Roughing gray cast & ductile cast iron / CVD coated carbide

Gray cast iron/Ductile cast iron

Roughing with scale

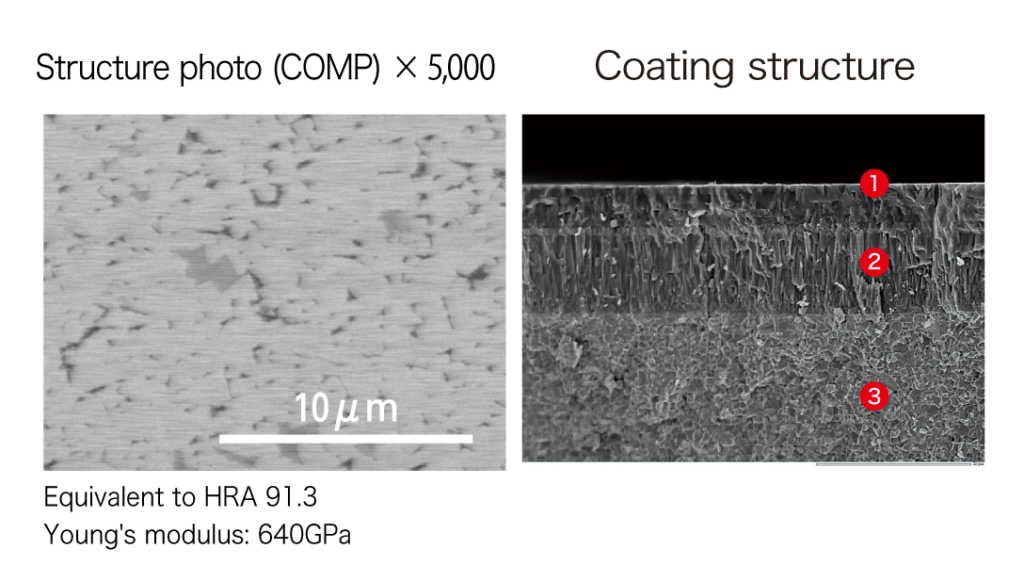

① A very smooth layer of fine grain Al2O3

② Fine column shaped grain TiCN layer

③ Ultra – hard cemented carbide base material

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR) | DOC(mm) DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|

| CP1 | Gray cast iron/Ductile cast iron | Turning | Roughing with scale, Rough to semi-finish machining | 100 – 300 300 – 1000 | 0.2 – 0.4 .008 – .016 | -5.0 – .197 | WET |

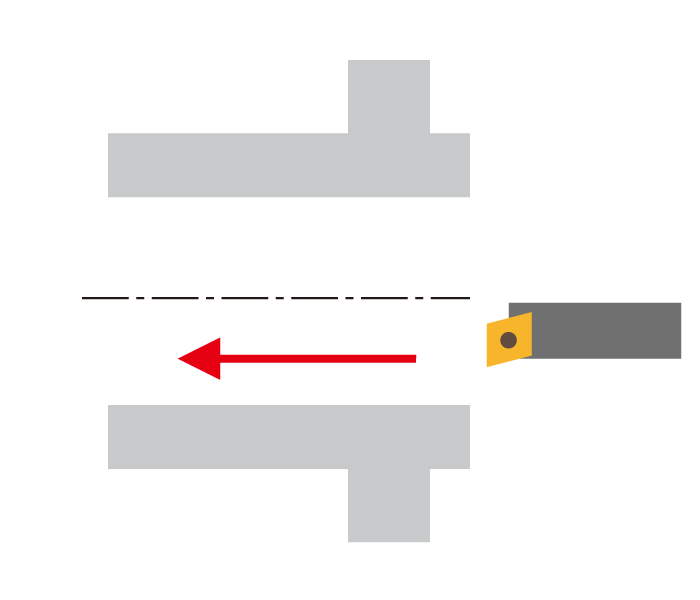

| ID boring of housing part | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| CP1 |

110 pcs / corner

|

|

| Competitor’s CVD coated carbide |

50 pcs / corner

|

|

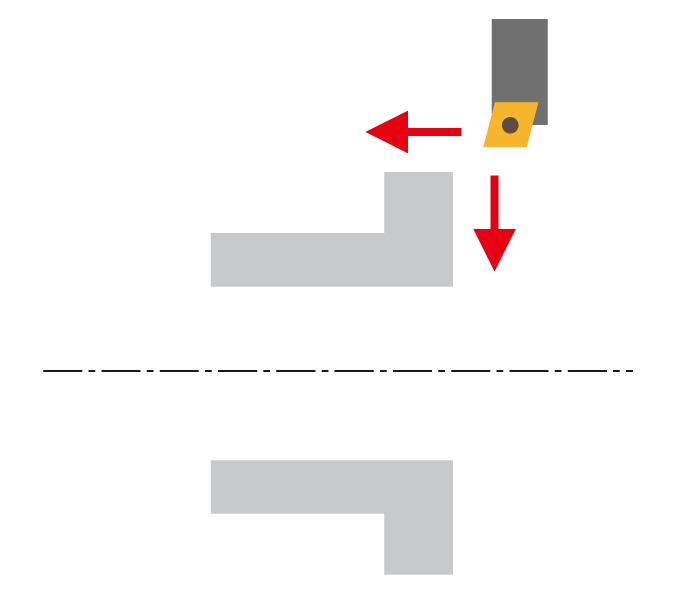

| OD machining of water pipe part | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| CP1 |

60 pcs / corner

|

|

| Competitor’s CVD coated carbide |

8 pcs / corner |

|

For more information about this product, visit our online e-catalog, or download the catalog/product report