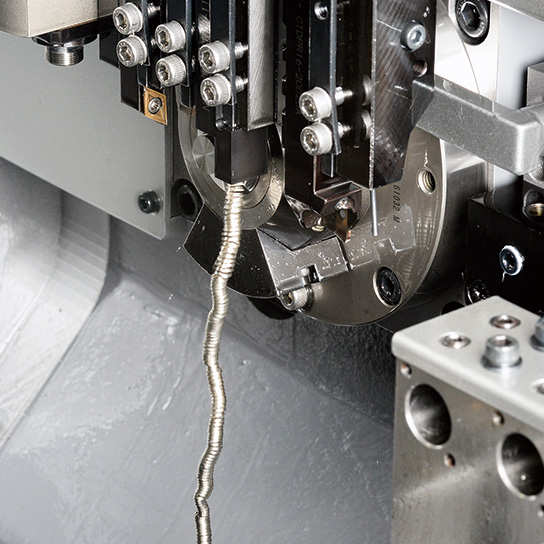

Selection for Front turning, back turning, grooving, Multi-functional groover (application-spool parts) | For Swiss CNC lathes (vertical gang style)

Front turning / Back turning / For grooving

Pure Copper Processing / Machining Plastics

Program sample

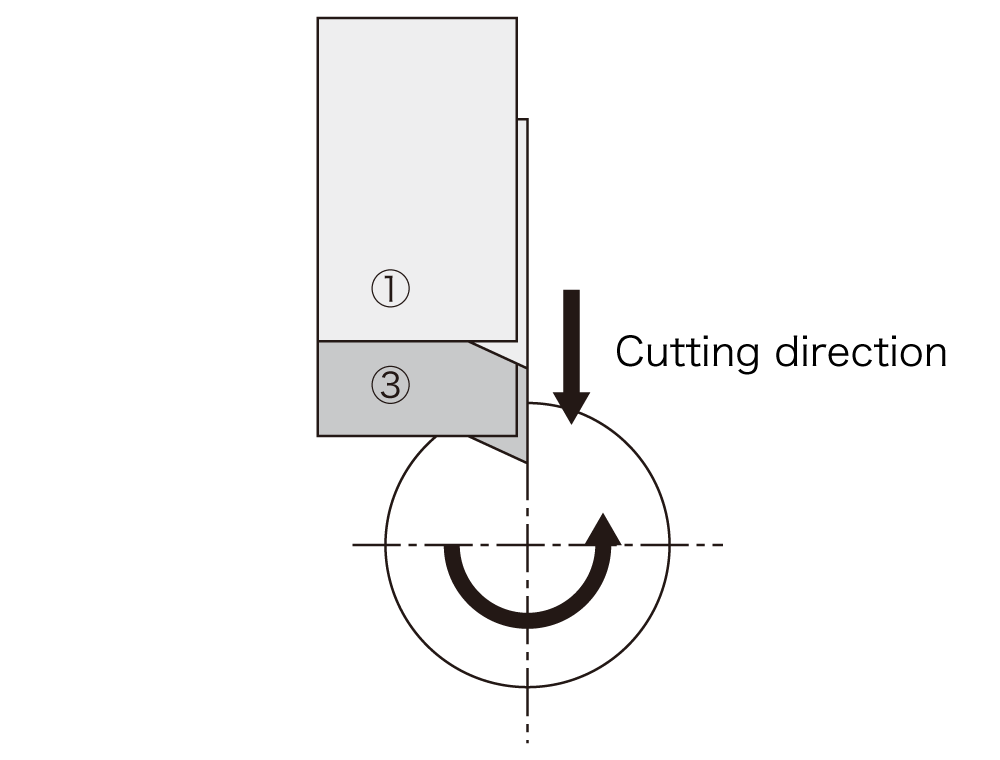

In general front turning machining a tool is selected and moved to readying position and then cutting is initiated.

The cut direction is the “X-axis“

Program sample

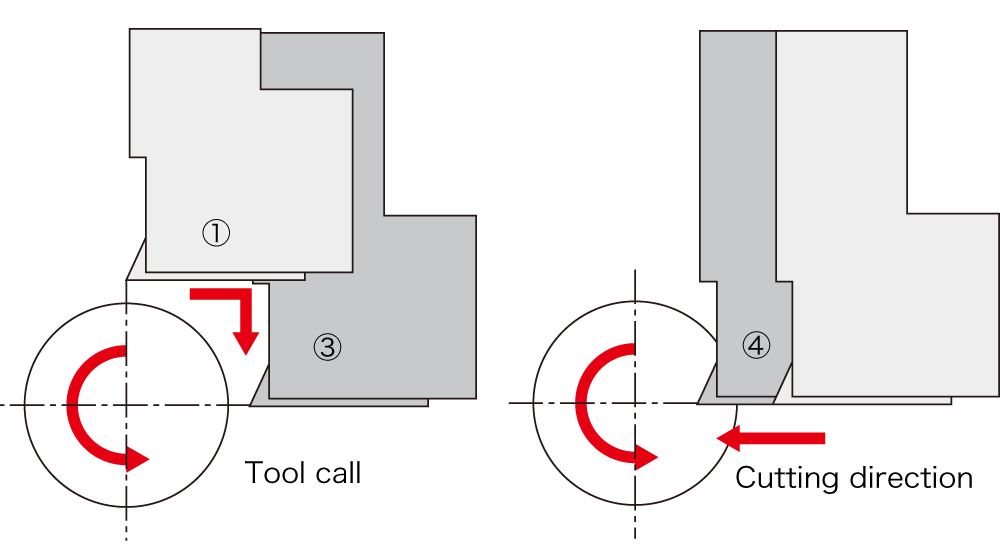

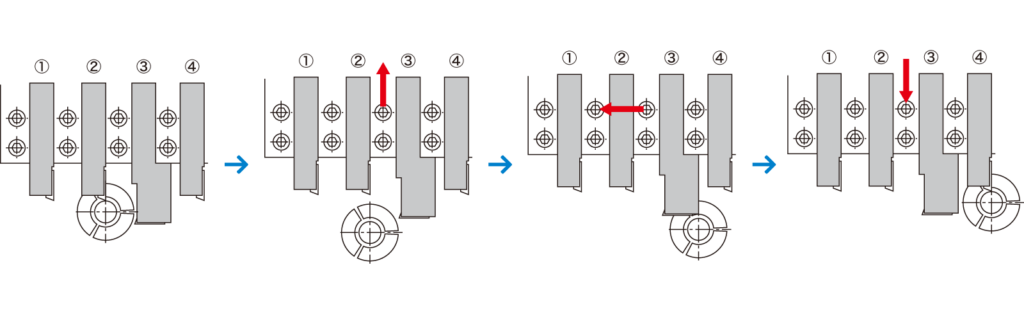

When using the Y-axis holder, the tool selection ①. Insert moved to cut position and cutting starts from this position.

The cut direction is the “Y axis“

Note: Need y-offset in the program for the holder shank size.

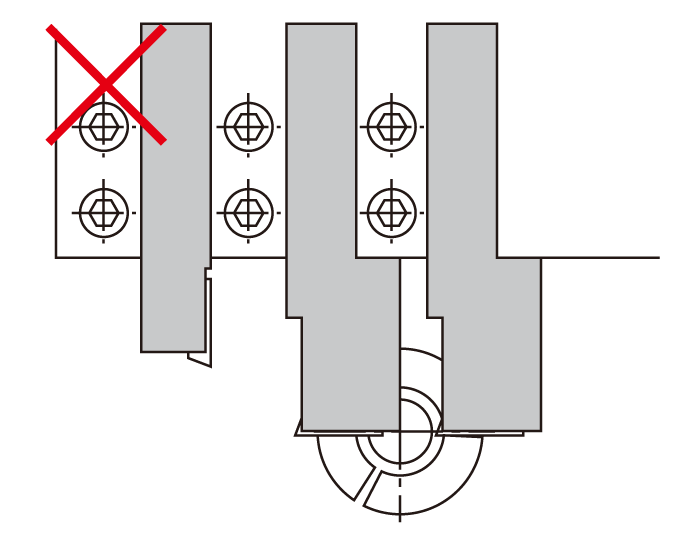

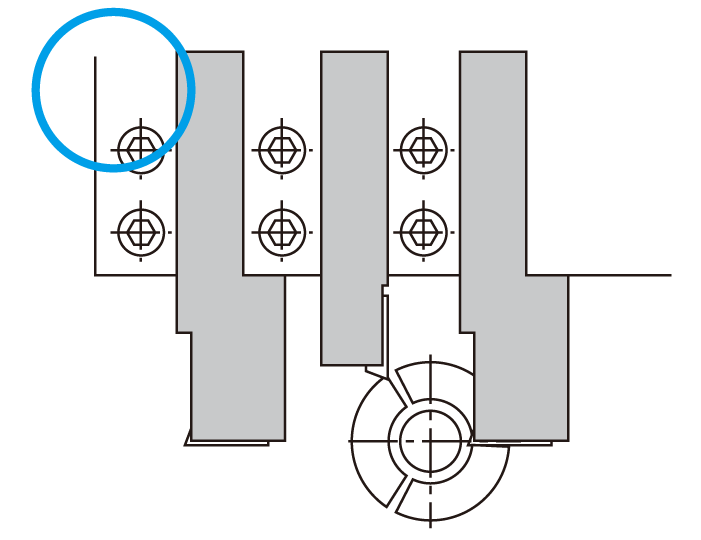

Use a maximum of 2 in vertical gang, and do not install side by side to prevent interference issues

The workpiece and Y-axis holder may interfere with each other

Typical positioning is sandwiching them in gang

When moving from tool No. ② to ④ , program retraction position based on the amount of y-axis holder overhang.

To ensure clearance, so y-axis holder in tool position ③ does not crash into workpiece.

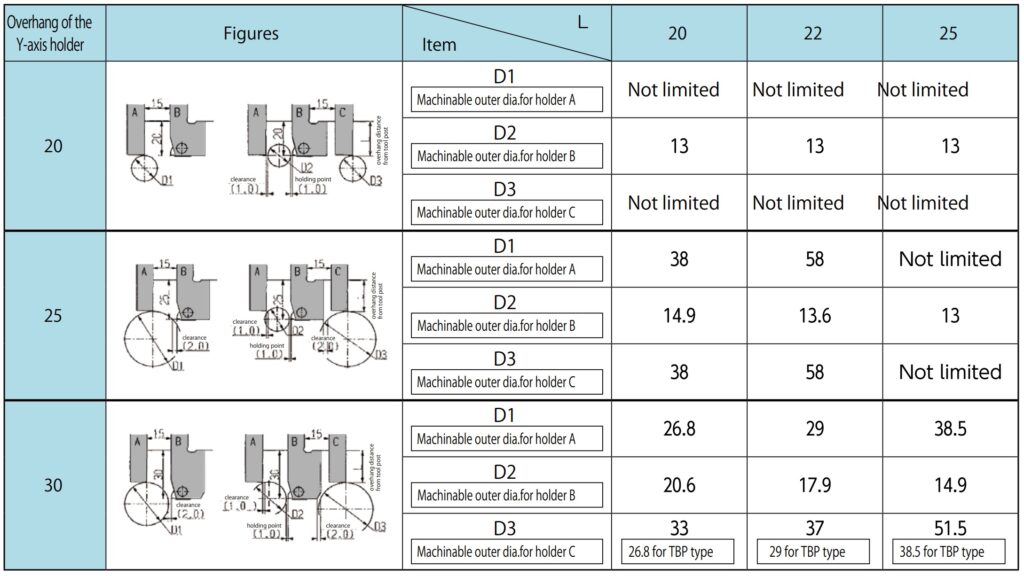

・Example uses Y-GTTR grooving holder to show holder and workpiece diameters in machine area

For more information about this product, visit our online e-catalog, or download the catalog/product report