For socket hole machining| Swiss CNC lathes

Swiss CNC lathe socket feature machining

Work Materials

Titanium / Stainless steel / PEEK / TEFLON

| Tool pressure | Cycle time | Flexibility | Tool cost | ||

|---|---|---|---|---|---|

Shaper Duo | ◎ | △ * Can be off-set by overlapping operation | ○ | ◎ | Less tool pressure, especially good for small diameter parts. One insert can machine a range of socket sizes |

| Broach | △ | ○ | ╳ | △ | You need a tool for each socket size |

| Tool pressure | Cycle Time | Tool Cost | High speed spindle | Program | ||

|---|---|---|---|---|---|---|

Shaper Duo | ◎ | ◎ | ◎ | Not necessary | Simple | No need for a high speed spindle Short cycle time |

| Milling | ○ | ╳ | △ | Necessary | Complicated | Requires high speed spindle Time consuming process |

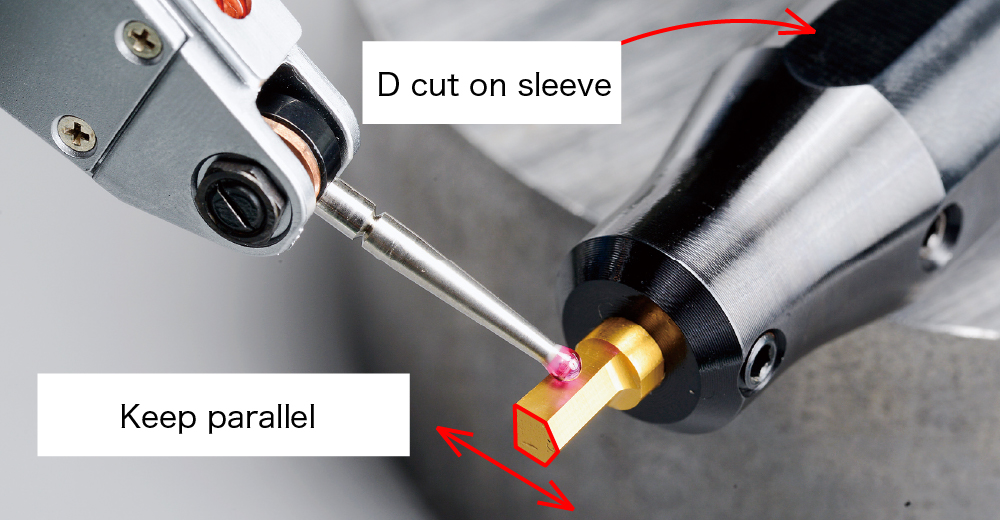

① Insert Installation

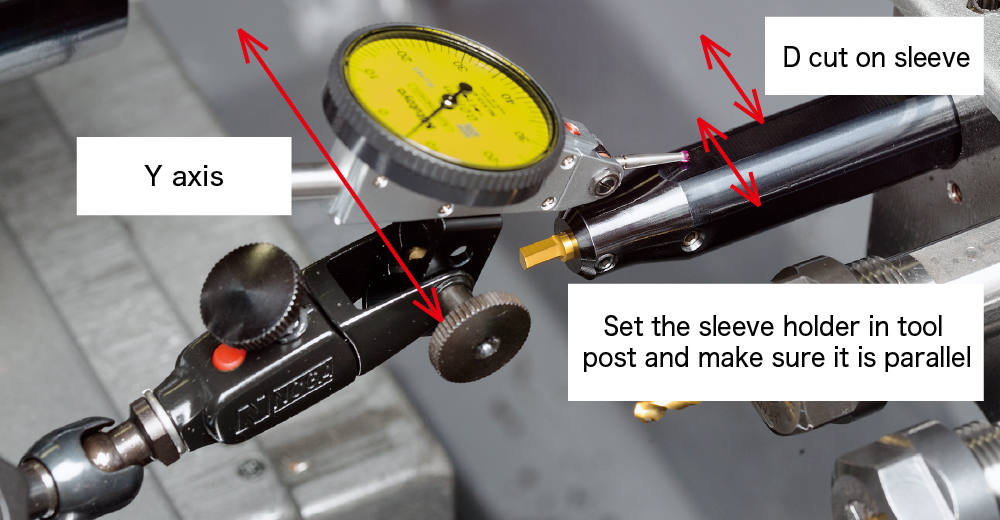

② Make sure the sleeve is set parallel

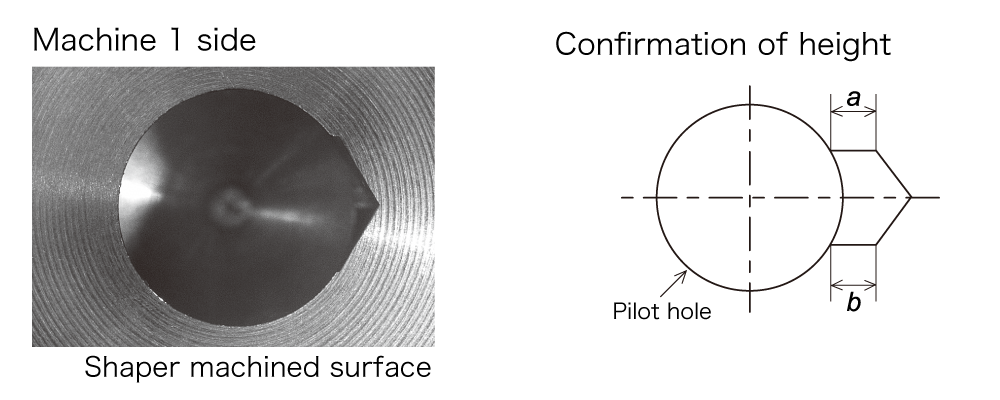

③ Confirmation of height

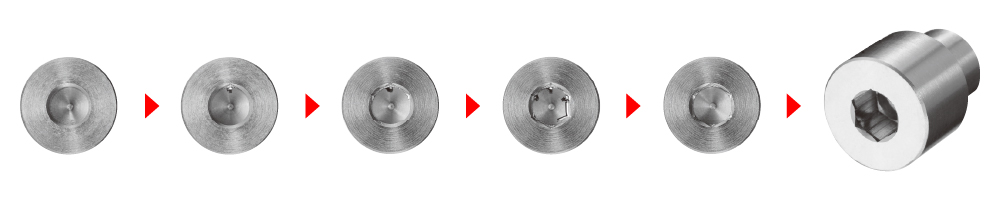

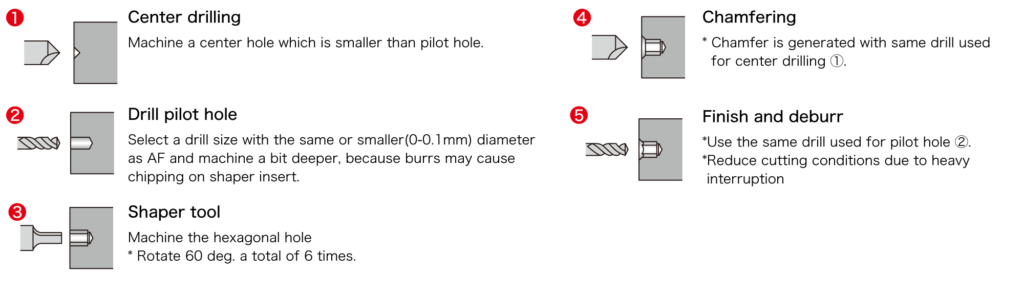

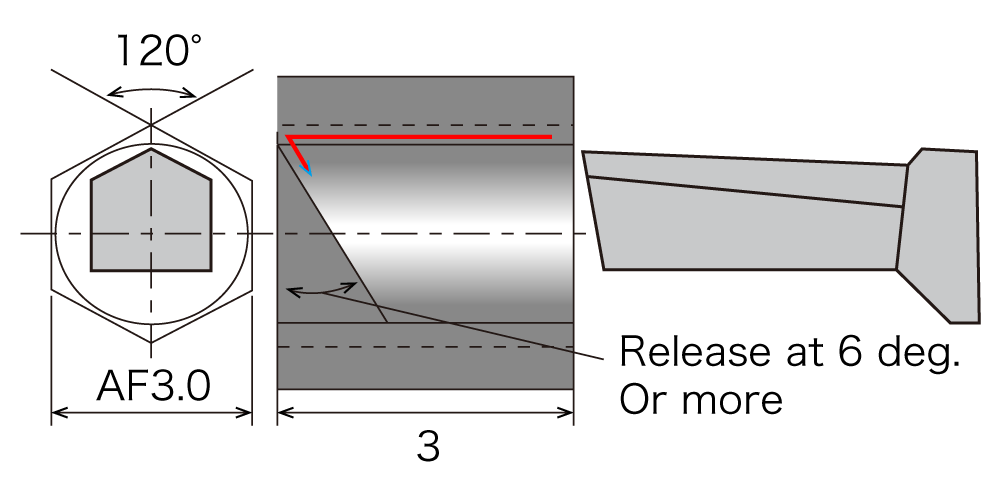

④ Visual of step by step machining of hexagon socket

[ Recommended cutting contitions ]

Feed

1000 to 4000 mm/min

39.3 to 157.5 IPM

DOC: Roughing

0.025mm and Finishing 0.005mm

.0010” and Finishing .0002”

(1 to 2 times)

| Hexagon hole machining | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| TM4 SSP030N1940H |

10,000 pcs / corner

|

| Competitor’s carbide inserts | 300 pcs / corner |

Competitor’s product dulled very quickly resulting in short tool life.

NTK’s hexagon shaper insert achieved longer tool life by maintaining insert edge sharpness and shape.

Improved cycle time and excellent surface finishes.

For more information about this product, visit our online e-catalog, or download the catalog/product report