Heavy interrupted machining of hardened materials of HRC55 or above

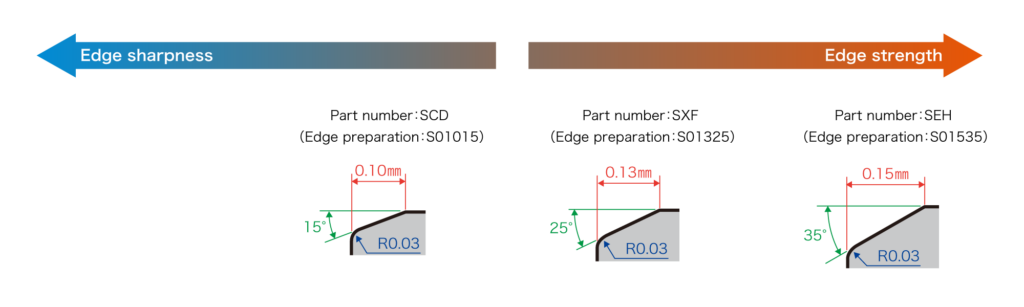

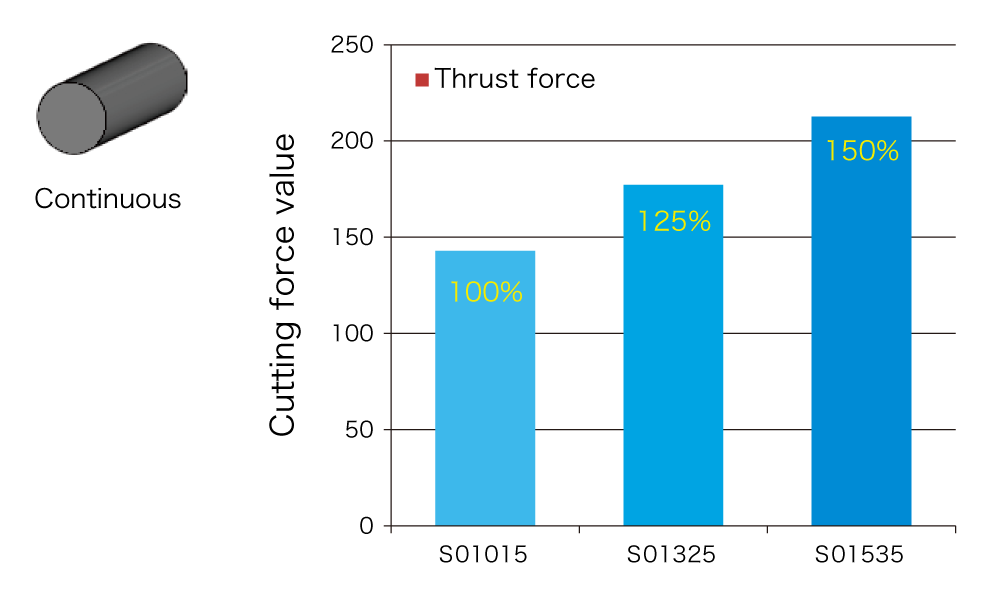

As the edge preparation increases the tool pressure on the insert increases.

[ Cutting conditions ]

SCM415(HRC63-65)

vc=200m/min f=0.1mm/rev ap=0.2mm

670 SFM .004 IPR .008 DOC

DRY

[ Insert ]

TNGA160408

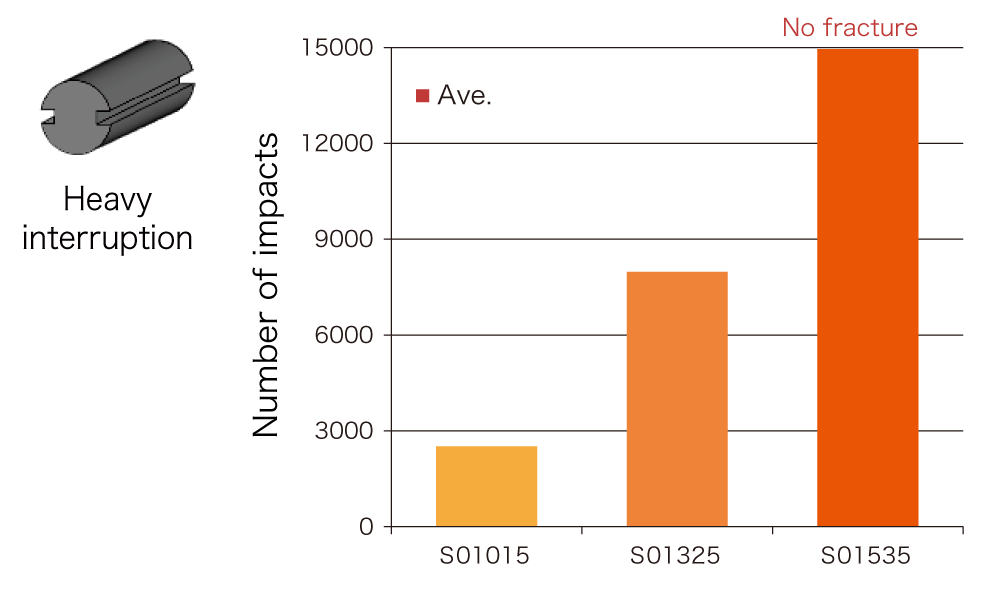

There is a direct correlation between an increase in the edge preparation and improvement of insert fracture resistance.

[ Cutting conditions ]

SCM415(HRC63-65)

vc=75m/min f=0.1mm/rev ap=0.3mm

250 SFM .004 IPR .012 DOC

DRY

[ Insert ]

TNGA160408

| ●1st Recommendation 〇2nd Recommendation |

||||||||

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR) | DOC(mm) DOC(inch) | DRY | WET |

|---|---|---|---|---|---|---|---|---|

| B40 | Hardened material (HRC 55 or above) | Turning Heavy interrupted machining | Finishing | 30 – 150 100 – 500 | ~ 0.1 ~ .004 | 0.1 – 1.0 .004 – .040 | ● | 〇 |

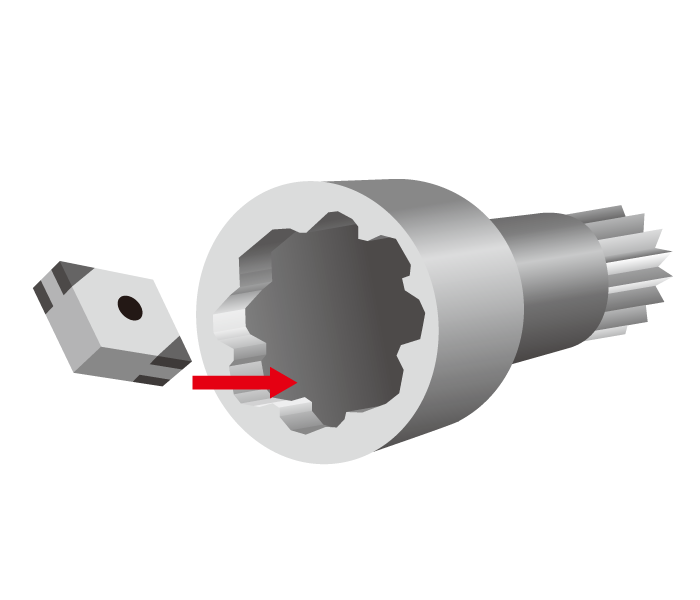

| Interrupted ID boring of automotive parts | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| B40 |

2,300 pcs / corner

|

|

| Competitor’s CBN |

1,500 pcs / corner

|

|

B40 achieved longer tool life through the heavy interruptions without chipping

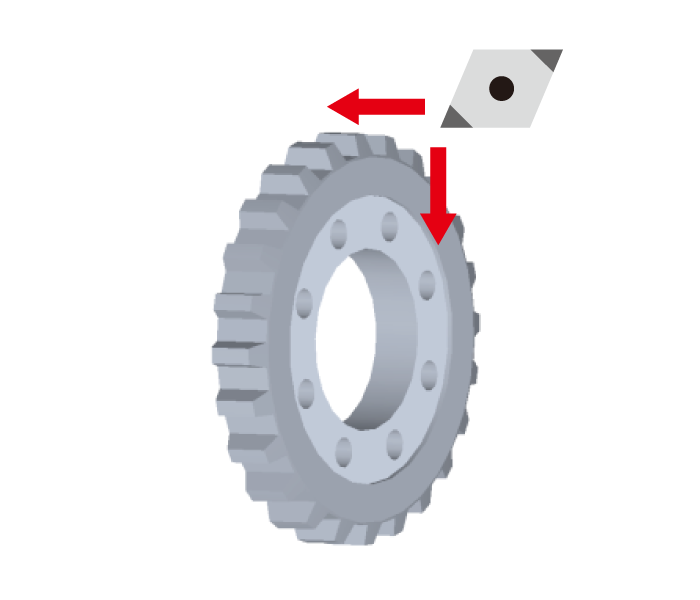

| Interrupted OD turning gear part coupling | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| B40 |

400 pcs / corner

|

|

| Competitor’s CBN |

100 pcs / corner

|

|

Competitor’s CBN had edge damage due to interruptions. B40’s excellent toughness achieved 4 times longer tool life.

For more information about this product, visit our online e-catalog, or download the catalog/product report