For cut-off operations with max. diameter up to 16mm .630” | Swiss CNC lathes

Swiss CNC lathe cut-off operations

| Maximum cut-off diamter | ||||||

| Coated grade | Material | Operation type | Cutting speed (m/min) Cutting speed (SFM) | Feed (mm/rev) Feed (IPR) | CTP type | CTPA type |

|---|---|---|---|---|---|---|

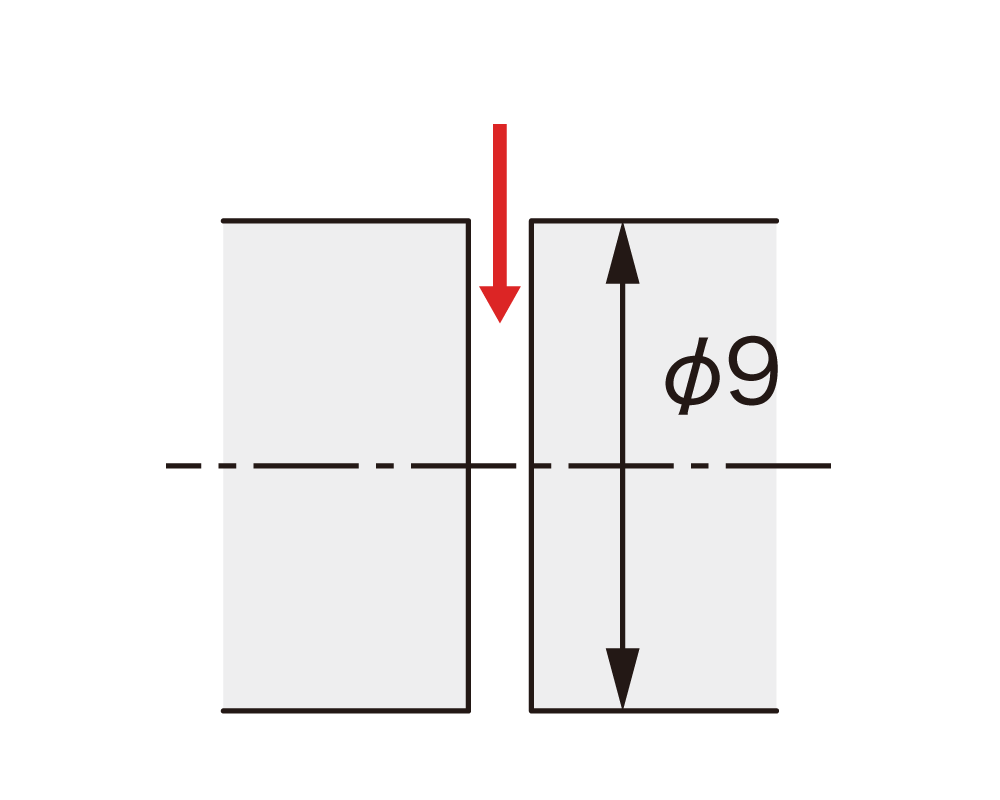

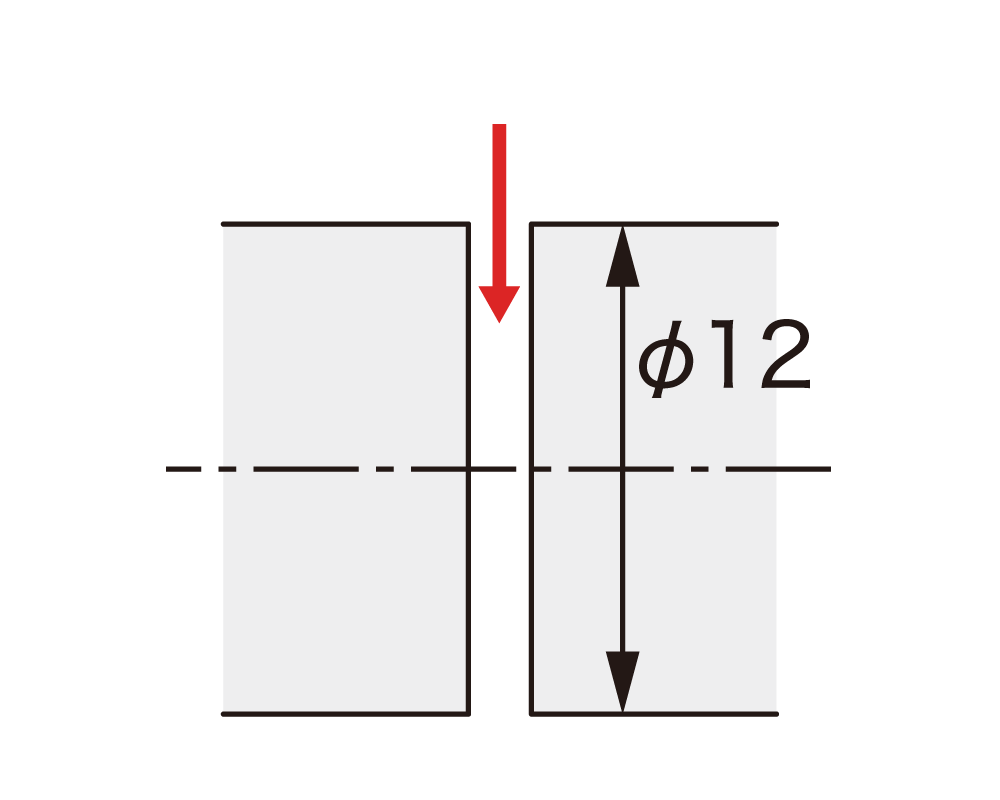

| ST4 | Stainless | Cut off | 40 – 100 100 – 230 | 0.02 – 0.06 .0008 – .0025 | ⌀12 ⌀.472” | ⌀16 ⌀.630” |

| DM4 | Difficult-to-cut material / titanium alloy / high temp alloys | 50 – 70 100 – 230 | ||||

| Alloy steel / carbon steel / hardened material / general purpose | 50 – 90 100 – 300 | |||||

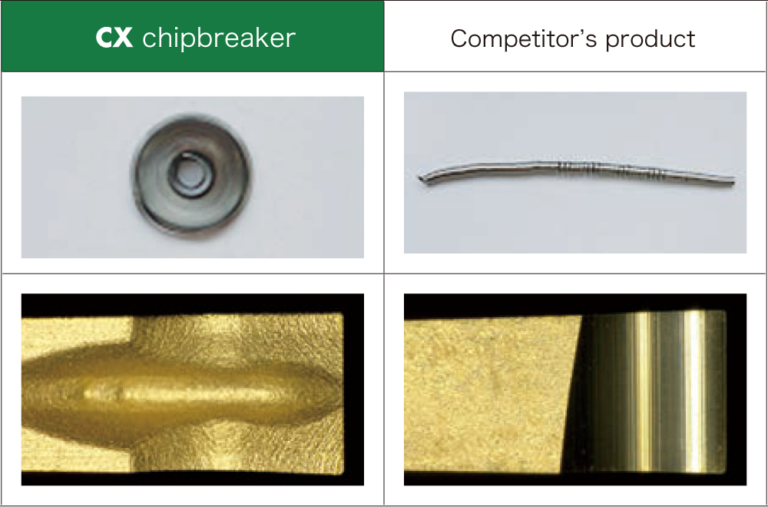

[ Cutting conditions ]

Material :

SUS304 ⌀8 vc=80m/min

304SS ⌀.315 270 sfm

WET

[ Tools used ]

Holder : CTPR12 Insert : DM4CTP15FRN-CX

| Shaft | |

|---|---|

|

|

|

|

|

|

|

|

| CX chipbreaker DM4 CTPA15FRN-CX |

5,000 pcs / corner

|

| Competitor’s wiper insert |

2,000 pcs / corner

|

Competitor’s insert edge chipped resulting in a rough machined surface.

The CX insert maintained a good cutting edge resulting in stable machining, smooth machined surface, and long tool life.

| Sleeve | |

|---|---|

|

|

|

|

|

|

|

|

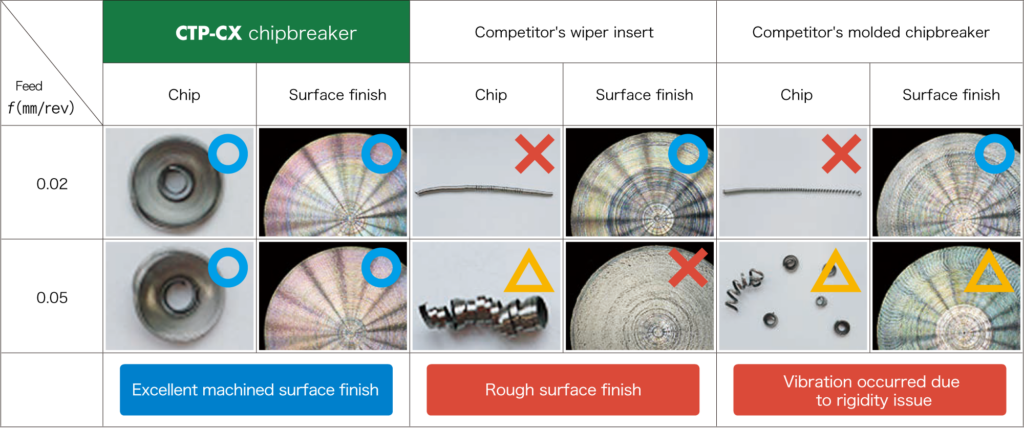

| CX chipbreaker ST4 CTP15FLN-CX |

3,500 pcs / corner

|

| Competitor’s molded chipbreaker (PVD coated carbide) |

2,000 pcs / corner

|

The CX chipbreaker achieved stable machining and controlled the chip and evacuated it away from the part.

The ST4 grade is best for stainless steel materials which extended tool life by 1.5 times compared to the competitor’s insert.

For more information about this product, visit our online e-catalog, or download the catalog/product report