For machining ductile cast iron| TiC ceramic + alumina

For machining ductile cast iron| TiC ceramic + alumina

Specialized ceramic for finishing ductile iron

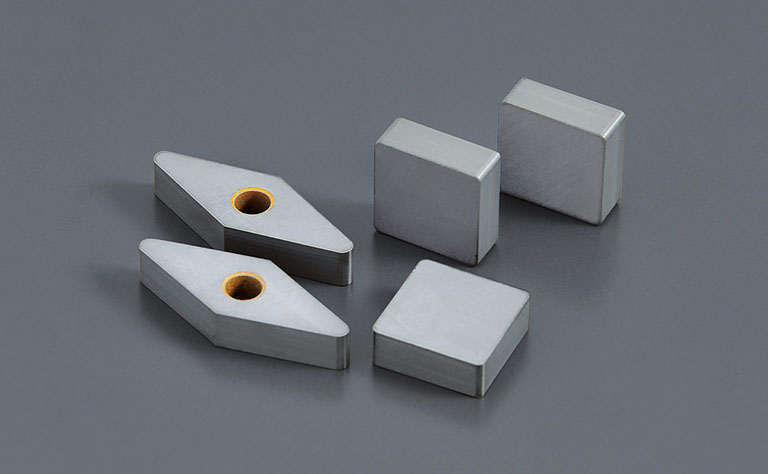

TiC based Alumina ceramic designed specifically for machining ductile cast iron

High-speed finishing at Vc=~400m/min

Features

- The world's first Alumina-TiC based ceramic grade

- Ceramic developed to target machining ductile cast iron

- Exceptional wear resistance extends tool life even at high cutting speeds

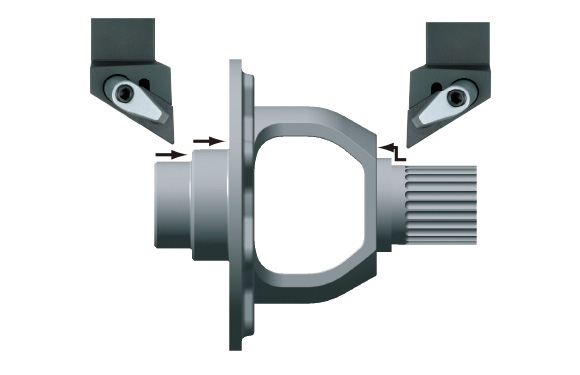

Tooling application

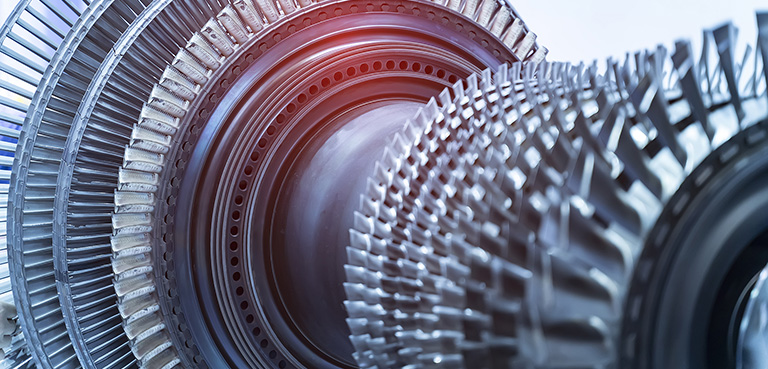

Ductile cast iron

Finish Turning

Grade characteristics

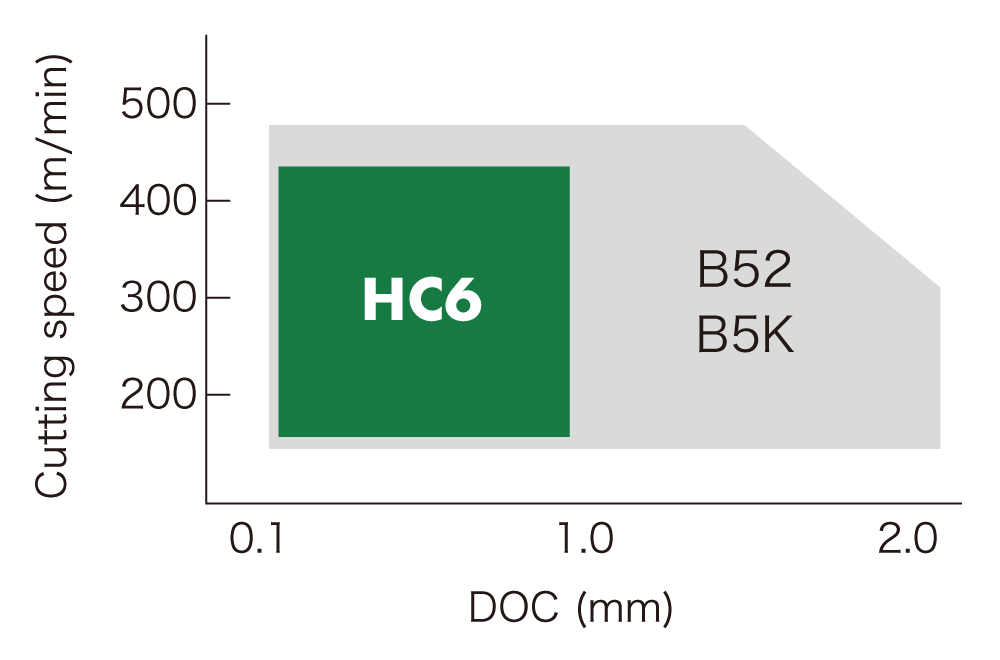

Cutting conditions

Scroll the table →

| Grade | Material | Operation type | Machining | Cutting speed (m/min) | Feed(mm/rev) | DOC(mm) | Coolant |

|---|---|---|---|---|---|---|---|

| HC6 | Ductile cast iron | Turning | Finishing | 200 - 500 | 0.1 - 0.3 | -1.0 | DRY / WET |

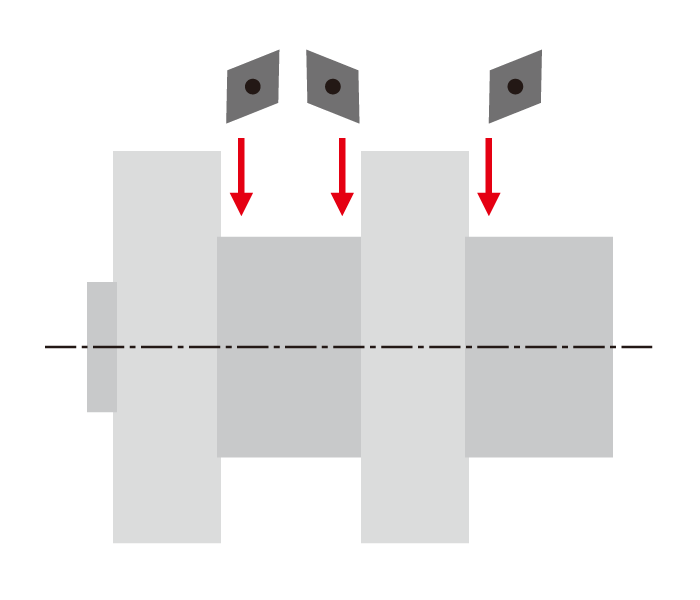

Case study

| Differential case | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| HC6 | 60 pcs / corner |

|

| Competitor’s CVD coated carbide | 30 pcs / corner |

|

- HC6 machined with 2 times the tool life of the competitor's CVD coated carbide.

| Camshaft | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| HC6 | 650 pcs / corner |

|

| Competitor’s CVD coated carbide | ||

- HC6 achieved 2 times longer tool life compared to the competitor's CVD coated carbide.

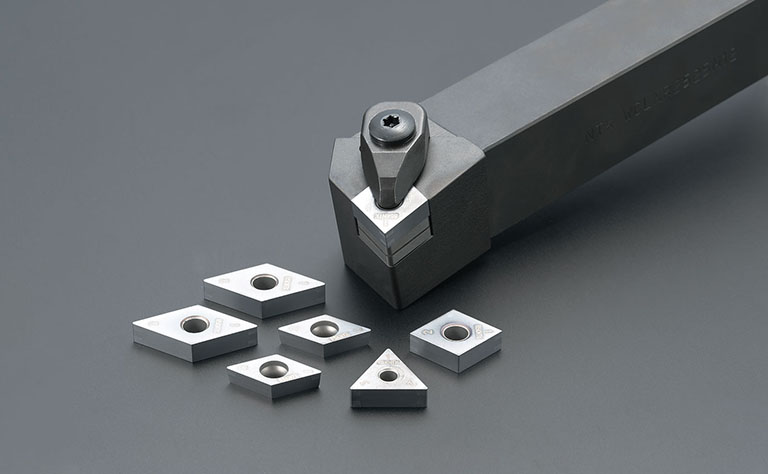

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

B5K/B52CBN grades for finishing ductile cast iron| Coated (B5K) / Un-coated (B52)

Best CBN grades for high-speed finishing of ductile cast iron

-

SP9Roughing to finishing of ductile cast iron & gray cast iron| Coated Silicon Nitride Ceramic

Covers roughing to finishing operations

-

SX6Exceptional wear resistance for rough machining of gray cast iron| Silicon nitride ceramic

First recommendation for roughing gray cast iron

-

SX9Excellent notch and flank wear resistance when roughing gray cast iron|Sialon ceramic

Ceramic grade with the best fracture resistance

Useful information

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert〔 Milling roughness to semi-finishing of heat-resistant alloys 〕 Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕

Points for maximizing the performance of ceramic insert 〔 Rough to semi-finish turning of heat-resistant alloys 〕 Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics

Tips for effectively cutting nickel-based alloys by knowing the material’s characteristics How to Make Ceramic Cutting Tools from Scratch

How to Make Ceramic Cutting Tools from Scratch