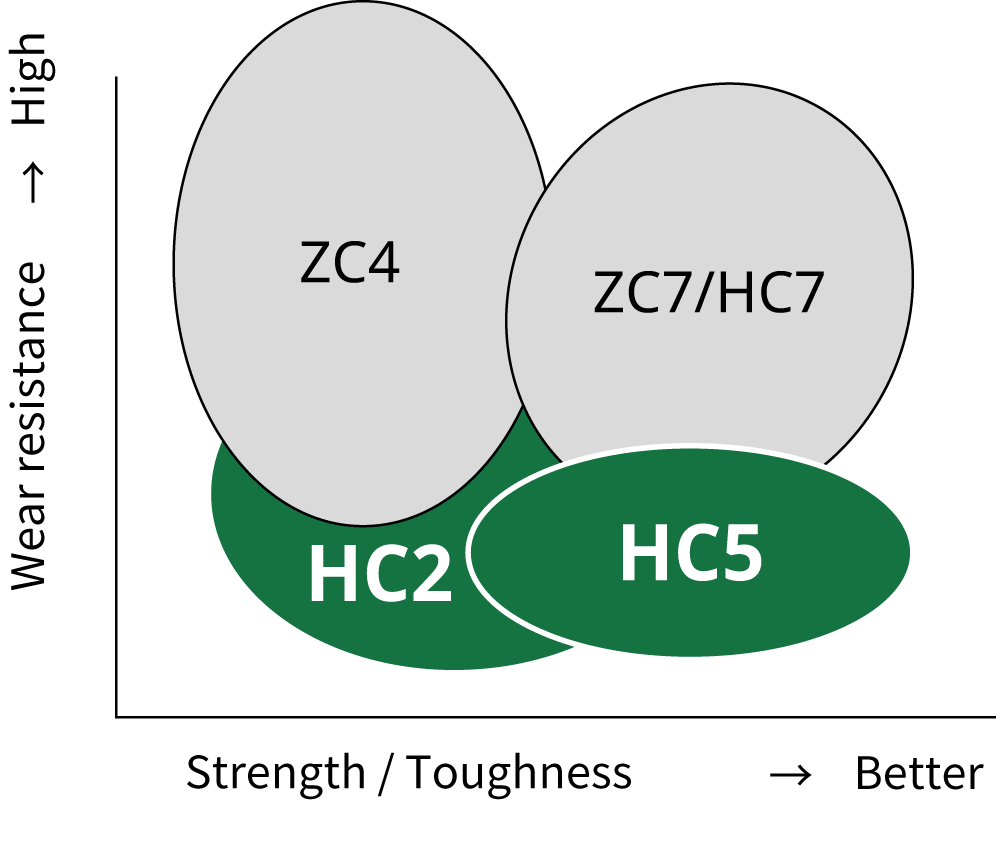

For continuous machining of gray cast iron and hardened materials | Alumina TiC based ceramics

| Grade | Material | Operation type | Machining | Cutting speed (m/min) Cutting speed (SFM) | Feed(mm/rev) Feed (IPR /IPT) | DOC(mm) DOC(inch) | Coolant |

|---|---|---|---|---|---|---|---|

| HC2 | Gray cast iron | Turning | Semi-finishing to finishing of Gray cast iron | 360 – 640 1200 -3300 | 0.1 – 0.4 .004 – .016 | -1.5 – .059 | DRY / WET |

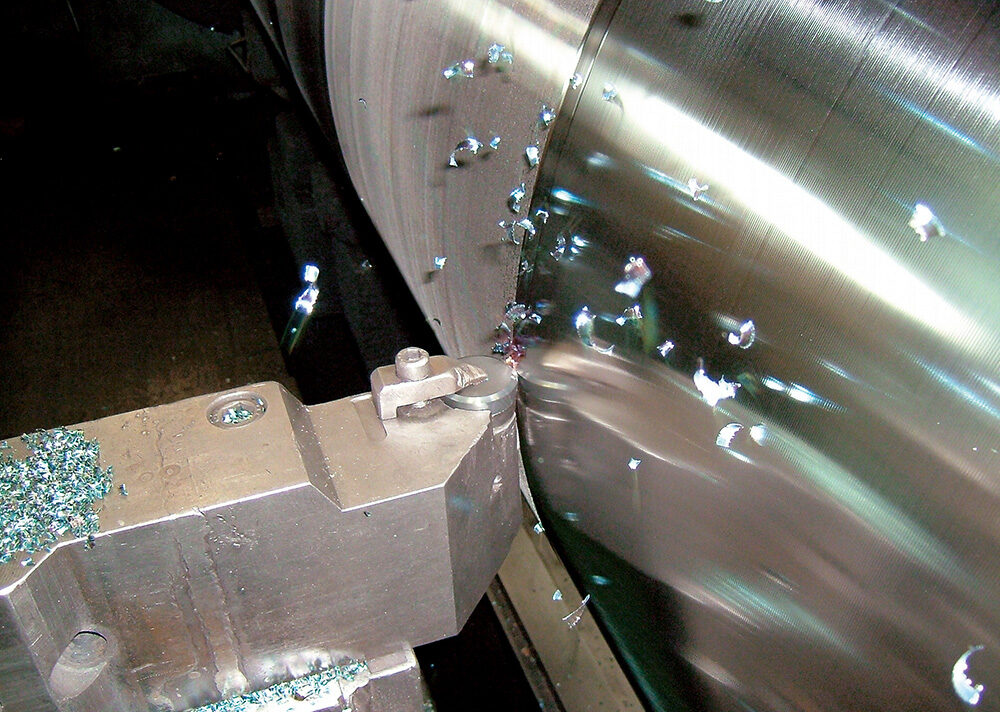

| HC5 | Chilled cast iron | Roughing to finishing of cast iron and steel mill rolls | 90 – 180 300 -600 | 0.1 – 0.3 .004 – .012 | 0.6 – 1.9 .024 – .075 | DRY |

| Cylinder liner | ||

|---|---|---|

|

|

|

|

||

|

||

|

||

|

||

| HC2 |

110 pcs / corner

|

|

| Competitor’s carbide |

40 pcs / corner

|

|

HC2 achieves 1.5 times higher machining efficiency and nearly three times longer tool life than other competitors’ carbide.

For more information about this product, visit our online e-catalog, or download the catalog/product report