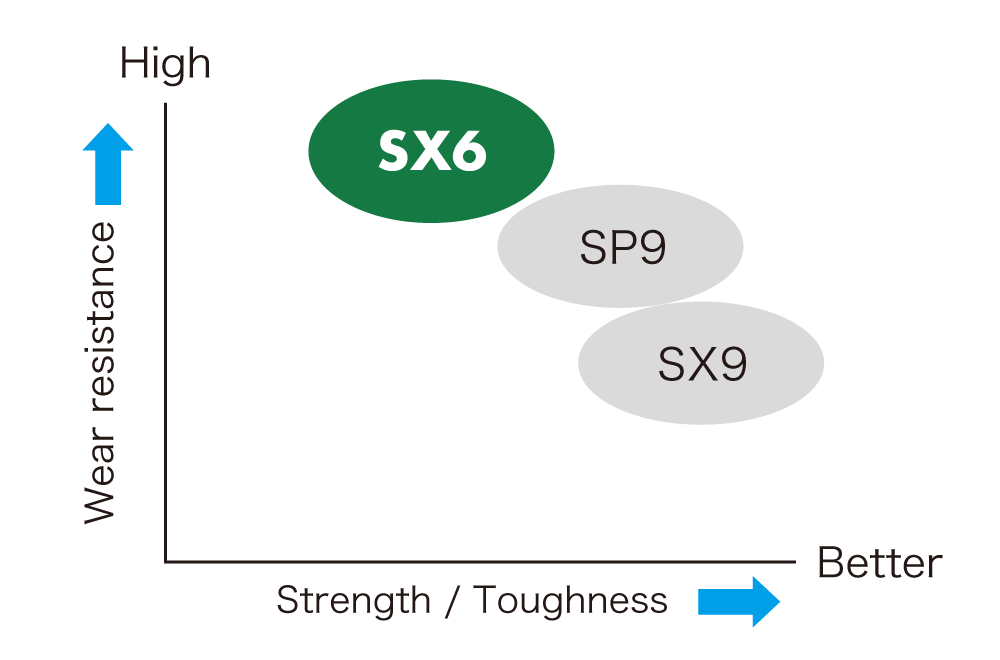

Exceptional wear resistance for rough machining of gray cast iron| Silicon nitride ceramic

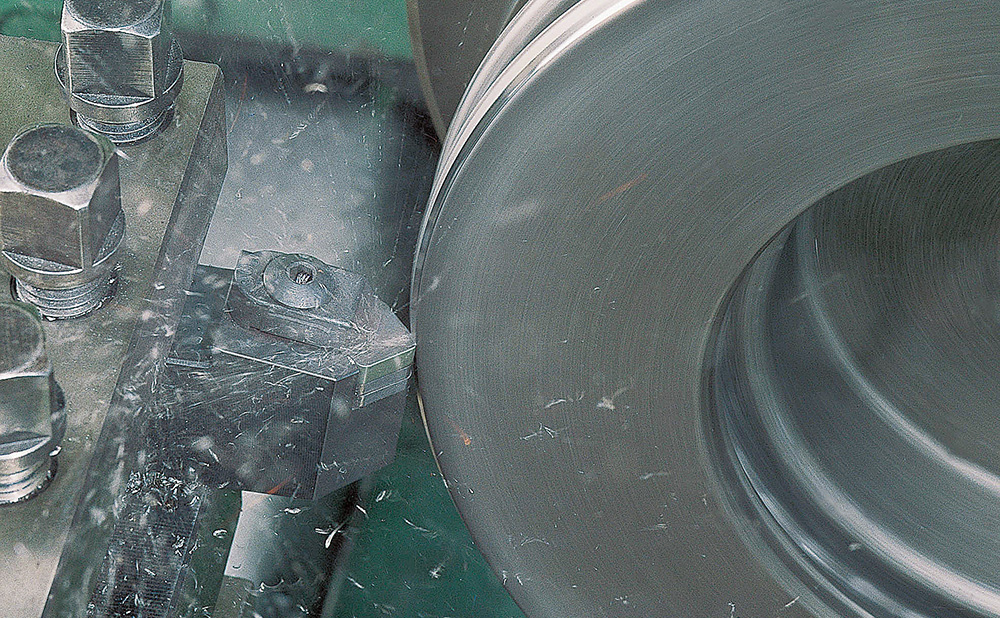

Gray cast iron with scale

Rough Turning/ Milling

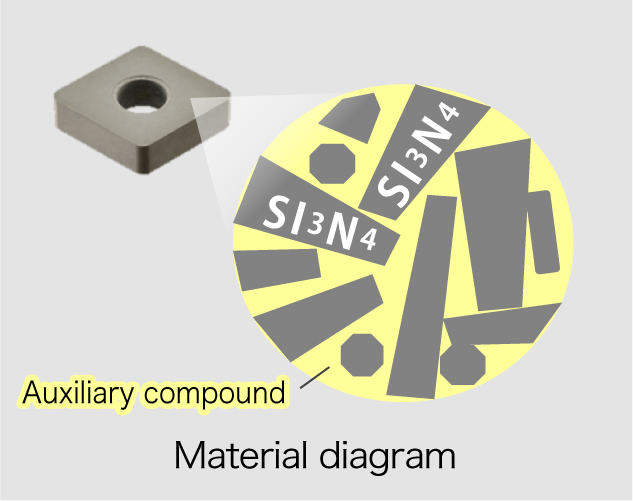

The main component is silicon nitride(Si3N4), which differs from alumina-based materials in that its particles are needle-like.

The intertwining of the needle-like particles greatly suppresses the progression of cracks caused by impact during cutting and prevents chipping.

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed (IPR /IPT) | DOC(mm) DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|

| SX6 | Gray cast iron | Turning | Roughing with scale, Rough to semi-finish machining | 450 – 1000 1500 -3500 | 0.3 – 0.5 .012 – .020 | -3.5 – .140 | DRY / WET |

| Milling | 450 – 1200 1500 -4000 | 0.07 – 0.2 .003 – .010 |

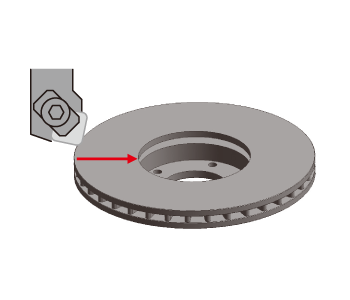

| Brake disc | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| SX6 |

75 pcs / corner

|

|

| Competitor’s silicon nitride |

50 pcs / corner

|

|

SX6 achieved 1.5 times longer tool life compared to competitor’s silicon nitride

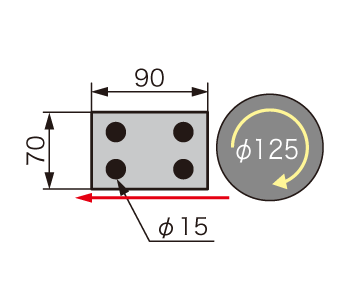

| Milling Application | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

|

||

| SX6 |

360 pcs / corner

|

|

| Competitor’s carbide inserts |

260 pcs / corner

|

|

High-speed milling with ceramic significantly reduced cycle time compared to the current carbide inserts. (Single pass process went from 40 min. down to 15min.)

SX6 achieved 1.4 times more tool life.

Tooling costs are reduced by utilizing negative inserts, increasing the number of corners.

For more information about this product, visit our online e-catalog, or download the catalog/product report