Swiss CNC lathes End milling

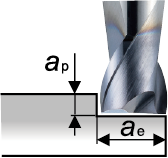

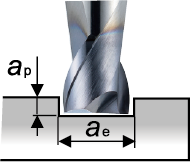

[ Cutting conditions ]

Material :

SUS304 Φ16.0 ap=3.0㎜ ae=1.2㎜ S = 3,000rpm F = 300㎜/min

304SS Φ.630” .118 DOC ae=.047 width S = 3,000rpm F = 11.8 IPM

[ Tools used ]

Φ6.0mm

Φ.236”

– 2 flute

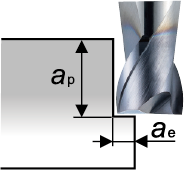

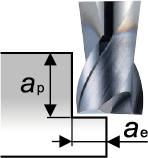

| Flute | φDc (mm) | Carbon steel | Alloy steel | Stainless steel |  ae = φDc × 0.2

ae = φDc × 0.2 |

ae = φDc × 0.5

ae = φDc × 0.5 |

ae = φDc × 0.75

ae = φDc × 0.75 |

ae = φDc × 0.9

ae = φDc × 0.9 |

ae = φDc

ae = φDc |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| rpm | IPM | rpm | IPM | rpm | IPM | ap (inch) | ae (inch) | ap (inch) | ae (inch) | ap (inch) | ae (inch) | ap (inch) | ae (inch) | ap (inch) | ||

| 2 flute | 2.0 | 14,300 | 9.1 | 11,100 | 7.1 | 10,300 | 5.5 | ≦.079 | .016 | ≦.031 | .039 | ≦.024 | .059 | ≦.020 | .071 | ≦.016 |

| 3.0 | 9,500 | 13.0 | 7,400 | 10.2 | 6,900 | 8.3 | ≦.118 | .024 | ≦.047 | .059 | ≦.035 | .091 | ≦.028 | .106 | ≦.024 | |

| 4.0 | 7,200 | 15.4 | 5,600 | 11.8 | 5,200 | 9.4 | ≦.157 | .031 | ≦.063 | .079 | ≦.047 | .118 | ≦.039 | .142 | ≦.031 | |

| 5.0 | 5,700 | 16.5 | 4,500 | 13.0 | 4,100 | 10.2 | ≦.197 | .039 | ≦.079 | .098 | ≦.059 | .150 | ≦.047 | .177 | ≦.039 | |

| 6.0 | 4,800 | 17.3 | 3,700 | 13.4 | 3,400 | 10.6 | ≦.236 | .047 | ≦.094 | .118 | ≦.071 | .177 | ≦.059 | .213 | ≦.047 | |

| 7.0 | 4,100 | 16.5 | 3,200 | 13.0 | 3,000 | 10.6 | ≦.236 | .055 | ≦.110 | .138 | ≦.083 | .209 | ≦.067 | .248 | ≦.055 | |

| 8.0 | 3,600 | 16.1 | 2,800 | 12.6 | 2,600 | 9.8 | ≦.236 | .063 | ≦.126 | .157 | ≦.094 | .236 | ≦.079 | .283 | ≦.063 | |

| 10.0 | 2,900 | 14.6 | 2,200 | 11.0 | 2,100 | 9.1 | ≦.236 | .079 | ≦.157 | .197 | ≦.118 | .295 | ≦.098 | .354 | ≦.079 | |

| 3 flute | 3.0 | 9,500 | 15.4 | 7,400 | 12.2 | 6,900 | 9.8 | ≦.118 | .315 | ≦.047 | .059 | ≦.035 | .091 | ≦.028 | .106 | ≦.024 |

| 4.0 | 7,200 | 18.5 | 5,600 | 14.2 | 5,200 | 11.4 | ≦.157 | .031 | ≦.063 | .079 | ≦.047 | .118 | ≦.039 | .142 | ≦.031 | |

| 5.0 | 5,700 | 19.7 | 4,500 | 15.7 | 4,100 | 12.2 | ≦.197 | .039 | ≦.079 | .098 | ≦.059 | .150 | ≦.047 | .177 | ≦.039 | |

| 6.0 | 4,800 | 20.9 | 3,700 | 16.1 | 3,400 | 13.0 | ≦.236 | .047 | ≦.094 | .118 | ≦.071 | .177 | ≦.059 | .213 | ≦.047 | |

| 7.0 | 4,100 | 20.1 | 3,200 | 15.7 | 3,000 | 12.6 | ≦.236 | .055 | ≦.110 | .138 | ≦.083 | .209 | ≦.067 | .248 | ≦.055 | |

| 8.0 | 3,600 | 19.3 | 2,800 | 15.0 | 2,600 | 12.2 | ≦.236 | .063 | ≦.126 | .157 | ≦.094 | .236 | ≦.079 | .283 | ≦.063 | |

| 10.0 | 2,900 | 17.3 | 2,200 | 13.0 | 2,100 | 11.0 | ≦.236 | .079 | ≦.157 | .197 | ≦.118 | .295 | ≦.098 | .354 | ≦.079 | |

| 4 flute | 3.0 | 9,500 | 18.1 | 7,400 | 14.2 | 6,900 | 11.4 | ≦.118 | .024 | ≦.047 | .059 | ≦.035 | .091 | ≦.028 | .106 | ≦.024 |

| 4.0 | 7,200 | 21.3 | 5,600 | 16.5 | 5,200 | 13.4 | ≦.157 | .031 | ≦.063 | .079 | ≦.047 | .118 | ≦.039 | .142 | ≦.031 | |

| 5.0 | 5,700 | 23.2 | 4,500 | 18.1 | 4,100 | 14.6 | ≦.197 | .039 | ≦.079 | .098 | ≦.059 | .150 | ≦.047 | .177 | ≦.039 | |

| 6.0 | 4,800 | 24.4 | 3,700 | 18.9 | 3,400 | 15.0 | ≦.236 | .047 | ≦.094 | .118 | ≦.071 | .177 | ≦.059 | .213 | ≦.047 | |

| 7.0 | 4,100 | 23.2 | 3,200 | 18.1 | 3,000 | 15.0 | ≦.236 | .055 | ≦.110 | .138 | ≦.083 | .209 | ≦.067 | .248 | ≦.055 | |

| 8.0 | 3,600 | 22.4 | 2,800 | 17.3 | 2,600 | 14.2 | ≦.236 | .063 | ≦.126 | .157 | ≦.094 | .236 | ≦.079 | .283 | ≦.063 | |

| 10.0 | 2,900 | 20.1 | 2,200 | 15.4 | 2,100 | 12.6 | ≦.236 | .079 | ≦.157 | .197 | ≦.118 | .295 | ≦.098 | .354 | ≦.079 | |

Cutting conditions (machine, work material…) affect surface finish and burr generation. If cutting performance is not good with above cutting conditions, please adjust speed and feed by same ratio.

| φ6mm φ.236” – 2 flute D-Cut | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| S-MILL |

12,000 pcs / corner+α

|

| Competitor’s solid endmill |

10,000 pcs / corner

|

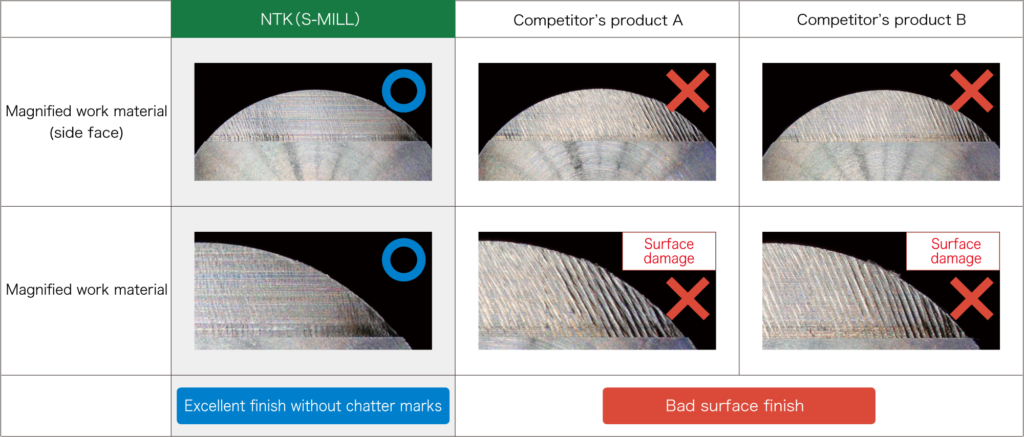

The competitor’s end mill showed an obvious decrease in surface finish quality as it reached the end of its tool life.

The S-Mill maintained a quality finish throughout the extent of its long tool life.

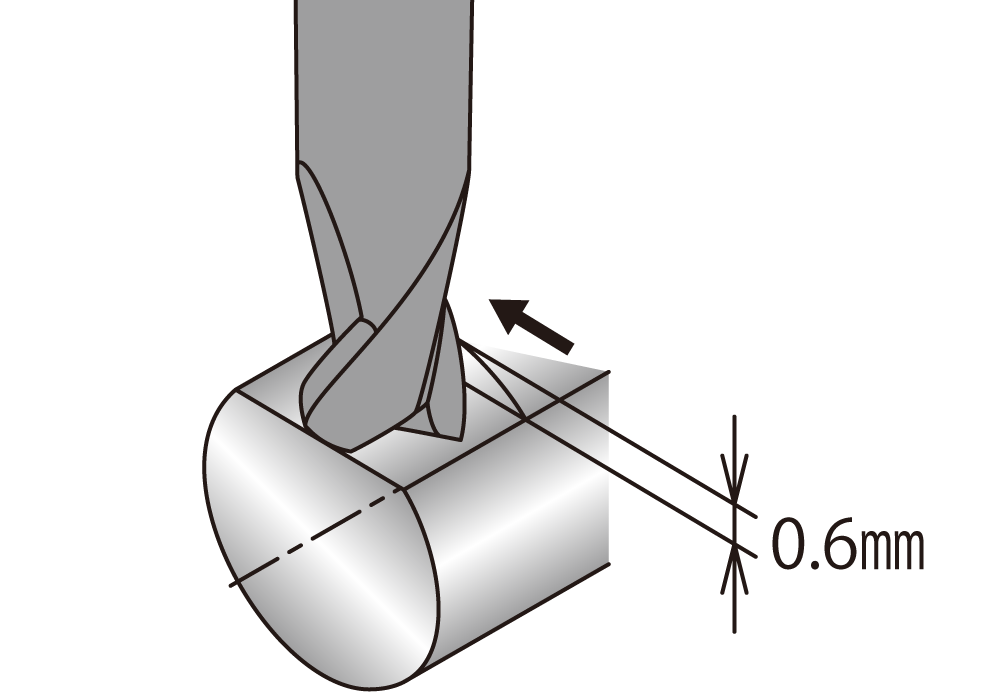

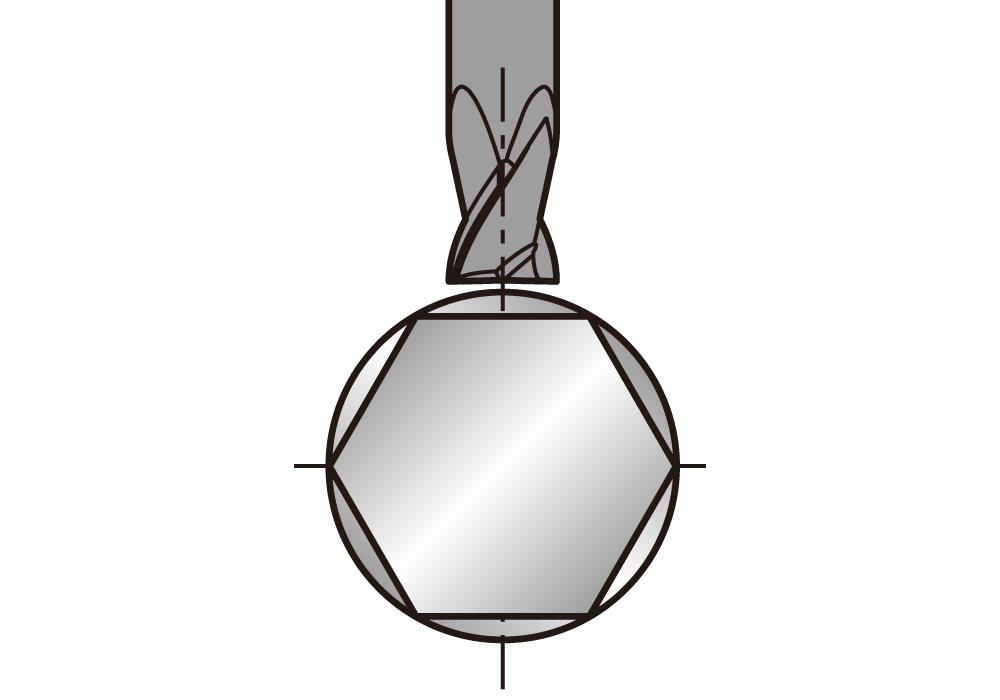

| φ6mm – 2 flute φ10mm → AF 8mm φ.236” – 2 flute φ.394” → AF .315” hexagon | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| S-MILL |

70 pcs / corner+α

|

| Competitor’s solid endmill |

50 pcs / corner

|

The S-Mill’s sharpness reduced the occurrence of burrs and increased tool life compared to competitor’s tool.

The sharp cutting edge also produced noticeably less sound than the current tool.

For more information about this product, visit our online e-catalog, or download the catalog/product report