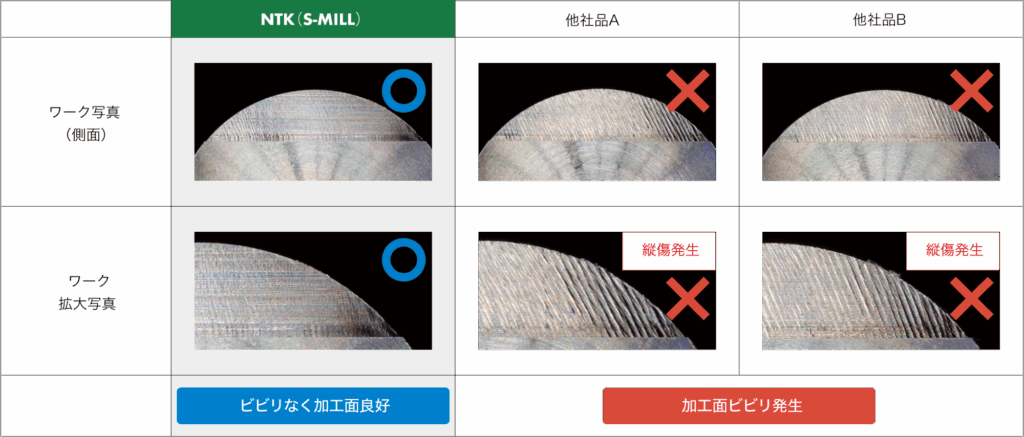

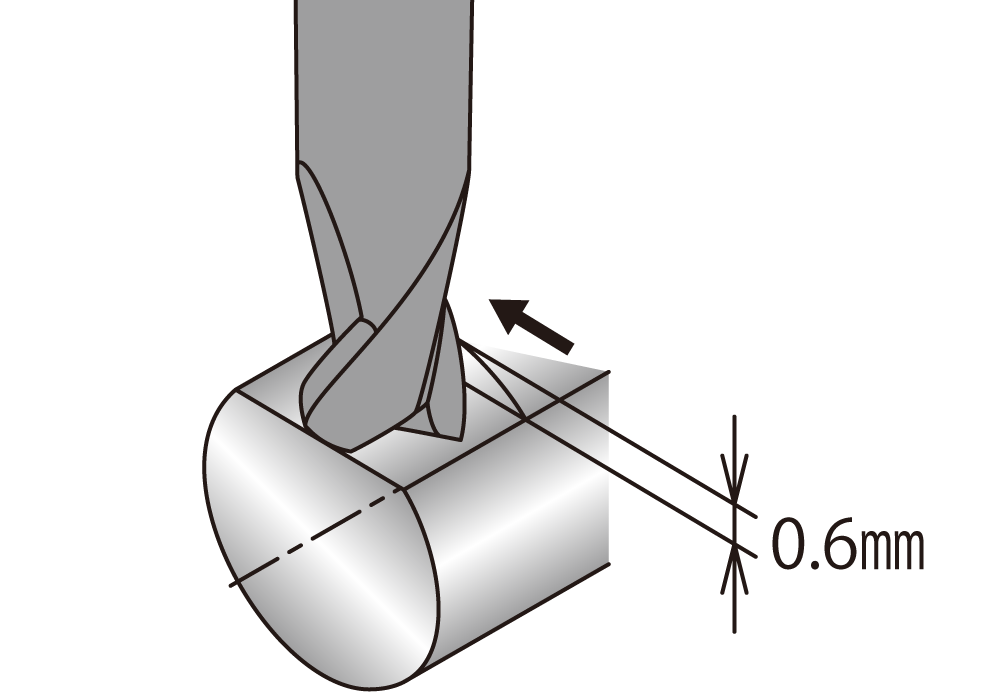

ワーク剛性が弱いエンドミル加工

( 小径ワーク、ガイドブッシュから離れた加工など )

[ 切削条件 ]

被削材 :

SUS304 Φ16.0 ap=3.0mm ae=1.2mm S = 3,000rpm F = 300mm/min

304SS Φ.630” .118 DOC ae=.047 S = 3,000rpm F = 11.8 IPM

[ 使用工具 ]

Φ6.0mm

Φ.236”

– 2枚刃

| 刃数 | 刃径 ⌀Dc (mm) |

一般鋼 S45C |

合金鋼 SCM435 |

ステンレス SUS304 |

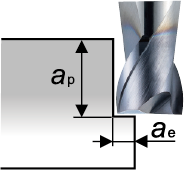

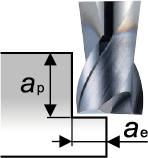

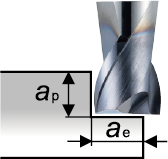

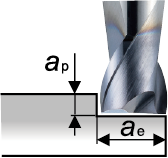

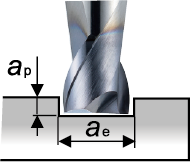

ae = ⌀Dc × 0.2

ae = ⌀Dc × 0.2 |

ae = ⌀Dc × 0.5

ae = ⌀Dc × 0.5 |

ae = ⌀Dc × 0.75

ae = ⌀Dc × 0.75 |

ae = ⌀Dc × 0.9

ae = ⌀Dc × 0.9 |

ae = ⌀Dc

ae = ⌀Dc |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| rpm | IPM | rpm | IPM | rpm | IPM | ap (inch) | ae (inch) | ap (inch) | ae (inch) | ap (inch) | ae (inch) | ap (inch) | ae (inch) | ap (inch) | ||

| 2 flute | 2.0 | 14,300 | 9.1 | 11,100 | 7.1 | 10,300 | 5.5 | ≦.079 | .016 | ≦.031 | .039 | ≦.024 | .059 | ≦.020 | .071 | ≦.016 |

| 3.0 | 9,500 | 13.0 | 7,400 | 10.2 | 6,900 | 8.3 | ≦.118 | .024 | ≦.047 | .059 | ≦.035 | .091 | ≦.028 | .106 | ≦.024 | |

| 4.0 | 7,200 | 15.4 | 5,600 | 11.8 | 5,200 | 9.4 | ≦.157 | .031 | ≦.063 | .079 | ≦.047 | .118 | ≦.039 | .142 | ≦.031 | |

| 5.0 | 5,700 | 16.5 | 4,500 | 13.0 | 4,100 | 10.2 | ≦.197 | .039 | ≦.079 | .098 | ≦.059 | .150 | ≦.047 | .177 | ≦.039 | |

| 6.0 | 4,800 | 17.3 | 3,700 | 13.4 | 3,400 | 10.6 | ≦.236 | .047 | ≦.094 | .118 | ≦.071 | .177 | ≦.059 | .213 | ≦.047 | |

| 7.0 | 4,100 | 16.5 | 3,200 | 13.0 | 3,000 | 10.6 | ≦.236 | .055 | ≦.110 | .138 | ≦.083 | .209 | ≦.067 | .248 | ≦.055 | |

| 8.0 | 3,600 | 16.1 | 2,800 | 12.6 | 2,600 | 9.8 | ≦.236 | .063 | ≦.126 | .157 | ≦.094 | .236 | ≦.079 | .283 | ≦.063 | |

| 10.0 | 2,900 | 14.6 | 2,200 | 11.0 | 2,100 | 9.1 | ≦.236 | .079 | ≦.157 | .197 | ≦.118 | .295 | ≦.098 | .354 | ≦.079 | |

| 3 flute | 3.0 | 9,500 | 15.4 | 7,400 | 12.2 | 6,900 | 9.8 | ≦.118 | .315 | ≦.047 | .059 | ≦.035 | .091 | ≦.028 | .106 | ≦.024 |

| 4.0 | 7,200 | 18.5 | 5,600 | 14.2 | 5,200 | 11.4 | ≦.157 | .031 | ≦.063 | .079 | ≦.047 | .118 | ≦.039 | .142 | ≦.031 | |

| 5.0 | 5,700 | 19.7 | 4,500 | 15.7 | 4,100 | 12.2 | ≦.197 | .039 | ≦.079 | .098 | ≦.059 | .150 | ≦.047 | .177 | ≦.039 | |

| 6.0 | 4,800 | 20.9 | 3,700 | 16.1 | 3,400 | 13.0 | ≦.236 | .047 | ≦.094 | .118 | ≦.071 | .177 | ≦.059 | .213 | ≦.047 | |

| 7.0 | 4,100 | 20.1 | 3,200 | 15.7 | 3,000 | 12.6 | ≦.236 | .055 | ≦.110 | .138 | ≦.083 | .209 | ≦.067 | .248 | ≦.055 | |

| 8.0 | 3,600 | 19.3 | 2,800 | 15.0 | 2,600 | 12.2 | ≦.236 | .063 | ≦.126 | .157 | ≦.094 | .236 | ≦.079 | .283 | ≦.063 | |

| 10.0 | 2,900 | 17.3 | 2,200 | 13.0 | 2,100 | 11.0 | ≦.236 | .079 | ≦.157 | .197 | ≦.118 | .295 | ≦.098 | .354 | ≦.079 | |

| 4 flute | 3.0 | 9,500 | 18.1 | 7,400 | 14.2 | 6,900 | 11.4 | ≦.118 | .024 | ≦.047 | .059 | ≦.035 | .091 | ≦.028 | .106 | ≦.024 |

| 4.0 | 7,200 | 21.3 | 5,600 | 16.5 | 5,200 | 13.4 | ≦.157 | .031 | ≦.063 | .079 | ≦.047 | .118 | ≦.039 | .142 | ≦.031 | |

| 5.0 | 5,700 | 23.2 | 4,500 | 18.1 | 4,100 | 14.6 | ≦.197 | .039 | ≦.079 | .098 | ≦.059 | .150 | ≦.047 | .177 | ≦.039 | |

| 6.0 | 4,800 | 24.4 | 3,700 | 18.9 | 3,400 | 15.0 | ≦.236 | .047 | ≦.094 | .118 | ≦.071 | .177 | ≦.059 | .213 | ≦.047 | |

| 7.0 | 4,100 | 23.2 | 3,200 | 18.1 | 3,000 | 15.0 | ≦.236 | .055 | ≦.110 | .138 | ≦.083 | .209 | ≦.067 | .248 | ≦.055 | |

| 8.0 | 3,600 | 22.4 | 2,800 | 17.3 | 2,600 | 14.2 | ≦.236 | .063 | ≦.126 | .157 | ≦.094 | .236 | ≦.079 | .283 | ≦.063 | |

| 10.0 | 2,900 | 20.1 | 2,200 | 15.4 | 2,100 | 12.6 | ≦.236 | .079 | ≦.157 | .197 | ≦.118 | .295 | ≦.098 | .354 | ≦.079 | |

| ⌀6mm ⌀.236” – 2枚刃Dカット | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| S-MILL |

12,000個/コーナ+α

|

| 他社ソリッドエンドミル |

10,000個/コーナ

|

現行品は寿命数まで加工すると加工面が曇ってくるが、S-MILLは曇り問題なく寿命延長を実現。

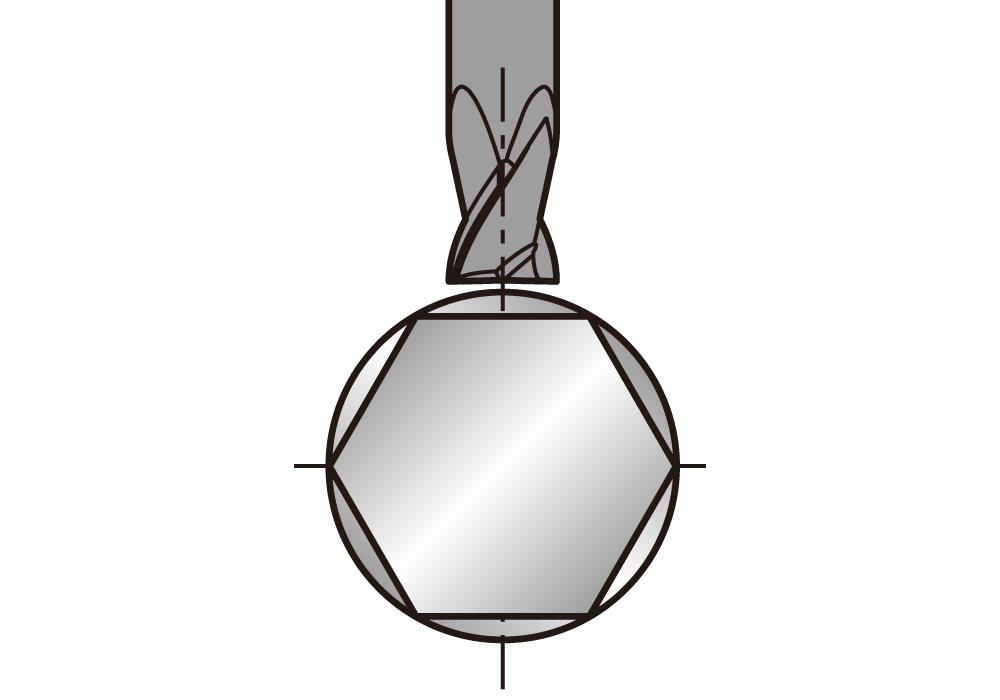

| ⌀6mm – 2枚刃 ⌀10mm → 対辺8mm ⌀.236” – 2枚刃 ⌀.394” → 対辺.315” の六角材加工 | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| S-MILL |

70個/コーナ+α

|

| 他社ソリッドエンドミル |

50個/コーナ

|

切れ味に優れるS-MILLは、現行品よりも加工音が小さくバリの発生を抑制し、寿命延長を実現。