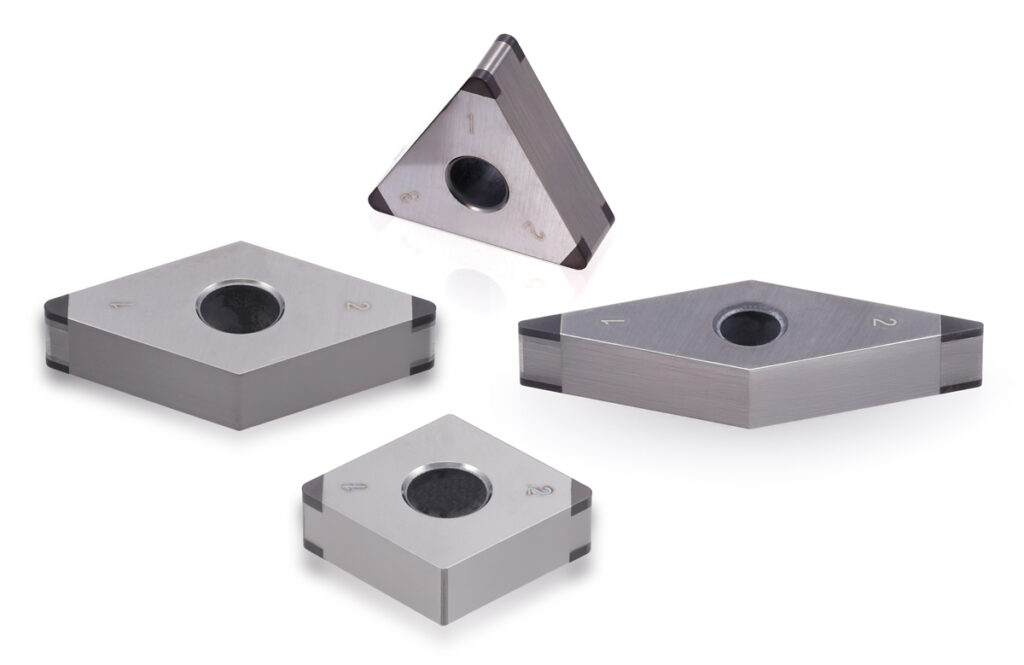

For turning Cast iron and Sintered powder alloy metals | Uncoated CBN

High CBN content provides stable wear resistance in high-speed turning of Gray cast iron and sintered alloys.

Fine particle size provides excellent edge sharpness and is effective in suppressing burrs.

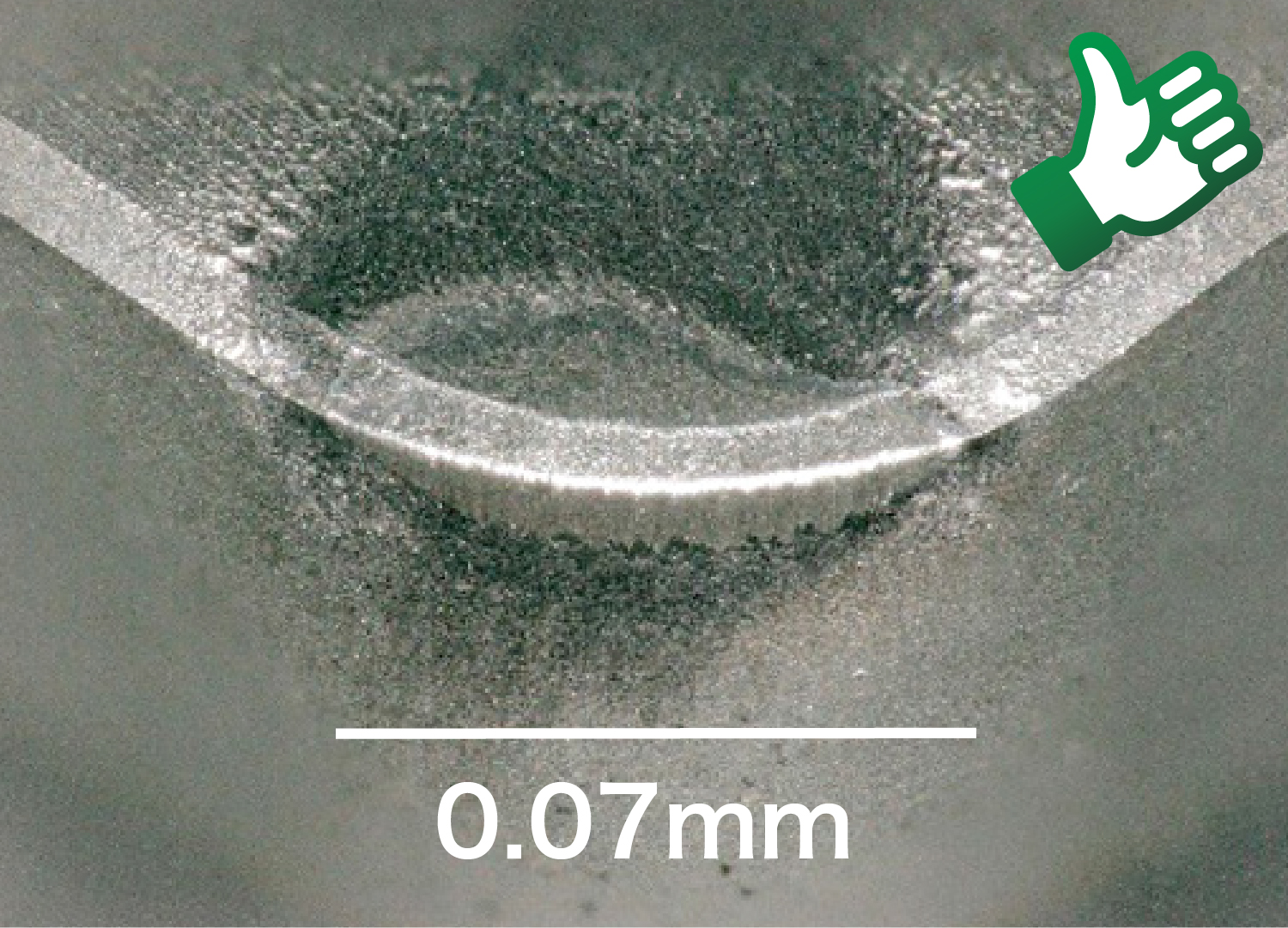

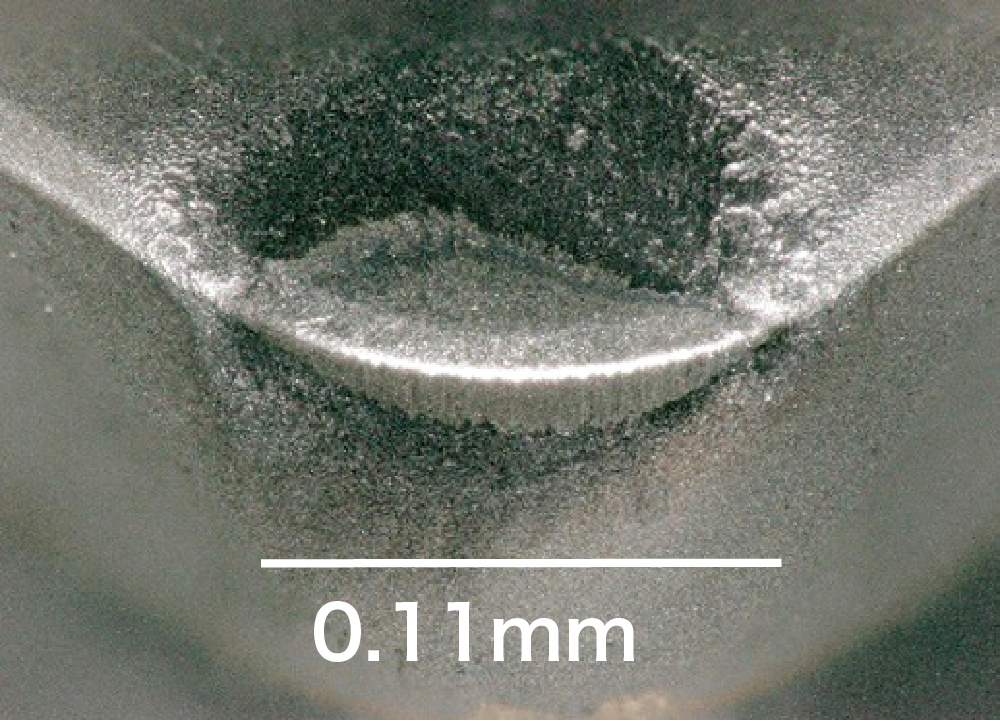

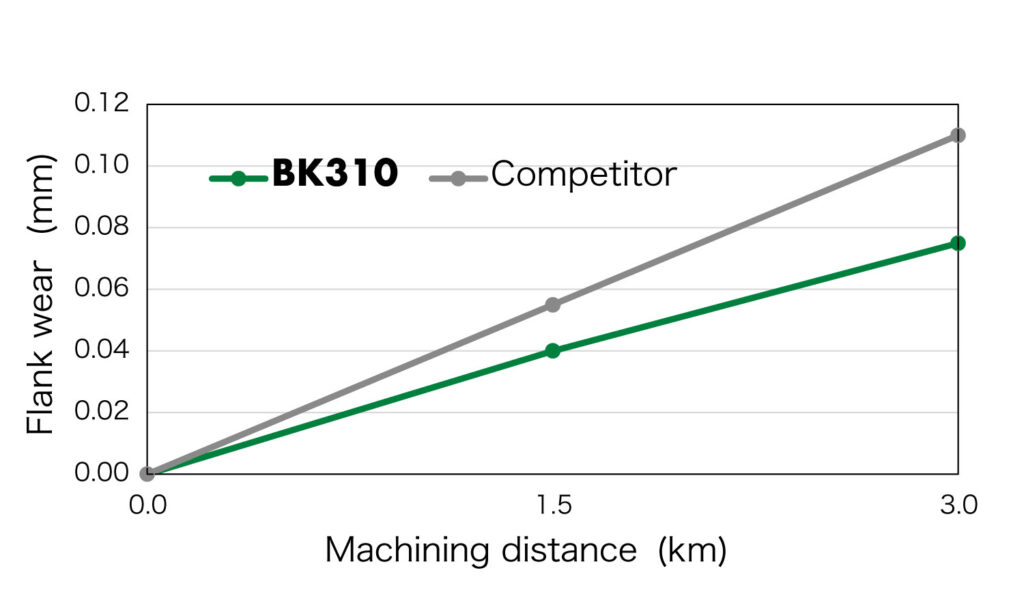

| BK310 | Competitor |

|---|---|

|

|

Gray cast iron (FC300)

vc =

500m/min

1600 SFM

, f =

0.3mm/rev

.012 IPR

, ap =

0.3mm

.012” DOC

,

After processing

3Km

120000”

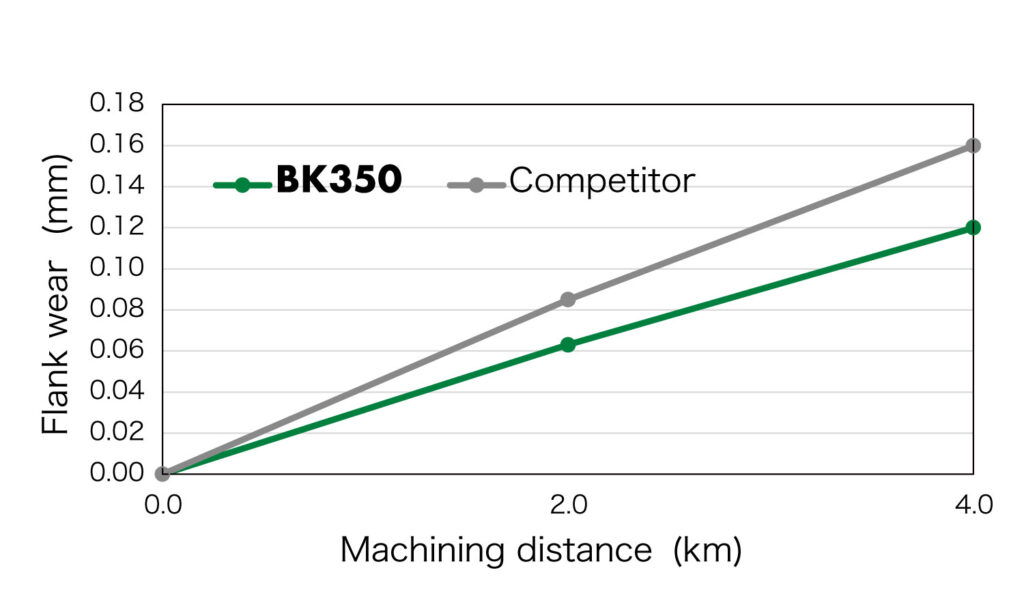

General-purpose material with excellent wear resistance and chipping resistance compared to

ductile cast iron for continuous to heavy interrupted use.

| BK350 | Competitor |

|---|---|

|

|

Ductile cast iron (FCD600)

vc =

300m/min

1000 SFM

, f =

0.1mm/rev

.004 IPR

, ap =

0.2mm

.008” DOC

,

After processing

4Km

160000”

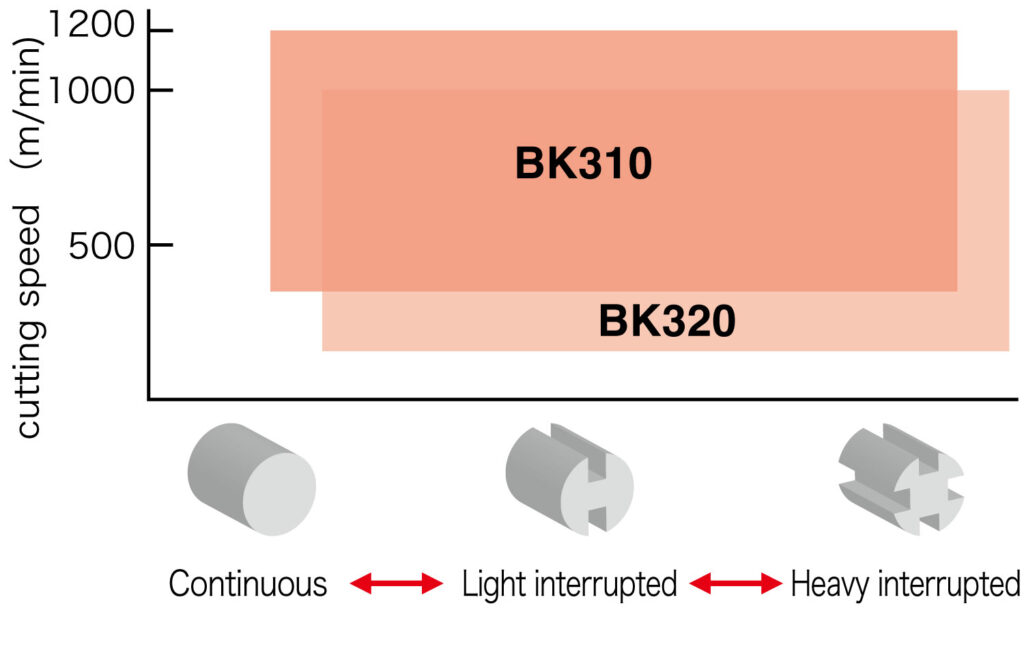

Cast iron – Finishing

BK310 and BK320 cutting conditions

| ●1st Recommendation 〇2nd Recommendation |

|||||

| Grade | Cutting speed | Feed | DOC | Coolant | |

|---|---|---|---|---|---|

| (m/min) (SFM) | (mm/rev) (IPR) | (mm) (inch) | DRY | WET | |

| BK310 BK320 | 400 – 1200 1300 – 3900 | up to 0.5 .020 | up to 2.0 .089 | 〇 | ● |

Sintered powder metal

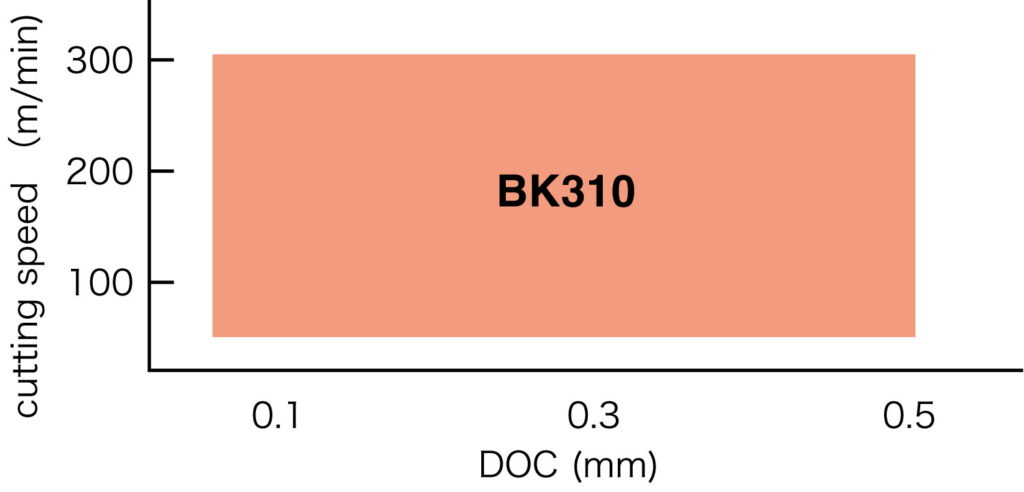

BK310 cutting conditions

| ●1st Recommendation 〇2nd Recommendation |

|||||

| Grade | Cutting speed | Feed | DOC | Coolant | |

|---|---|---|---|---|---|

| (m/min) (SFM) | (mm/rev) (IPR) | (mm) (inch) | DRY | WET | |

| BK310 | 40 – 300 130 – 980 | up to 0.5 .020 | up to 0.5 .020 | 〇 | ● |

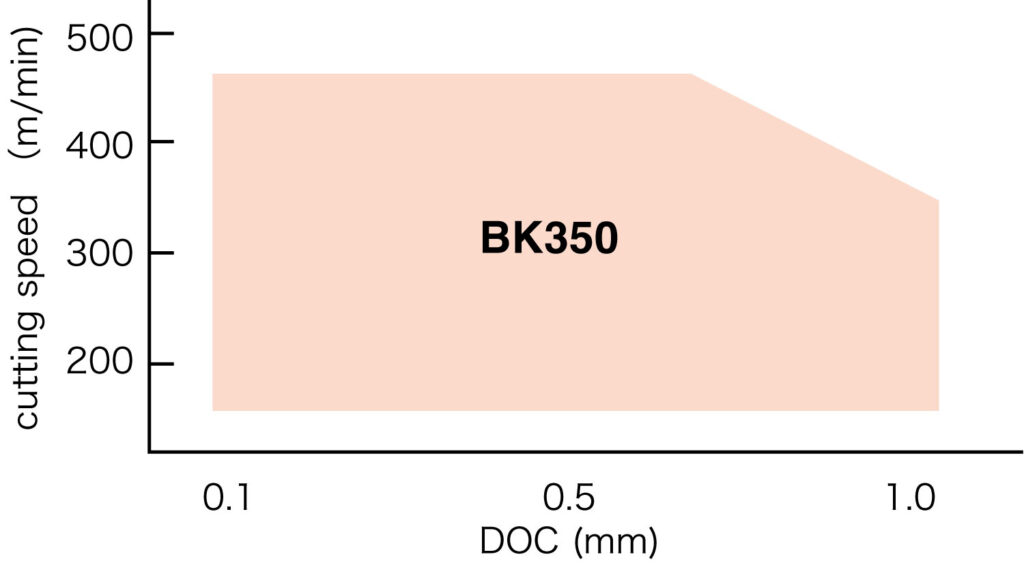

Ductile cast iron – Finishing

BK350 cutting conditions

| ●1st Recommendation 〇2nd Recommendation |

|||||

| Grade | Cutting speed | Feed | DOC | Coolant | |

|---|---|---|---|---|---|

| (m/min) (SFM) | (mm/rev) (IPR) | (mm) (inch) | DRY | WET | |

| BK350 | 100 – 450 330 – 1480 | up to 0.2 .008 | up to 1.0 .040 | ● | 〇 |

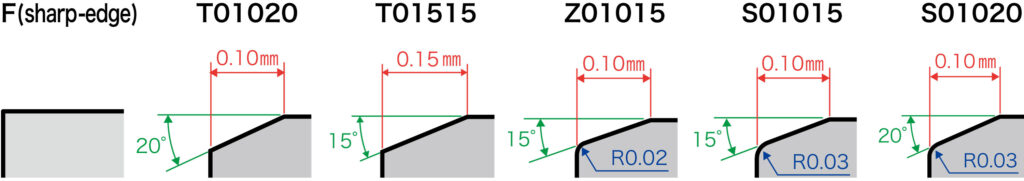

← Sharpness

Toughness →

| Agriculture Parts | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

|

||

| BK310 |

150 pcs / corner

|

|

| Competitor’s CBN |

100 pcs / corner

|

|

Conventional CBN would experience chattering at the corners and reach the end of their tool life, but BK310 maintains its sharpness and achieved 1.5 times longer tool life.

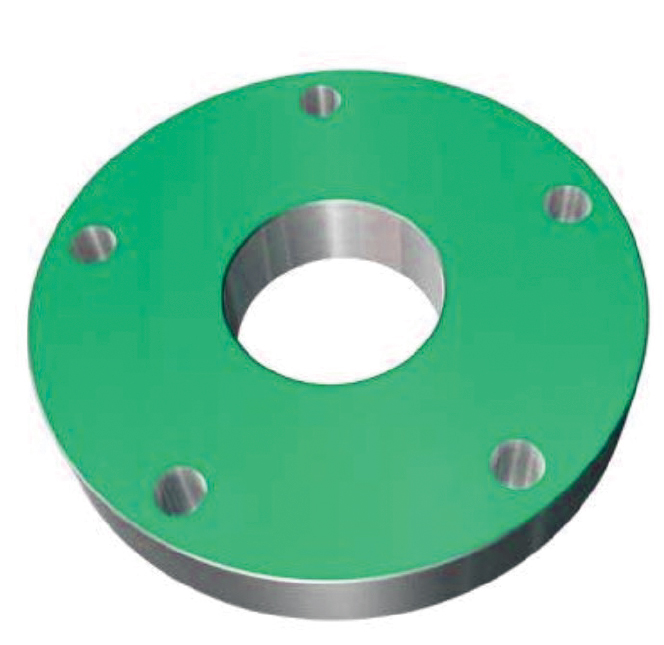

| Machinery parts | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

|

||

| BK350 |

100 pcs / corner

|

|

| Competitor’s CBN |

50 pcs / corner

|

|

Conventional CBN develop burrs in the hole and reach the end of its tool life, but BK350 maintains its sharpness and achieves twice the tool life.

For more information about this product, visit our online e-catalog, or download the catalog/product report