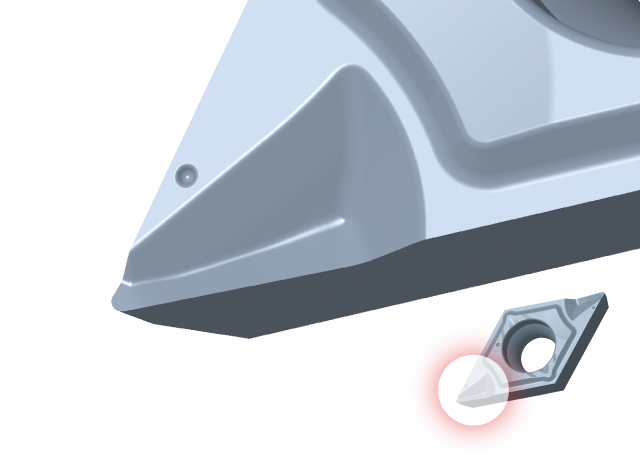

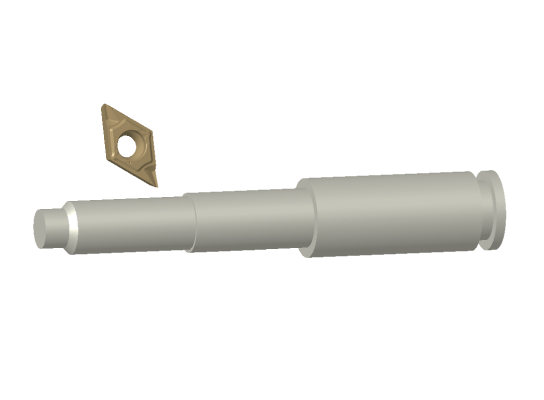

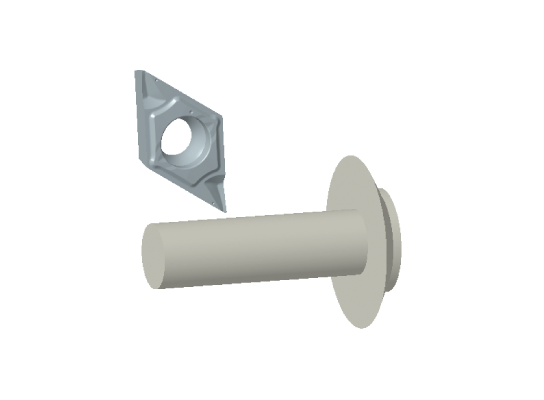

For Front Turning | Vibration / Oscillation & Conventional cutting Dual-Purpose Chipbreaker

Front turning operations on swiss cnc using vibration cutting function

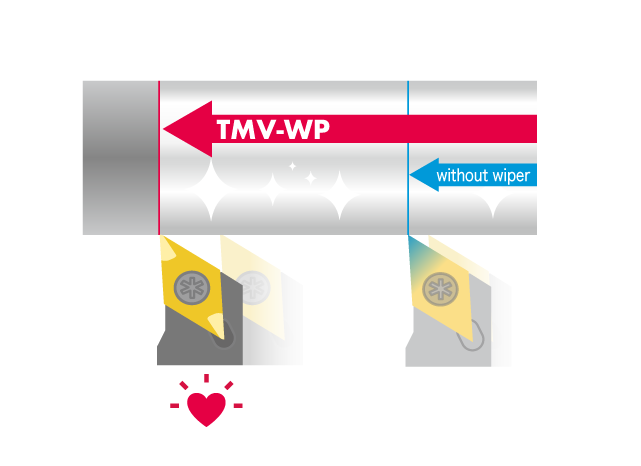

Double the feed rate and toollife & Reduce machining time by half.

Superior surface finish even under high feed conditions thanks to the wiper. Contributes to extended tool life by increasing feed.

| Grade | Work materials | Cutting conditions | ||

|---|---|---|---|---|

| Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/rev) Feed (IPR) | D.O.C. (mm) D.O.C. (inch) | ||

| NTK650 | Ni base alloy / Steel / Stainless steel ( Inco718 / S45C / SUS440C etc ) |

40 – 100 130 – 330 | 0.02 – 0.06 .0008 – .0024 | 0.5 – 2.0 .02 – .08 |

| ST4 | Austenitic stainless steel ( SUS304 / SUS316 etc 304SS / 316SS etc ) |

40 – 100 130 – 330 | 0.02 – 0.06 .0008 – .0024 | |

| DM4 | Carbon steel / Alloy steel ( S45C / SCM435 etc ) | 50 – 120 170 – 400 | 0.02 – 0.06 .0008 – .0024 | |

| TM4 | Non-ferrous ( Aluminum / Titanium etc ) | 60 – 150 200 – 500 | 0.02 – 0.06 .0008 – .0024 | |

| CITIZEN MACHINERY CO., LTD. Vibration condition ( LFV ) | ||

|---|---|---|

| P | Q | D |

| Mode 1 | 0.5 | 0.5 |

⚠ This product is designed with a low cutting edge, so please use it after aligning the core.

⚠ * When using an

R0.08

radius R.003

insert, set the feed

0.02mm/rev

.0008”/rev

or less. [ Mode 2 / E4.0 / R0.5 ] is recommended when feed rate is higher than

0.02mm/rev

.0008”/rev

.

| Star precision Co., Ltd. Vibration Conditions (Step Cycle Pro) | |

|---|---|

| A (Chip length factor) | D (Amplitude factor) |

| More than 2.0 | More than 2.0 |

⚠ Our products are designed with a low cutting edge, please use them after aligning with the center.

⚠ * When using insert radius

R0.08

radius R.003

, please set the feed rate to

0.02mm/rev

.0008”/rev

or less.

| Tsugami Corporation. Oscillation conditions | |

|---|---|

| I (Oscillation frequency ratio) | K (Oscillation amplitude ratio) |

| 0.5 | 1.5 |

⚠ Our products are designed with a low cutting edge, please use them after aligning with the center.

⚠ * When using insert radius

R0.08

radius R.003

, please set the feed rate to

0.02mm/rev

.0008”/rev

or less. If the chips are not broken in pieces, consider adjusting K in the range from 1.2 – 2.0 as a guideline

| CNC Lathe | Cincom L20-LFV |

| Work material | SUS316L 316LSS |

| Cutting speed | 80 m/min 270 SFM |

| Feed | 0.05 mm/rev .002 IPR |

| D.O.C. (ap) | 1.0 mm .040” |

| Coolant | WET |

| Vibration condition | Mode 1 Q0.5 D0.5 |

* Materials other than stainless steel are currently being validated.

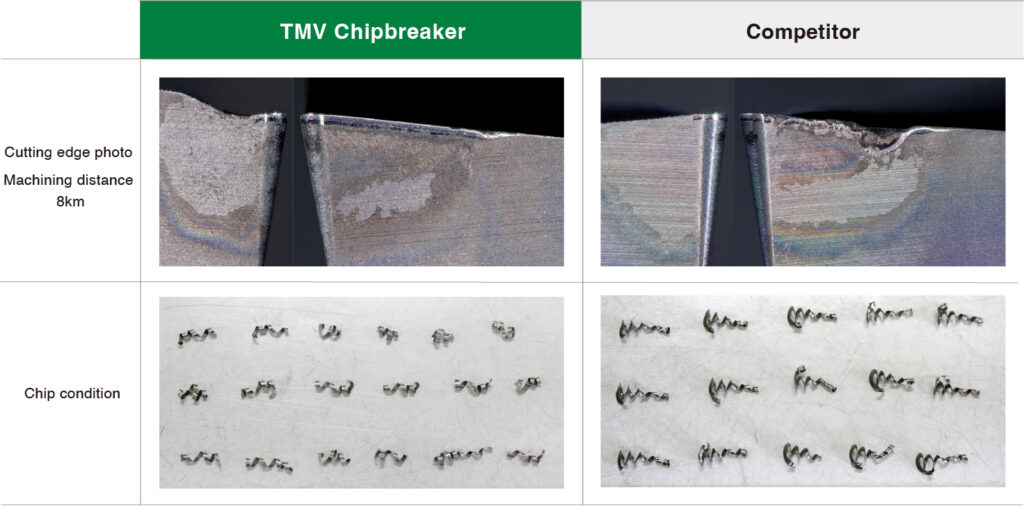

| Construction machine parts | |

|---|---|

|

Machining dia. :

φ8 / 10.8 / 12

φ.31” / .425” / .472” Machining dia. :

φ8 / 10.8 / 12

φ.31” / .425” / .472”

|

|

|

|

|

|

|

|

|

| DM4 DCGT11T302MRTMV |

600pcs / corner

|

| Competitor’s PVD carbide |

300pcs / corner

|

| Valve parts | |

|---|---|

|

Machining dia. :

φ3.8

φ.15” Machining dia. :

φ3.8

φ.15”

|

|

|

|

|

|

|

|

|

| ST4 DCGT11T302MRTMV |

3,000pcs / corner

|

| Competitor’s PVD carbide |

2,200pcs / corner

|

For more information about this product, visit our online e-catalog, or download the catalog/product report

Other recommend products