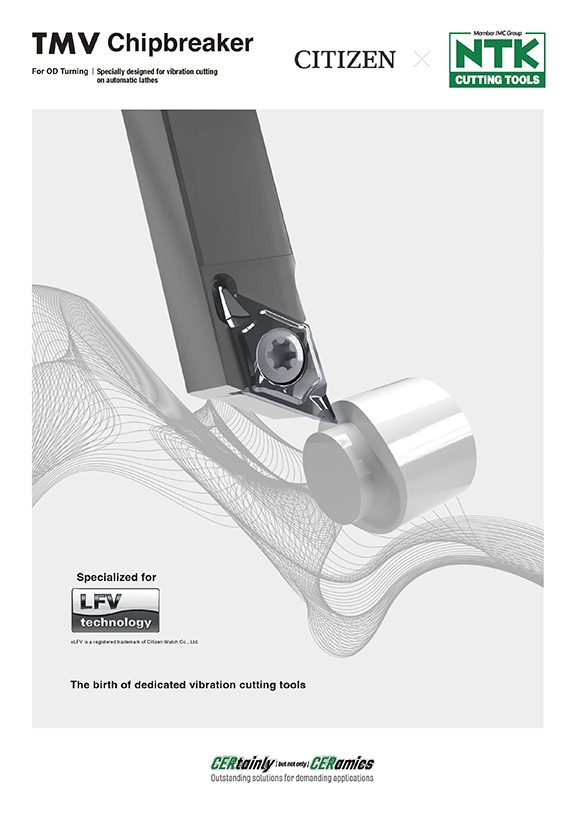

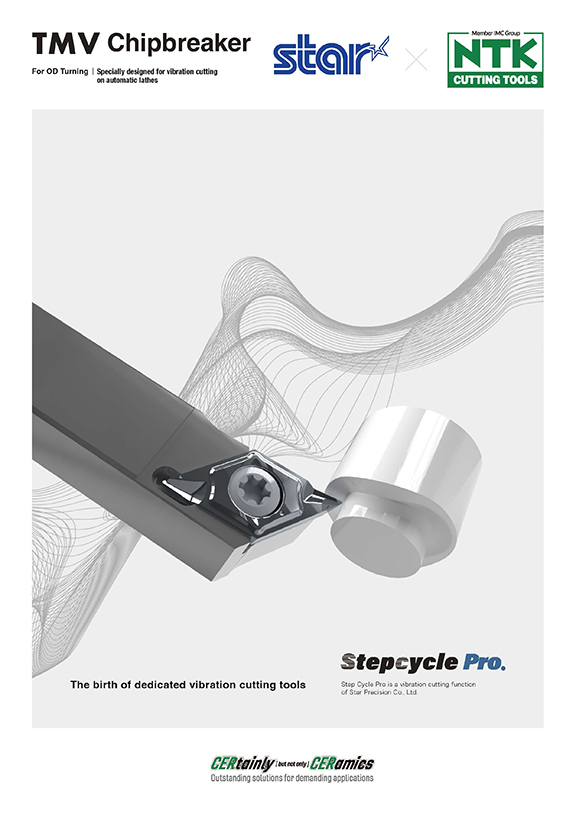

ChipbreakerFor Front Turning | Designed for Vibration Cutting on Swiss CNC Machines

ChipbreakerFor Front Turning | Designed for Vibration Cutting on Swiss CNC Machines

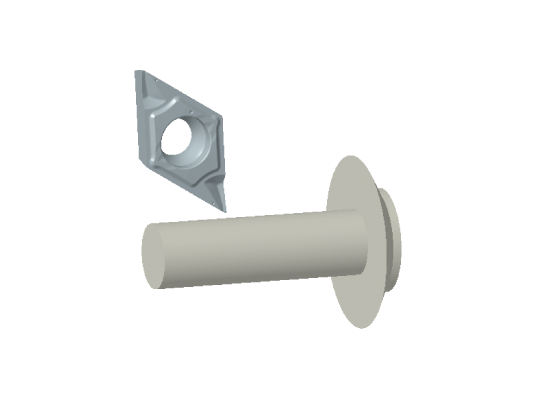

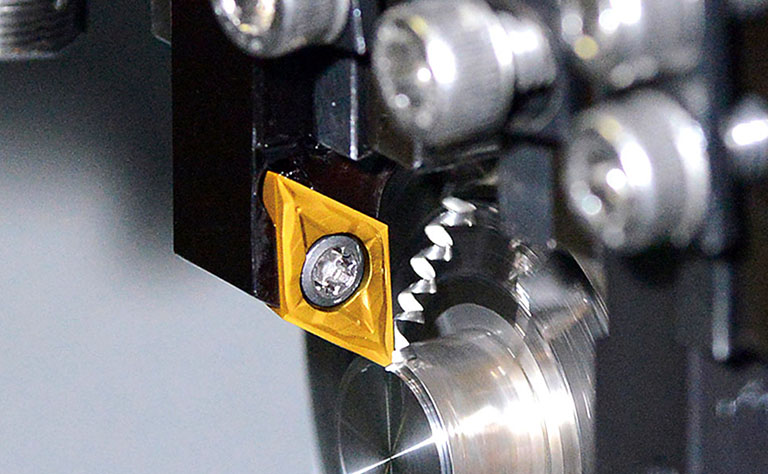

Dedicated Tools for Vibration Cutting

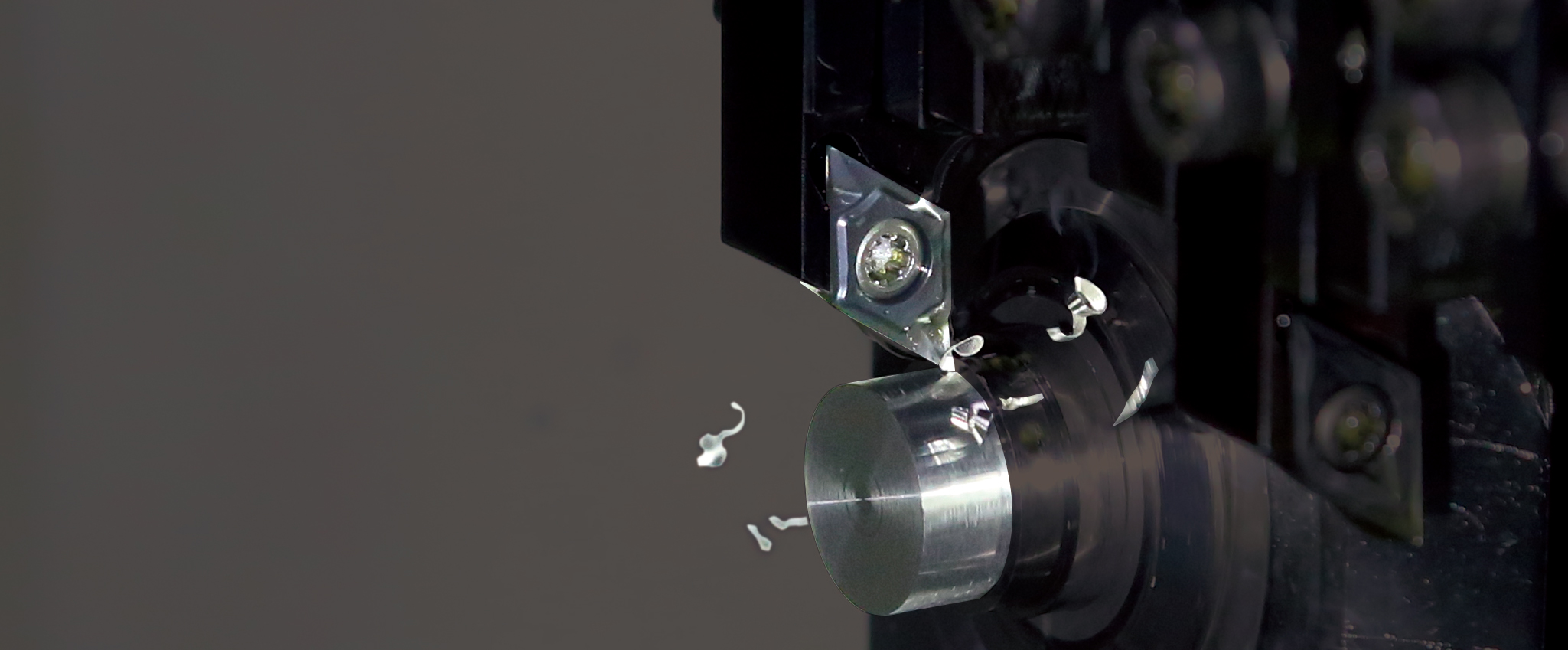

Reliably long tool life and stable chip evacuation during vibration cutting

The development of a cutting tool that delivers maximum performance during vibration cutting utilization.

NTK provides the best choice and eliminates the guess work of selecting a tool.

Performance

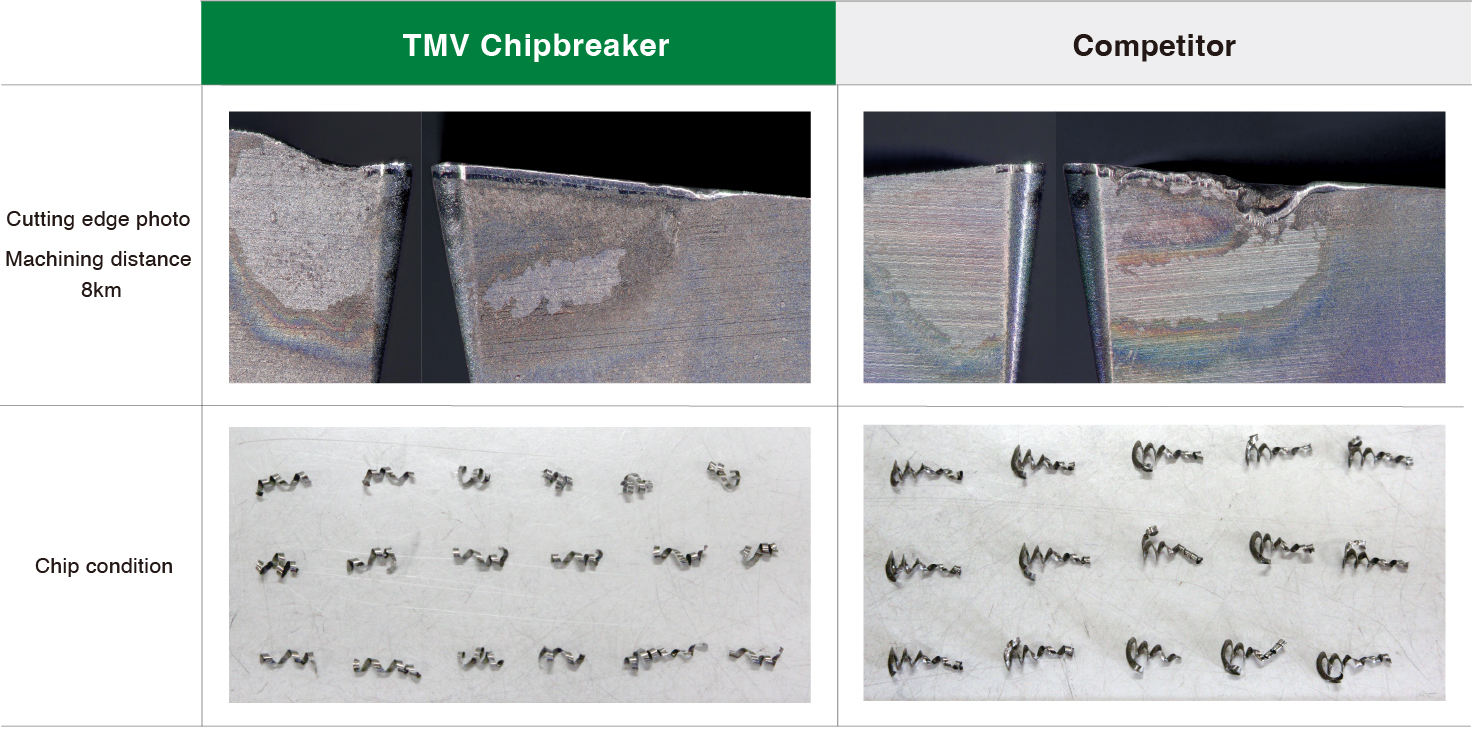

- Dramatic reduction in cutting edge wear

Extended tool life even machining difficult-to cut materials - Stable chip removal with dramatic reduction in cutting edge wear

Stable chip formation during vibration cutting

Applications

Front turning operations on swiss cnc using vibration cutting function

- [ Cutting conditions ]

- Work material:316LSS 270 SFM ap = .040″ .001 IPR Mode1 D1.5 Q1.5 ( LFV )

Machining conditions

Scroll the table →

| Grade | Work materials | Operation | Cutting conditions | ||

|---|---|---|---|---|---|

| Cutting speed (SFM) | Feed (IPR) | D.O.C. (inch) | |||

| ST4 | Austenitic stainless steel ( 304SS / 316SS etc ) |

Front turning | 130 - 330 | .0008 - .0024 | .02 - .08 |

| DM4 | Carbon steel / Alloy steel ( S45C / SCM435 etc ) | Front turning | 170 - 400 | .0008 - .0024 | |

| TM4 | Non-ferrous ( Aluminum / Titanium etc ) | Front turning | 200 - 500 | .0008 - .0024 | |

⚠ Our products are designed with a low cutting edge, please use them after aligning with the center.

⚠ When using insert radius R.003, please set the feed rate to .0008″/rev or less. If you want to increase the feed rate beyond .0008″/rev, we recommend using the [ Mode 2 / E4.0 / R0.5 ]

| CITIZEN MACHINERY CO., LTD. Vibration condition ( LFV ) | ||

|---|---|---|

| P | Q | D |

| Mode 1 | 0.5 | 0.5 |

⚠ Our products are designed with a low cutting edge, please use them after aligning with the center.

⚠ When using insert radius R.003, please set the feed rate to .0008″/rev or less. If you want to increase the feed rate beyond .0008″/rev, we recommend using the [ Mode 2 / E4.0 / R0.5 ]

| Star precision Co., Ltd. Vibration Conditions (Step Cycle Pro) | |

|---|---|

| A (Chip length factor) | D (Amplitude factor) |

| More than 2.0 | More than 2.0 |

⚠ Our products are designed with a low cutting edge, please use them after aligning with the center.

⚠ When using insert radius R0.08, please set the feed rate to .0008″/rev or less.

Case Study

| CNC Lathe | Cincom L20-LFV |

| Work material | 316LSS |

| Cutting speed | 270 SFM |

| Feed | .002 IPR |

| D.O.C. (ap) | .040″ |

| Coolant | WET |

| Vibration condition | Mode 1 Q0.5 D0.5 |

* Materials other than stainless steel are currently being validated

| Construction machine parts | |

|---|---|

|

Machining dia. :φ.31″ / .425″ / .472″ Machining dia. :φ.31″ / .425″ / .472″ |

|

|

|

|

|

|

|

|

| DM4 DCGT11T302MRTMV | 600pcs / corner |

| Competitor’s PVD carbide | 300pcs / corner |

| Valve parts | |

|---|---|

|

Machining dia. φ.15″ Machining dia. φ.15″ |

|

|

|

|

|

|

|

|

| ST4 DCGT11T302MRTMV | 3,000pcs / corner |

| Competitor’s PVD carbide | 2,200pcs / corner |

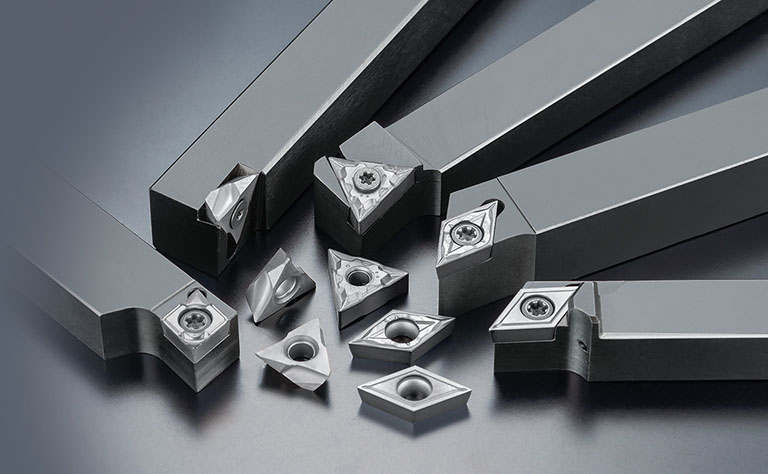

Lineup

Scroll the table →

| Shape | Item description | Quantity/Case | Grade (PVD) | Dimensions | |||||

|---|---|---|---|---|---|---|---|---|---|

| ISO | ANSI | ST4 | DM4 | TM4 | IC | Thickness | Radius | ||

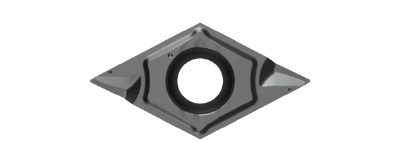

|

DCGT11T301MRTMV | DCGT32.504MRTMV | 10 | ● | ● | ● | 3/8 | 5/32 | .003 * |

| DCGT11T302MRTMV | DCGT32.508MRTMV | 10 | ● | ● | ● | 3/8 | 5/32 | .007 | |

| DCGT11T304MRTMV | DCGT32.51MRTMV | 10 | ● | ● | ● | 3/8 | 5/32 | .015 | |

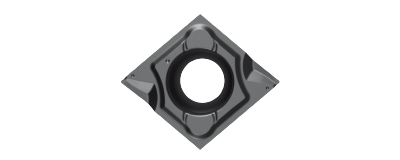

|

CCGT09T301MRTMV | CCGT32.504MRTMV | 10 | ● | ● | ● | 3/8 | 5/32 | .003 * |

| CCGT09T302MRTMV | CCGT32.508MRTMV | 10 | ● | ● | ● | 3/8 | 5/32 | .007 | |

| CCGT09T304MRTMV | CCGT32.51MRTMV | 10 | ● | ● | ● | 3/8 | 5/32 | .015 | |

|

VCGT110302MRTMV | VCGT2208MRTMV | 10 | ● | ● | ● | 1/4 | 1/8 | .007 |

| VCGT110304MRTMV | VCGT221MRTMV | 10 | ● | ● | ● | 1/4 | 1/8 | .015 | |

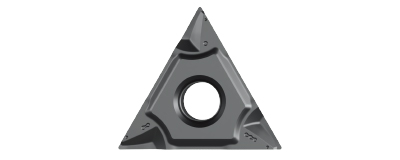

|

TNGG160402MRTMV | TNGG3308MRTMV | 10 | ● | ● | ● | 3/8 | 3/16 | .007 |

| TNGG160404MRTMV | TNGG331MRTMV | 10 | ● | ● | ● | 3/8 | 3/16 | .015 | |

⚠ Our products are designed with a low cutting edge, please use them after aligning with the center.

⚠ When using insert radius R.003, please set the feed rate to .0008″/rev or less. If you want to increase the feed rate beyond .0008″/rev, we recommend using the [ Mode 2 / E4.0 / R0.5 ]

Continued validation and expansion of product lineup to include other part materials

Encourage customer suggestions and support to drive new product development that is focused on solutions

View Catalog Information

Product video

Other recommended products

-

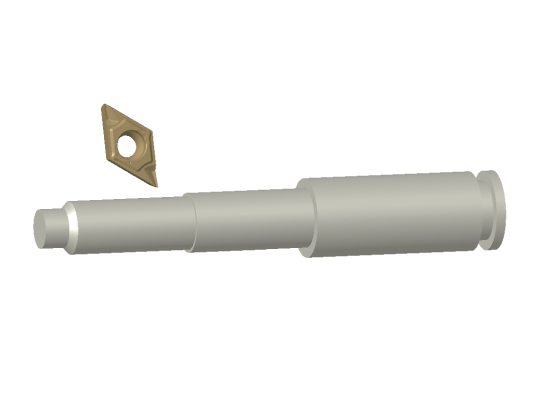

SPLASH seriesCoolant through toolholders | Swiss CNC Lathes

Extensive selection of styles and sizes

-

YL chipbreakerFor front turning operations | Swiss CNC Lathes

First recommendation for front turning

-

ST4Best grade for machining stainless steel | Carbide grade for Swiss CNC lathes

Having issues machining stainless steel ? - Problem solved

-

SHAPER DUOFor socket hole machining| Swiss CNC lathes

Highly productive socket hole machining

Useful information

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining

4 STEP-NTK Cutting Tools Lab for choosing suitable cutting tool for cut-off machining The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining

The aspects of "chip control" that you should check when workpiece damage or poor dimensioning are detected during Swiss type CNC automatic lathe machining Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining

Two Areas to Check When Coaxiality is Not Achieved During Swiss CNC Lathe Machining "Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab

"Two" checkpoints and measures to be checked when "Roundness" does not come out in Swiss-type CNC-automatic lathe machining-NTK Cutting Tools Lab