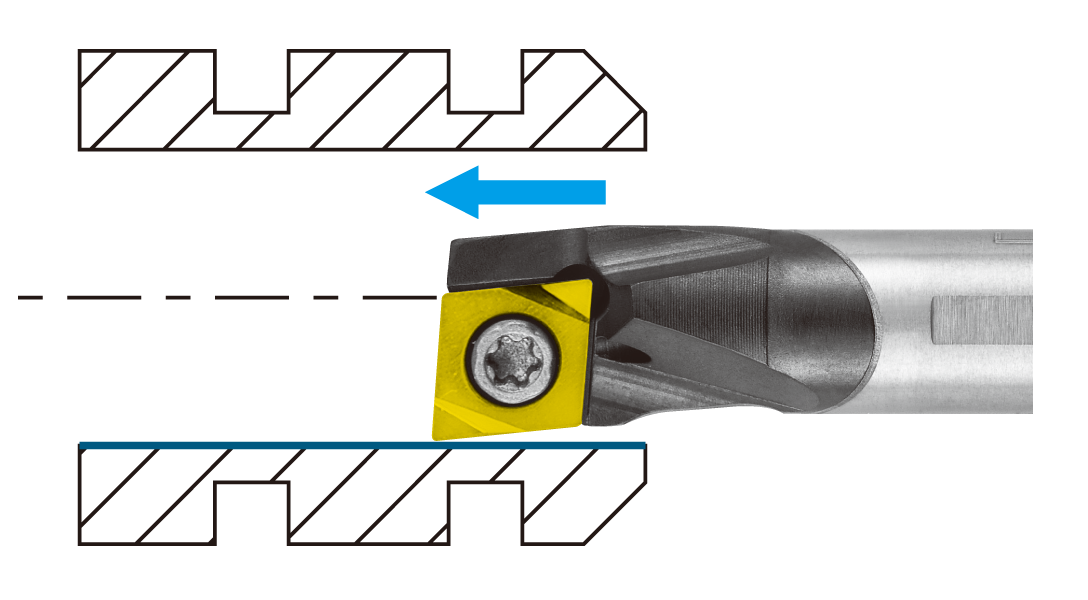

Successfully machines various workpiece materials.

Front turning / Back turning / Grooving / Cut off / ID boring / Socket machining / Milling

| Auto parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

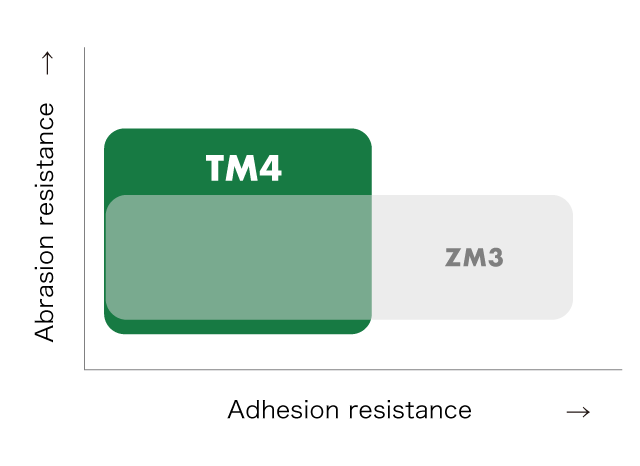

| TM4 |

950 pcs / corner

|

| Competitor’s PVD coated carbide |

500 pcs / corner

|

TM4 achieved 1.9 times longer tool life compared to the competitor’s insert with stability due to it’s excellent toughness.

| Auto parts | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| TM4 |

1,000 pcs / corner

|

| Competitor’s PVD coated carbide |

500 pcs / corner

|

For more information about this product, visit our online e-catalog, or download the catalog/product report