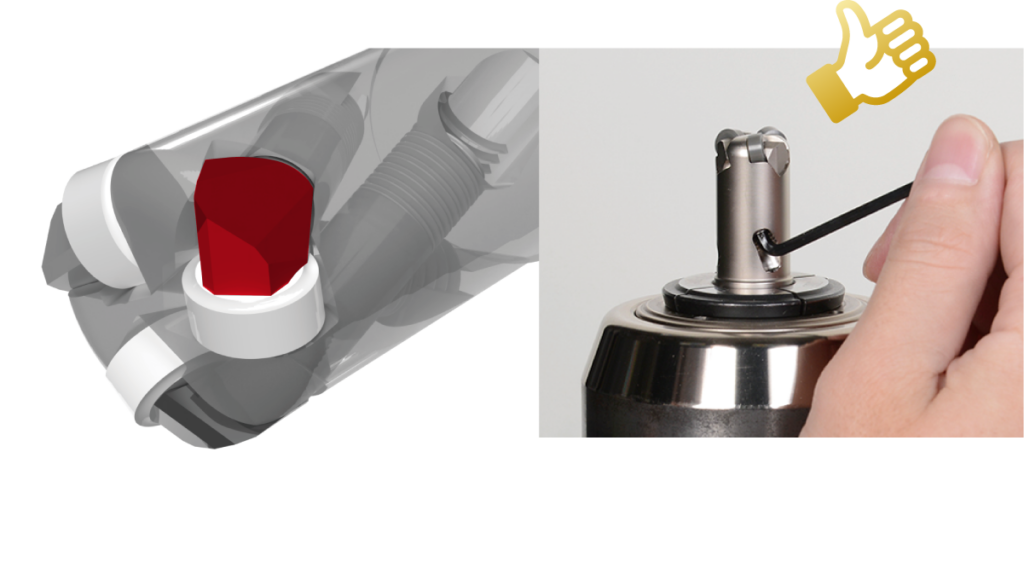

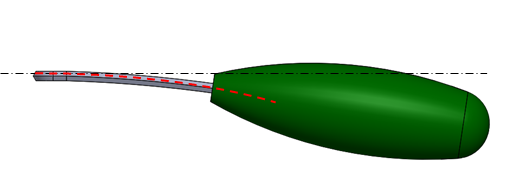

Approximately 2N・m

(recommend torque)

Approximately 6N・m

(more than recommend torque)

Tighten until it bends

For more information about this product, visit our online e-catalog, or download the catalog/product report