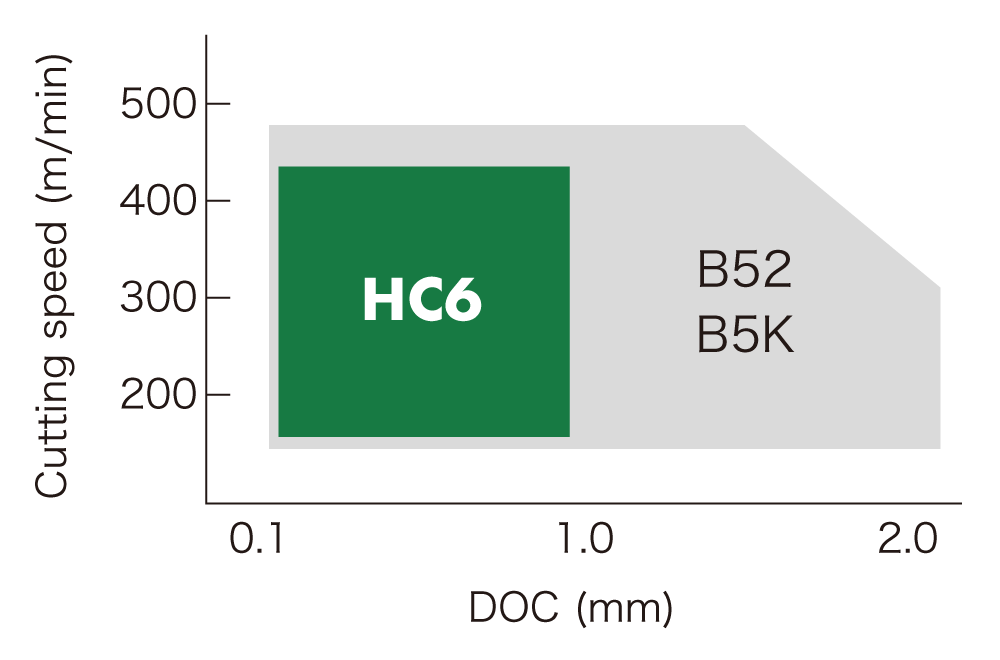

For machining ductile cast iron| TiC ceramic + alumina

Ductile cast iron

Finish Turning

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed(IPR) | DOC(mm) DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|

| HC6 | Ductile cast iron | Turning | Finishing | 200 – 500 600 – 1600 | 0.1 – 0.3 .004 – .012 | -1.0 – .040 | DRY / WET |

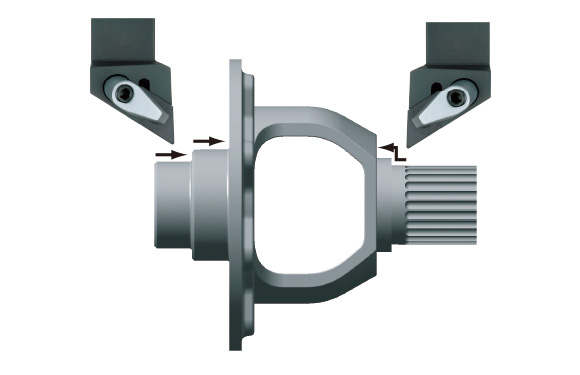

| Differential case | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| HC6 |

60 pcs / corner

|

|

| Competitor’s CVD coated carbide |

30 pcs / corner

|

|

HC6 machined with 2 times the tool life of the competitor’s CVD coated carbide.

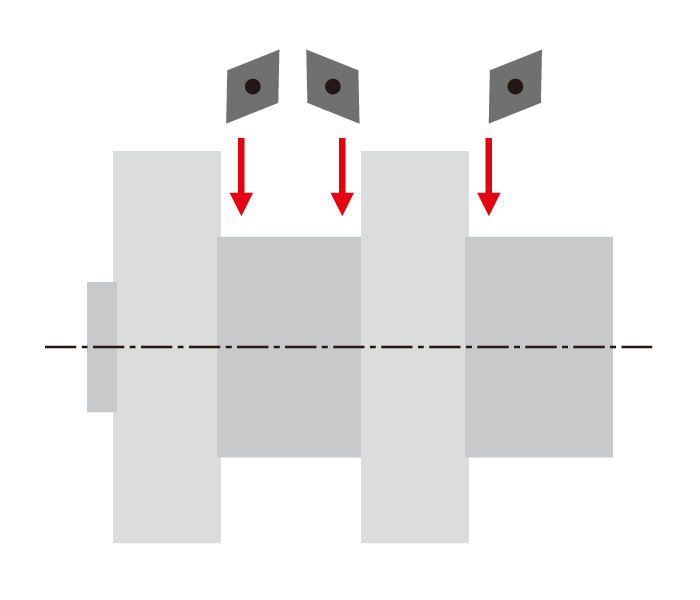

| Camshaft | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| HC6 |

650 pcs / corner

|

|

| Competitor’s CVD coated carbide |

150 pcs / corner |

|

HC6 achieved 2 times longer tool life compared to the competitor’s CVD coated carbide.

For more information about this product, visit our online e-catalog, or download the catalog/product report