| Series | Features | DC | KAPR | APMX |

|---|---|---|---|---|

| mm inch | ° | mm inch | ||

| JWNXM series | Low resistance × multiple corners

|

⌀63 – 160 2.48 – 6.23 | 88° | -5.5 -.217 |

|

||||

| JFDX series | Low cost × versatility

|

⌀63 – 160 2.48 – 6.23 | 45°,75°,88° | -6 -.240 |

|

||||

| JXTM series | High rigidity

|

⌀80 – 125 3.15 – 4.921 | 88° | -8 -.315 |

|

||||

| JQ series | Shoulder milling × Small diameter cutter

|

⌀20 – 80 .787 – 3.15 | 90° | -8 -.315 |

-300x185.jpg) |

||||

| JSDW series | Low tool pressure

|

⌀80 – 160 3.15 – 6.23 | 45°,75° | -6 -.240 |

|

Features

| Work material | Application | Purpose | Cutting speed(m/min) Cutting speed(SFM) | Feed(mm/rev) Feed(IPR/IPT) | Depth of cut(mm) Depth of cut(inch) | DRY | WET |

|---|---|---|---|---|---|---|---|

| Cast iron | Milling | Rough | 450 – 1200 1500–4200 | 0.07 – 0.2 .003–.010 | 0.5 – 3.5 .020–.140 | ● | ● |

Features

| Work material | Application | Purpose | Cutting speed (m/min) Cutting speed(SFM) | Feed(mm/rev) Feed(IPR/IPT) | Depth of cut(mm) Depth of cut(inch) | DRY | WET |

|---|---|---|---|---|---|---|---|

| Gray cast iron | Milling | Rough–Semi finish | 350 – 700 1200–2500 | 0.07 – 0.25 .003–.010 | -6.0 –.240 | ● | ○ |

| Ductile cast iron | Milling | Rough–Semi finish | 400 – 800 2100–3000 | 0.07 – 0.25 .003–.010 | -6.0 –.240 | ● | ○ |

Features

Features

| Cutter Item number | Mountable standard | ||

|---|---|---|---|

| Type of standard arbor | Arbor diameter | ||

| JWNXM | ⌀63 2.5 | FMC | ⌀22.0 .087 |

| ⌀80 3.0 | FMA | ⌀25.4 1 | |

| ⌀100 4.0 | FMA | ⌀31.75 1.25 | |

| ⌀125 5.0 | FMA | ⌀38.1 1.5 | |

| ⌀160 6.0 | FMA | ⌀50.8 2 | |

| JFDX | ⌀63 2.5 | FMC | ⌀22.0 .087 |

| ⌀80 3.0 | FMA | ⌀25.4 1 | |

| ⌀100 4.0 | FMA | ⌀31.75 1.25 | |

| ⌀125 5.0 | FMA | ⌀38.1 1.5 | |

| JSDW | ⌀63 2.5 | FMC | ⌀22.0 .087 |

| ⌀80 3.0 | FMA | ⌀25.4 1 | |

| ⌀100 4.0 | FMA | ⌀31.75 1.25 | |

| ⌀125 5.0 | FMA | ⌀38.1 1.5 | |

| JXTM | ⌀80 3.0 | FMA | ⌀25.4 1 |

| ⌀100 4.0 | FMA | ⌀31.75 1.25 | |

| ⌀125 5.0 | FMA | ⌀38.1 1.5 | |

| JQTS | ⌀40 1.6 | ⌀16.0 0.63 | |

| ⌀50 2.0 | FMC | ⌀22.0 .087 | |

| ⌀63 2.5 | FMC | ⌀22.0 .087 | |

| JQTE | ⌀20 0.8 ※ | ⌀20 0.8” Gripping diameter sleeve ※ | Shank diameter ⌀20 0.8” ※ |

| ⌀25 1.0 ※ | ⌀25 1.0” Gripping diameter sleeve ※ | Shank diameter ⌀25 1.0” ※ | |

| ⌀32 1.3” ※ | ⌀32 1.3” Gripping diameter sleeve ※ | Shank diameter ⌀32 1.3” ※ | |

| ⌀40 1.6 ※ | ⌀32 1.3” Gripping diameter sleeve ※ | Shank diameter ⌀32 1.3” ※ | |

※Shank-type body

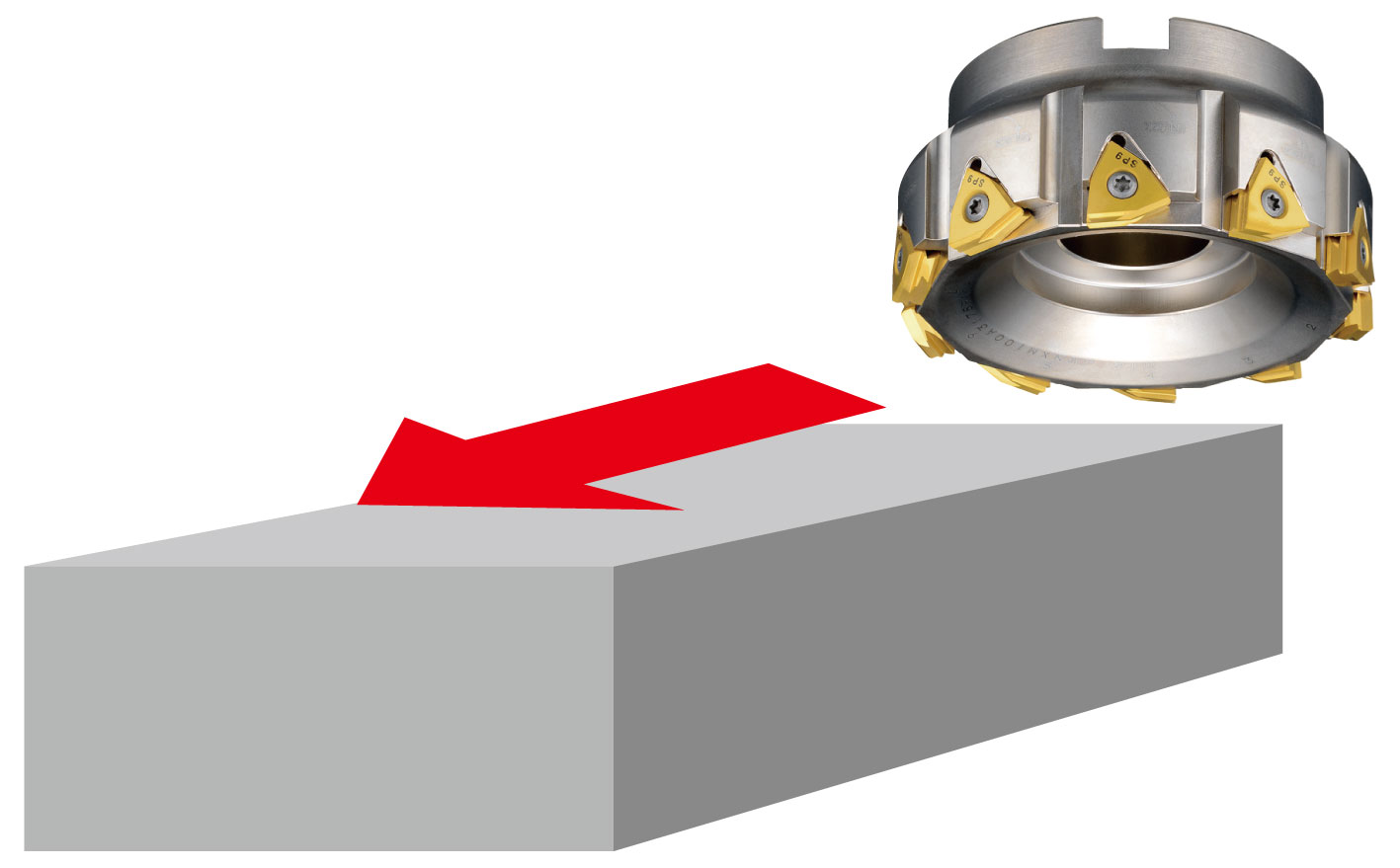

| Milling Application | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

|

||

| SX6 |

360 pcs / corner

|

|

| Competitor’s carbide inserts |

260 pcs / corner

|

|

High-speed milling with ceramic significantly reduced cycle time compared to the current carbide inserts. (Single pass process went from 40 min. down to 15min.) SX6 achieved 1.4 times more tool life.

Tooling costs are reduced by utilizing negative inserts, increasing the number of corners.

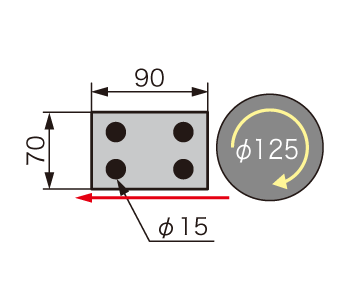

| Transmission Case Cover | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

|

||

|

||

|

||

| SX6 |

1.3 min |

|

| Competitor’s carbide inserts |

5.4 min |

|

Compared to current carbide inserts, high-speed machining with HCC holder has achieved a significant reduction in cycle time.

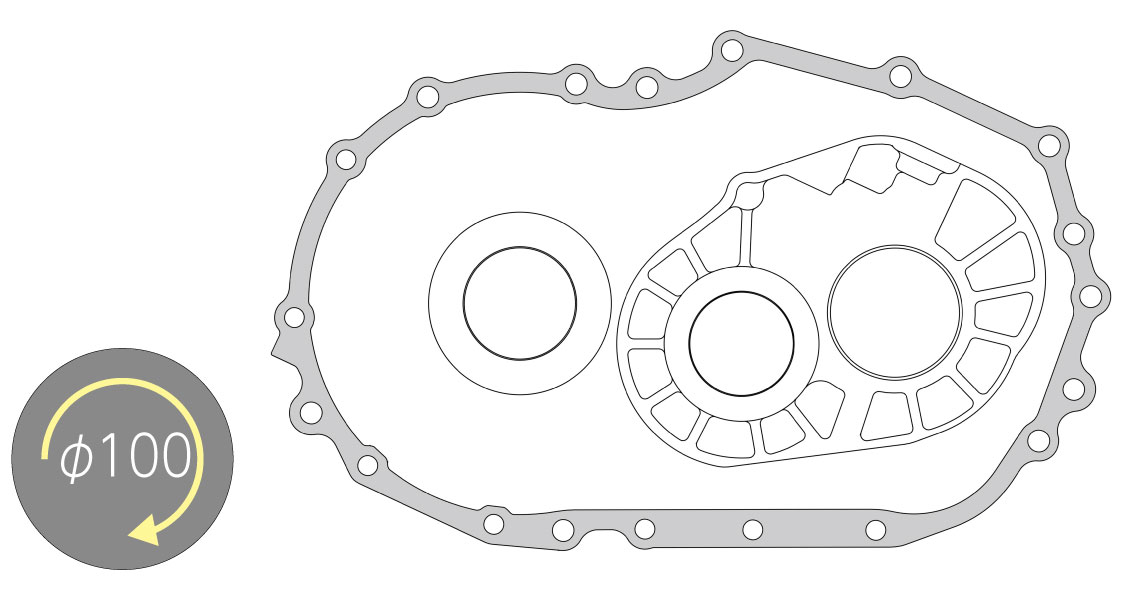

| Transmission case | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

|

||

|

||

| SX6 |

120 pcs / corner

|

|

| Competitor’s carbide inserts |

60 pcs / corner

|

|

As for competitor’s milling cutter, we needed to change inserts to new ones due to the wear progress and lower clamping force of work material after machining 60 pcs.

This was caused by increasing sutting force.

NTK NEW Milling cutter “FU-HA MILL” achieved 2 times longer competitor’s.

Low cutting force avoided the problem occurred by competitor’s milling cutter.

| Feed rate per tooth (mm/t) Feed rate per tooth (IPT) | |||||

|---|---|---|---|---|---|

| 0.1 .004 | 0.2 .008 | 0.3 .012 | 0.4 .016 | ||

| Depth of cut (mm) (inch) |

1 .04 | 4 | 6 | 7 | 9 |

| 2 .08 | 7 | 11 | 14 | 17 | |

| 3 .12 | 11 | 16 | 22 | 26 | |

| 4 .16 | 14 | 22 | 29 | 35 | |

| Feed rate per tooth (mm/t) Feed rate per tooth (IPT) | |||||

|---|---|---|---|---|---|

| 0.1 .004 | 0.2 .008 | 0.3 .012 | 0.4 .016 | ||

| Depth of cut (mm) (inch) |

1 .04 | 3 | 4 | 6 | 7 |

| 2 .08 | 6 | 9 | 12 | 14 | |

| 3 .12 | 9 | 13 | 18 | 22 | |

| 4 .16 | 12 | 18 | 24 | 29 | |

| Feed rate per tooth (mm/t) Feed rate per tooth (IPT) | |||||

|---|---|---|---|---|---|

| 0.1 .004 | 0.2 .008 | 0.3 .012 | 0.4 .016 | ||

| Depth of cut (mm) (inch) |

1 .04 | 6 | 9 | 12 | 14 |

| 2 .08 | 12 | 18 | 24 | 29 | |

| 3 .12 | 18 | 27 | 35 | 43 | |

| 4 .16 | 23 | 36 | 47 | 57 | |

| Feed rate per tooth (mm/t) Feed rate per tooth (IPT) | |||||

|---|---|---|---|---|---|

| 0.1 .004 | 0.2 .008 | 0.3 .012 | 0.4 .016 | ||

| Depth of cut (mm) (inch) |

1 .04 | 5 | 8 | 11 | 13 |

| 2 .08 | 11 | 16 | 22 | 26 | |

| 3 .12 | 16 | 24 | 33 | 39 | |

| 4 .16 | 21 | 32 | 43 | 52 | |

| Feed rate per tooth (mm/t) Feed rate per tooth (IPT) | |||||

|---|---|---|---|---|---|

| 0.1 .004 | 0.2 .008 | 0.3 .012 | 0.4 .016 | ||

| Depth of cut (mm) (inch) |

5 .20 | 36 | 55 | 76 | 93 |

| 6 .24 | 43 | 66 | 91 | 111 | |

| 7 .28 | 50 | 76 | 106 | 130 | |

| 8 .31 | 97 | 149 | 208 | 254 | |

| Feed rate per tooth (mm/t) Feed rate per tooth (IPT) | |||||

|---|---|---|---|---|---|

| 0.1 .004 | 0.2 .008 | 0.3 .012 | 0.4 .016 | ||

| Depth of cut (mm) (inch) |

1 .04 | 9 | 13 | 18 | 21 |

| 2 .08 | 17 | 27 | 35 | 42 | |

| 3 .12 | 26 | 40 | 53 | 64 | |

| 4 .16 | 35 | 54 | 70 | 85 | |

| Feed rate per tooth (mm/t) Feed rate per tooth (IPT) | |||||

|---|---|---|---|---|---|

| 0.1 .004 | 0.2 .008 | 0.3 .012 | 0.4 .016 | ||

| Depth of cut (mm) (inch) |

1 .04 | 7 | 10 | 14 | 17 |

| 2 .08 | 14 | 20 | 27 | 33 | |

| 3 .12 | 20 | 31 | 41 | 50 | |

| 4 .16 | 27 | 41 | 55 | 66 | |

| Feed rate per tooth (mm/t) Feed rate per tooth (IPT) | |||||

|---|---|---|---|---|---|

| 0.1 .004 | 0.2 .008 | 0.3 .012 | 0.4 .016 | ||

| Depth of cut (mm) (inch) |

5 .20 | 61 | 93 | 130 | 159 |

| 6 .24 | 73 | 112 | 156 | 190 | |

| 7 .28 | 85 | 131 | 182 | 222 | |

| 8 .31 | 97 | 149 | 208 | 254 | |

| Feed rate per tooth (mm/t) Feed rate per tooth (IPT) | |||||

|---|---|---|---|---|---|

| 0.1 .004 | 0.2 .008 | 0.3 .012 | 0.4 .016 | ||

| Depth of cut (mm) (inch) |

1 .04 | 12 | 19 | 25 | 30 |

| 2 .08 | 24 | 37 | 49 | 59 | |

| 3 .12 | 36 | 56 | 73 | 89 | |

| 4 .16 | 48 | 74 | 98 | 118 | |

| Feed rate per tooth (mm/t) Feed rate per tooth (IPT) | |||||

|---|---|---|---|---|---|

| 0.1 .004 | 0.2 .008 | 0.3 .012 | 0.4 .016 | ||

| Depth of cut (mm) (inch) |

1 .04 | 8 | 13 | 17 | 20 |

| 2 .08 | 17 | 25 | 34 | 41 | |

| 3 .12 | 25 | 38 | 51 | 61 | |

| 4 .16 | 33 | 50 | 68 | 82 | |

| Feed rate per tooth (mm/t) Feed rate per tooth (IPT) | |||||

|---|---|---|---|---|---|

| 0.1 .004 | 0.2 .008 | 0.3 .012 | 0.4 .016 | ||

| Depth of cut (mm) (inch) |

5 .20 | 93 | 143 | 198 | 242 |

| 6 .24 | 111 | 171 | 238 | 291 | |

| 7 .28 | 130 | 200 | 277 | 339 | |

| 8 .31 | 148 | 228 | 317 | 387 | |

| Feed rate per tooth (mm/t) Feed rate per tooth (IPT) | |||||

|---|---|---|---|---|---|

| 0.1 .004 | 0.2 .008 | 0.3 .012 | 0.4 .016 | ||

| Depth of cut (mm) (inch) |

1 .04 | 21 | 32 | 42 | 50 |

| 2 .08 | 41 | 63 | 83 | 100 | |

| 3 .12 | 62 | 95 | 125 | 151 | |

| 4 .16 | 82 | 127 | 166 | 201 | |

| Feed rate per tooth (mm/t) Feed rate per tooth (IPT) | |||||

|---|---|---|---|---|---|

| 0.1 .004 | 0.2 .008 | 0.3 .012 | 0.4 .016 | ||

| Depth of cut (mm) (inch) |

1 .04 | 12 | 18 | 24 | 29 |

| 2 .08 | 24 | 36 | 49 | 59 | |

| 3 .12 | 36 | 54 | 73 | 88 | |

| 4 .16 | 48 | 72 | 97 | 117 | |

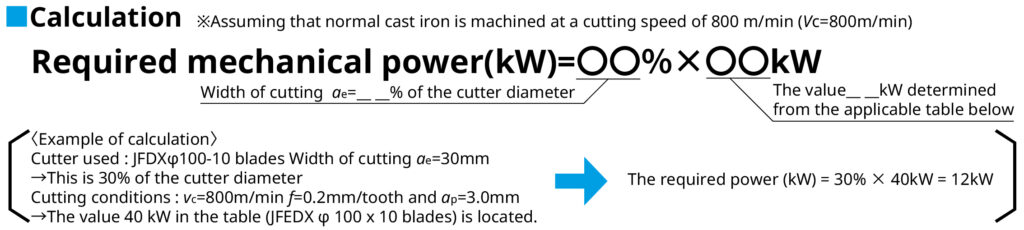

Unit: kW

*Please make use of the above tables, understanding that they are approximations only to use as a guide.

For more information about this product, visit our online e-catalog, or download the catalog/product report