Non-ferrous material machining | Carbide grade for Swiss CNC lathes

Non-ferrous materials such as aluminum, brass, copper, and plastics

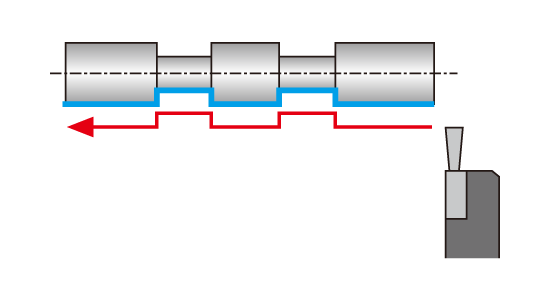

Front turning / Back turning / Grooving / Cut off / Threading

| Spool | |

|---|---|

|

|

|

|

|

|

|

|

|

|

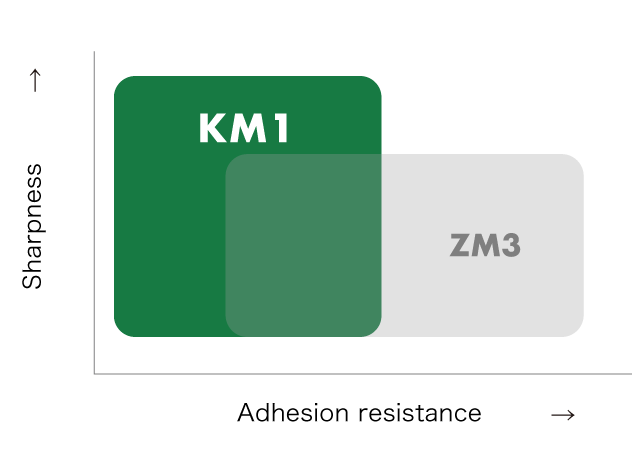

| KM1 |

300 pcs and more

|

| Competitor’s PVD coated carbide |

200 pcs

|

Competitor’s product performed 3 rough grooving passes and 1 finishing pass but inserts were chipped and worn.

The total cycle time took over 3 minutes. KM1 performed operation in 1 pass with a cycle time of 1 minute and 50 seconds.

For more information about this product, visit our online e-catalog, or download the catalog/product report

Other recommend products