chipbreakerFor front turning operations | Swiss CNC Lathes

chipbreakerFor front turning operations | Swiss CNC Lathes

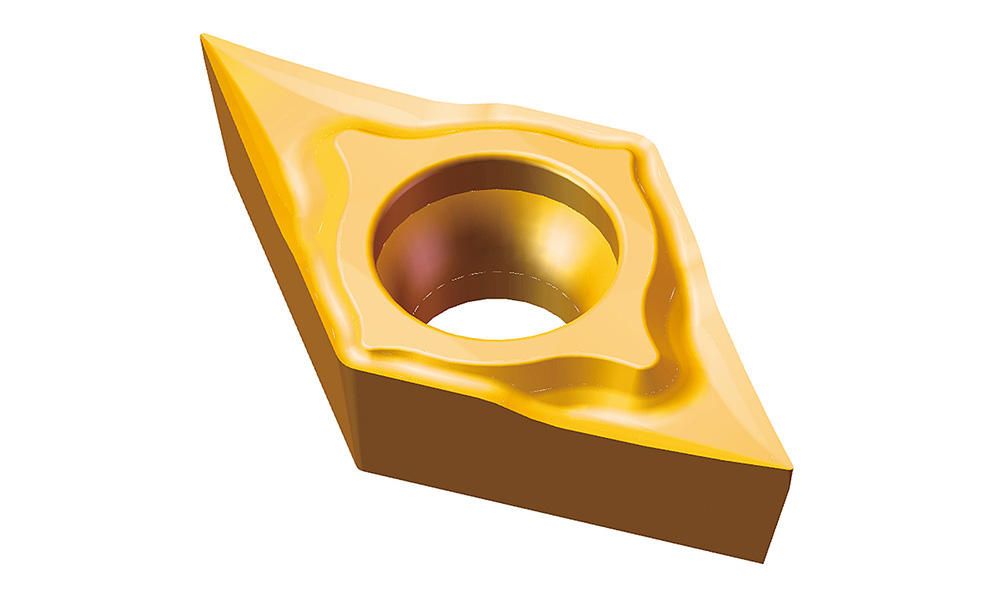

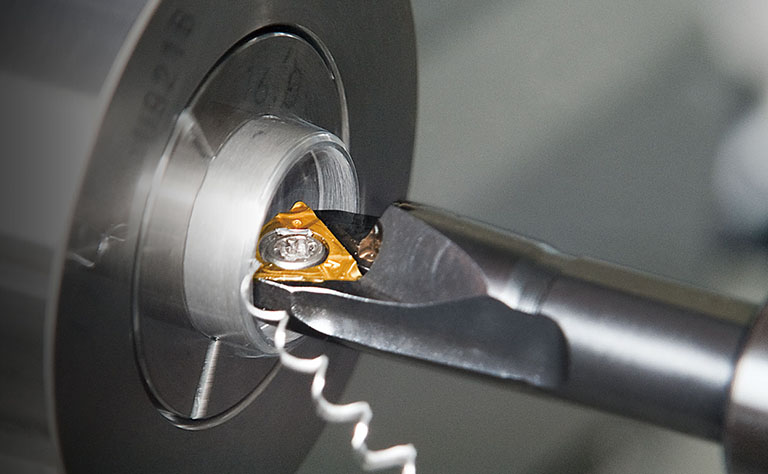

Sharpest molded chipbreaker

High-precision machining

Outstanding sharpness with less tool pressure

Product video

Features

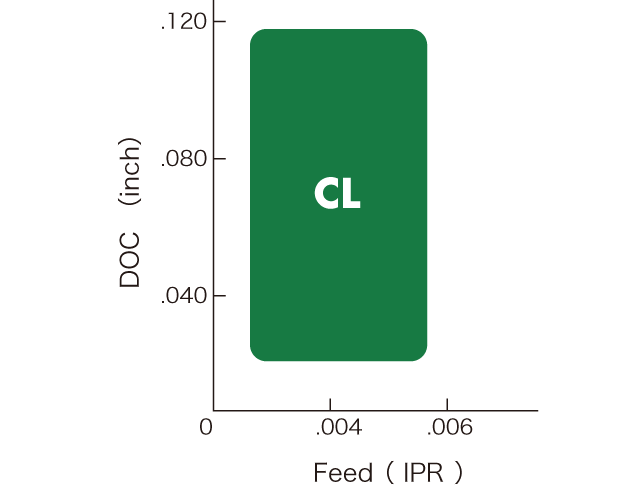

- Depth of cut range from .020 - .118 inch

- Sharp edge generates less tool pressure to reduce chatter and burrs

- Excellent chip control

Tooling application

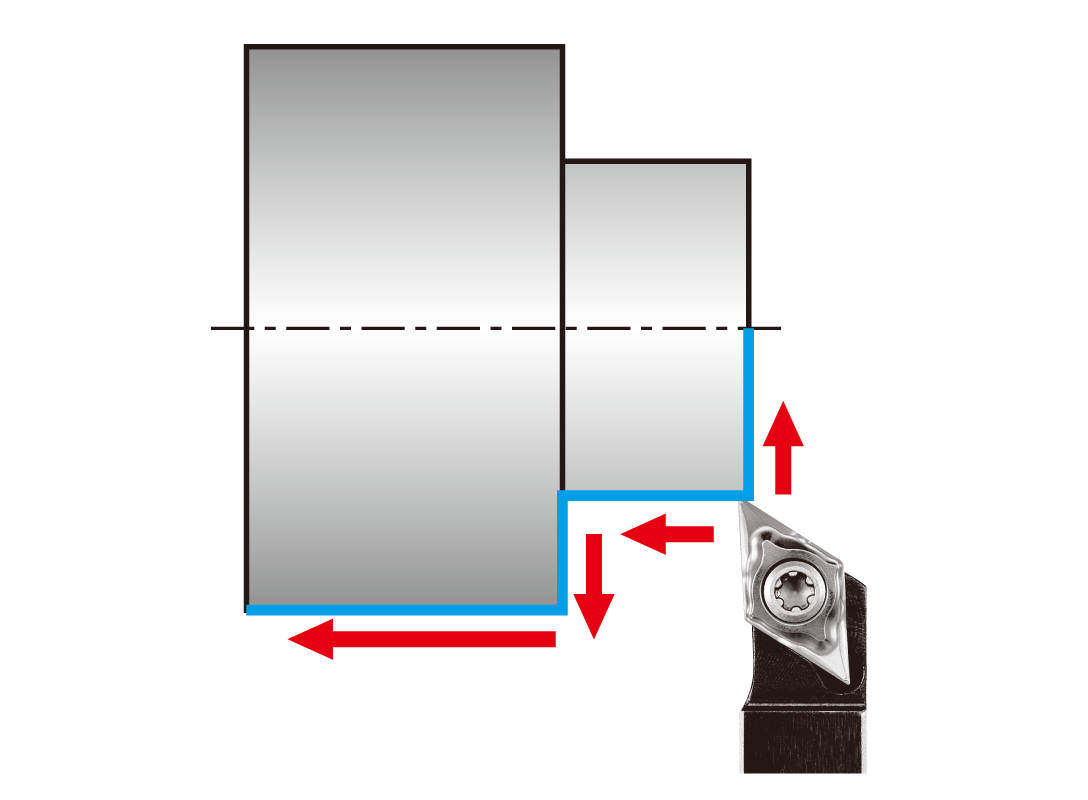

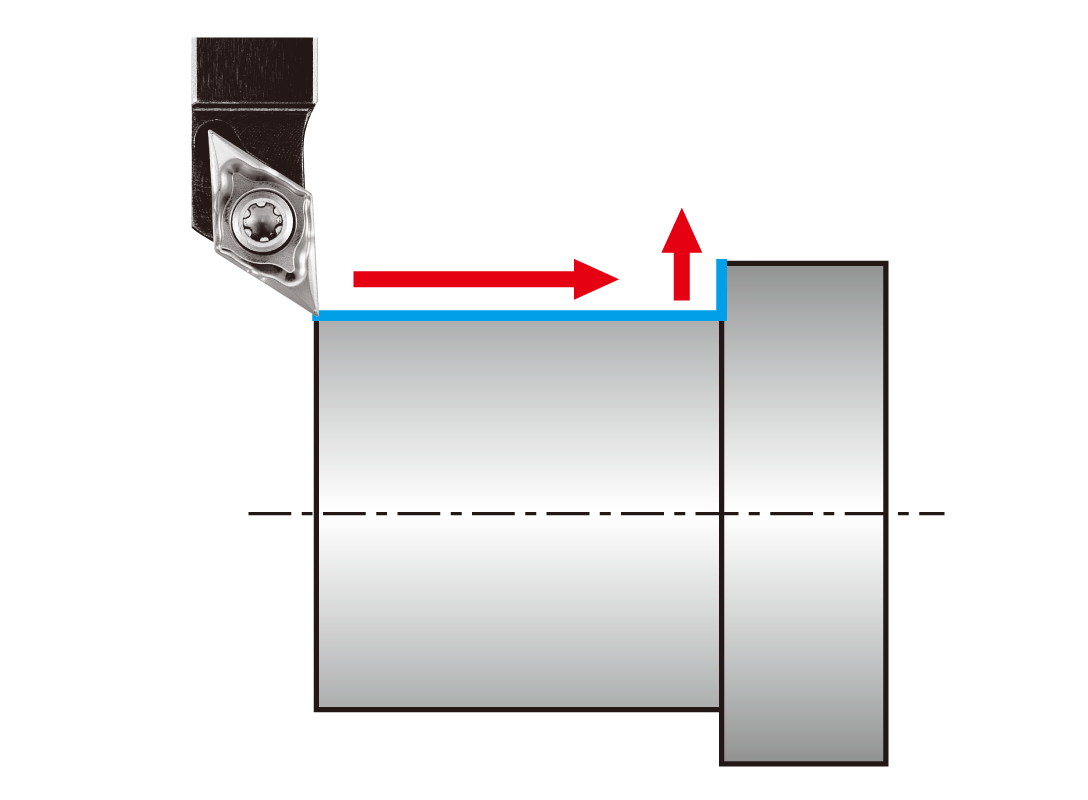

Swiss CNC Lathe front turning operations

CL chip breaker optimal functioning range

Cutting conditions

Scroll the table →

| Coated grade | Material | Operation type | Cutting speed (SFM) | Feed (IPR) | DOC (inch) |

|---|---|---|---|---|---|

| ST4 | Stainless | OD Turning continuous | 150 - 400 | .0008 - .004 | .020- .118 |

| QM3 | Alloy steel / carbon steel / hardened material | 150 - 500 | |||

| DM4/DT4 | Difficult-to-cut material / titanium alloy | 75 - 330 | |||

| TM4 | Non-ferrous / aluminum / plastic / general purpose | 150 - 600 |

Chipbreaker geometry

- High rake + sharp cutting edge reduces burr formation and increases machining accuracy

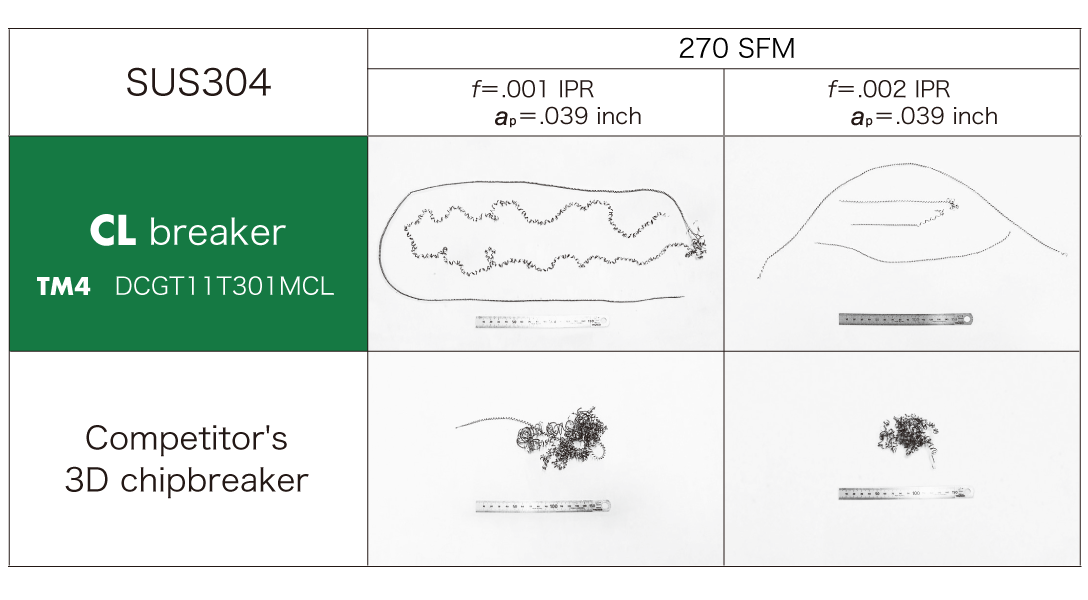

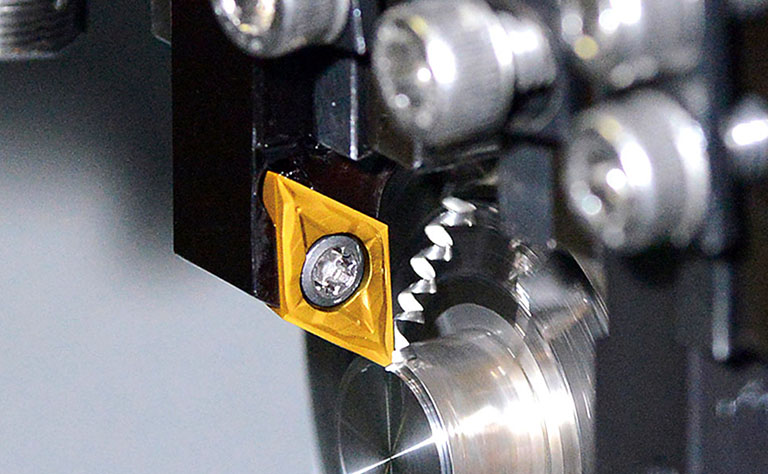

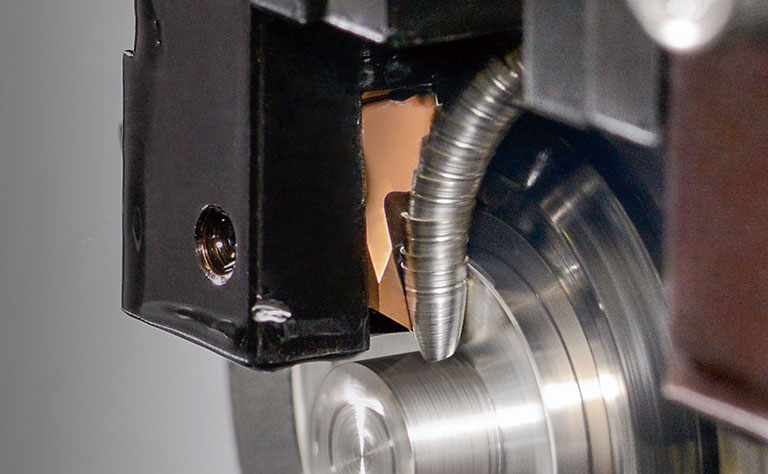

Chip formation comparison

Case study

| Connector | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| TM4 CL chipbreaker | 420 pcs / corner |

| Competitor's wiper insert (PVD coated carbide) |

300 pcs / corner |

CL chipbreaker achieved higher degree of dimensional stability and good surface finish compared to the competitor's polished insert.

CL chipbreaker demonstrated outstanding chip control even at the smaller DOC, eliminating machining issues.

| Pin | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| TM4 CL chipbreaker | 200 pcs / corner |

| Competitor's wiper insert (PVD coated carbide) |

100 pcs / corner |

CL chipbreaker achieved part dimensional consistency and extended tool life.

Stable chip control eliminated chip tangling seen using competitor's insert.

Tool lineup

Please check product catalog for tooling lineup

Other recommended products

-

YL chipbreakerFor front turning operations | Swiss CNC Lathes

First recommendation for front turning

-

S-MILLFor end milling| Swiss CNC lathes

NTK's unique design for sharpness

-

The Front MaxFor front turning operations | Swiss CNC Lathes

Single pass machining of up to .197" depth of cut

-

Mogul barsFor ID boring operations| Swiss CNC lathes

Solves common issues associated with ID boring operations

Useful information

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining

The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining

Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining "Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab

"Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab